Hi

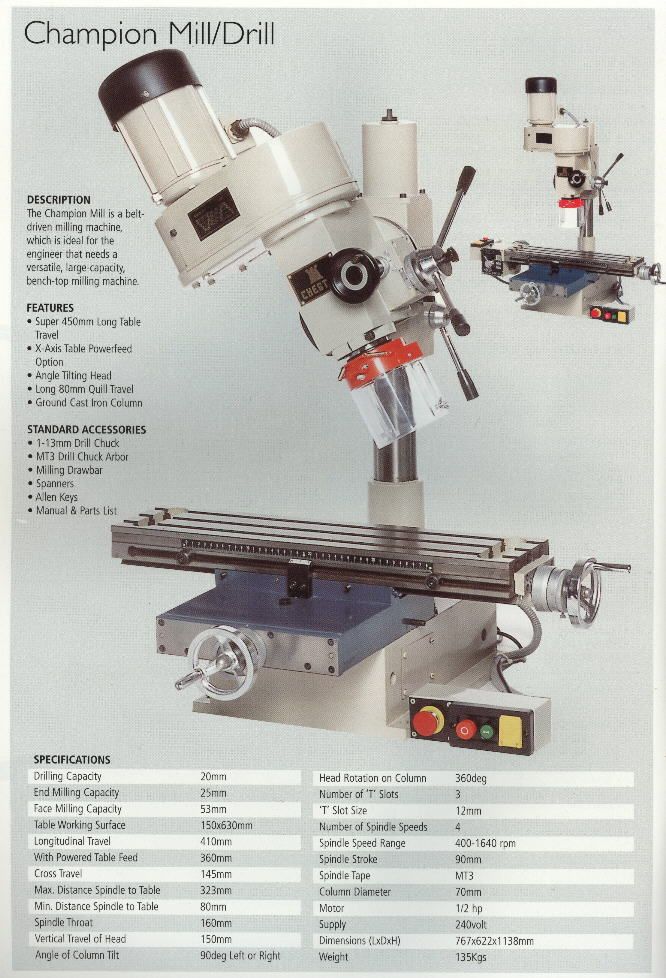

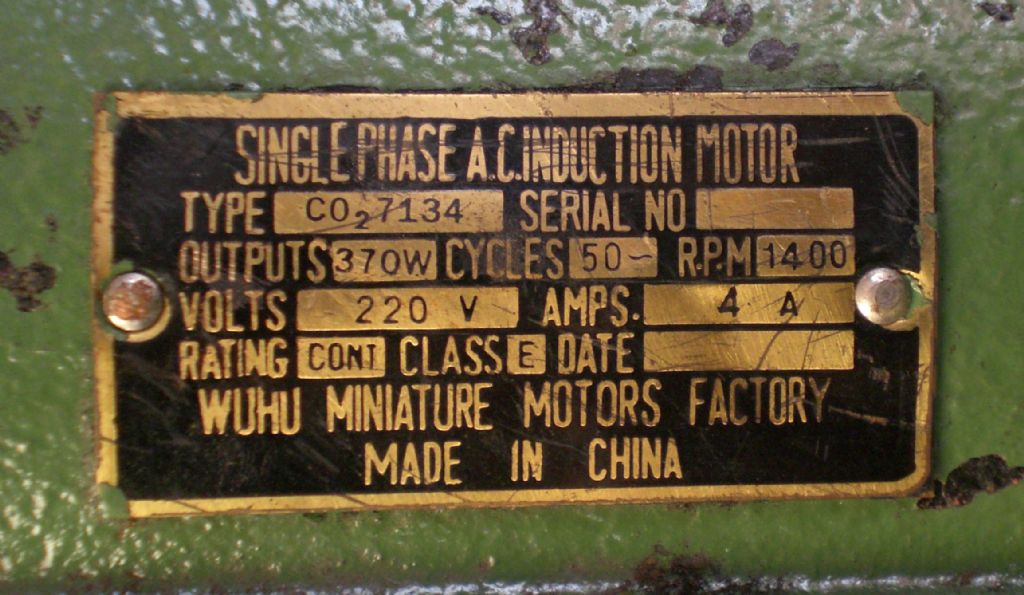

The motor on the Chester Champion Mill, if the same as the items now offered by Chester, is a DC motor which is driven from a speed controller. The problem with these motors is that if they are driven moderately hard at low speeds then the armatures tend to over heat and the windings fail. It would seem that the motor's internal fan is not particularly effective even at normal speeds and virtually ineffective at low speeds. This is compounded by the fact that the effective I2R losses/heating can increase if the motor is loaded at lower speeds when the fan is not performing thereby making the problem worse.

This problem has been subject of several threads on the forum at the Chester web site. I believe that virtually all mills/lathes using this type of drive, irrespective of supplier, are susceptible to this problem. One way to alleviate this would be to fit a small computer type of fan to the motor in order to increase the airflow, however there will be flow conflict if the motor is run in reverse  .

.

I have a mill and lathe that use similar motors and to date while they have got quite warm they haven't, as far as I am aware, overheated significantly. There may be some merit in running the motor at full speed with no load for shortish periods of time when it is being used for longish periods. An ad-hoc form of duty cycling in order to remove some of the heat.

I have run both the mill and lathe for periods in well excess 30 min with no problems. I tend to use the lowest (back) gearing so that the motor runs as fast as possible for a given spindle speed.

Cheers

Martin

Edited By Martin W on 27/03/2013 16:59:22

Edited By Martin W on 27/03/2013 17:05:15

Former Member.