Thanks for that info Nick, but I have had a Eureka moment!

After taking the motor apart once more to get at the wires there was about 7 ohms on one winding and 10 across the other, so I wired accordingly, the only difference between the wiring now is I have taken the thermal switch out of circuit.

Anyway, plugged it in switched on and heh presto! it worked! repeated this several times just to check it wasn’t a fluke, after assembly of pulley, belt and terminal cover – no go again.

Exactly as before, give it a spin (any way) and off it goes, but sometimes it would start.

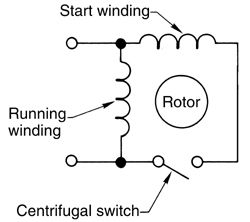

I could hear the centrifugal switch operating as the motor got to speed, but I found that if it was switched on and didn’t start the slowest of rotation would be enough to get it going, I shone a light into the motor and could see that as the motor came to a halt the start swich contacts were being ‘massaged’ and depending on where it stopped it would allow contact to be made, or not!

I believe the problem is that the centrifugal part on the armature only has one point of contact with the switch ‘ring’ that it touches and therefore causes the above mentioned ‘massaging’ effect to the contacts – which have obviously worn

I think the design could have been better with 2 points of contact to the switch ring to minimise contact wear – not sure if I can do anything about it easily as they appear to be spun into position!

Alan

Nicholas Farr.

Nicholas Farr.