Hello All,

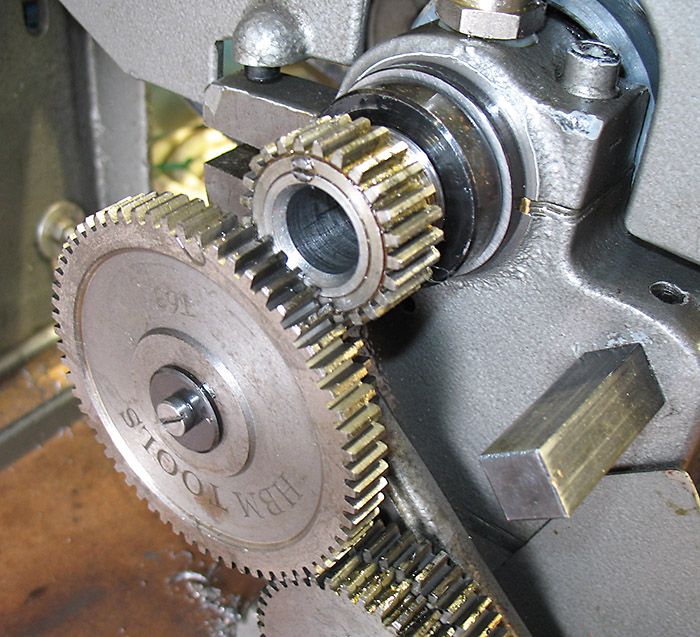

I cleaned off the black grease and found the 2BA grub screw, Took this out and the 35 T gear slid off. The reason that the 35T gear would not move further to the right was then clear. It was in fact hard against the shoulder of the raised thread on the mandrel (presumably this thread is used to tighten the mandrel bearings). Looks as if the mandrel has somehow been moved bodily to the left!

So I would appear to have a limited range of options,

1/ Remove the mandrel and see if it can be moved to the right.

2/ machine the 35T bearing so that it can clear the threads on the mandrel. Would only need boring out by about 3mm.

3/ Reduce the entire width of the 35T wheel by the same 3mm. Interestingly enough the width of the 35 T gear is markedly greater than any of the change wheels,

4/ Make up some washers to fit the banjo studs and hence move all the banjo gears to the left.

Not keen on 1/ until I need to change the drive belts. 4/ could be a problem as I suspect the screw and retaining washers would need shimming out to match.

I am tempted to go for 2/ as it is the least intrusive.

Hopper, the set up should be clear from the photos that Jason posted. The Banjo is as per diagram in the handbook. The only thing I have not checked is if there should be a spacer washer between the Banjo and the lathe bed. This would move the banjo to the left and solve the problem. But not sure if the last gear on the banjo train would line up correctly with the leadscrew gear. I will check and get back to you. b

The textbook picture posted seems to have a 25T gear, not your 35T gear, and seems to mesh perfectly with the one gear. It would seem yours has something different, somewhere.

I would certainly be investigating banjo spacer before i started looking at moving your headstock spindle to the right to bring change gears into alignment. Sledgehammers and gnats come to mind.

If you move the banjo outwards by the requisite amount, you should be able to move the leadscrew gear out by the same amount too. It is only held on the shaft by a key and those sliding collars with grub screws.

Or it could be a matter of spacer washers on the studs behind the gears.

Or it could be that your 35T gear is wider than the 25T gear in the posted picture above.

Or it could be the 35T gear, which is threaded internally, has not been screwed far enough onto the headstock spindle before the locking grub screw was installed to lock it in position.

Or it could be something else.

Obviously, you are not seeing what the problem is. But someone else might if you could post some pics of what is actually going on on your lathe.

Howard Lewis.