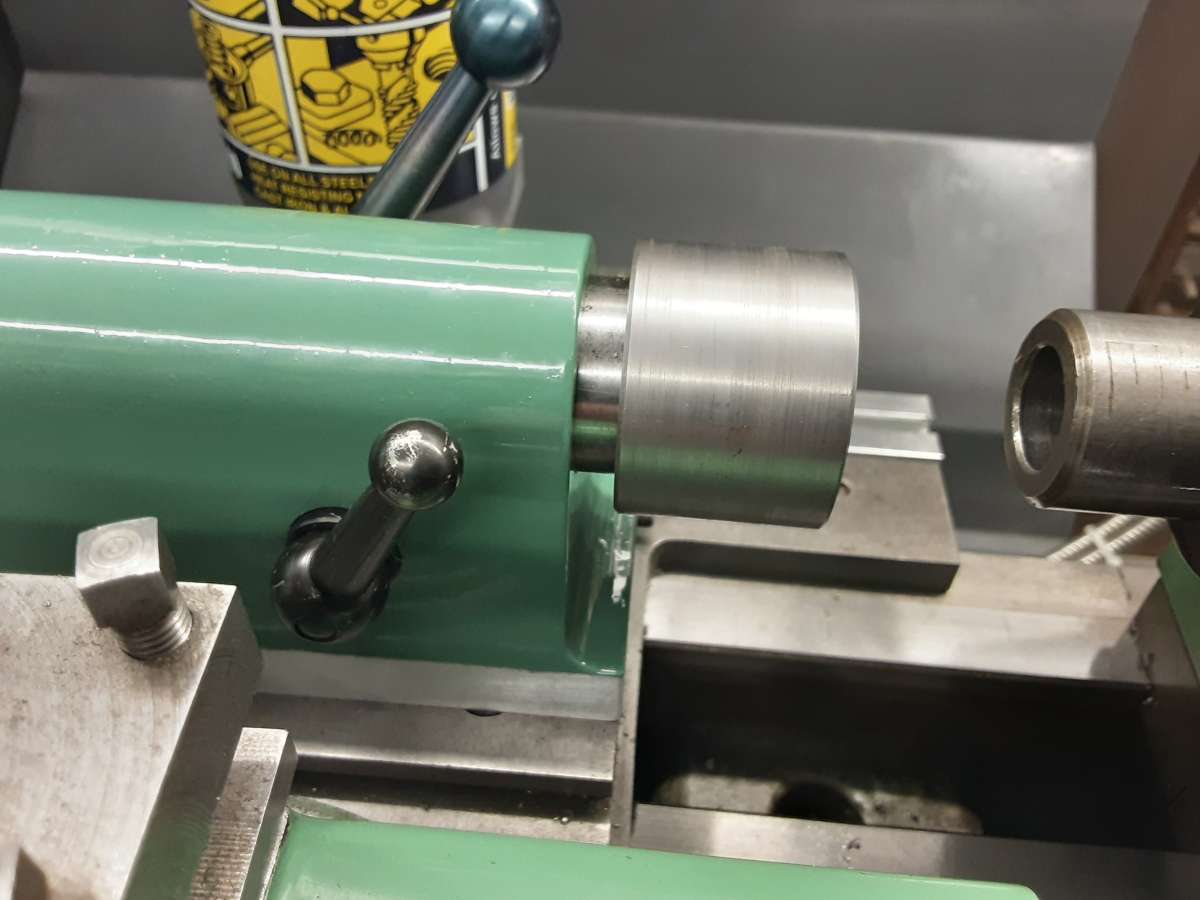

I did include a tang slot in the spindle of the attachment.

The working surface of the Morse taper on my Myford lathe is quite short compared to other machines I’ve used, another reason for making the attachment.

As I stated in my original post, in industry some of the larger drills have their tangs completely missing and are still in use , usually the Heel of these drill are also worn , possibly one cause for the tangs being missing.

I first operated a DSG lathe when I was a Lucas apprentice in Birmingham, they had an immaculate machine with preselect spindle speeds ,the luxury of changing speeds while the spindle was running ,it also had a rapid traverse on the saddle and cross slide operated by a joystick on the front of the saddle . After completing my apprenticeship I worked at the Lucas Lighting factory in Cannock, the toolroom had three DSG lathes all with power drilling attachments , two as DC31K describes and one with a holder that fitted on the tool post.

That’s why the design for the attachment looks similar to a DSG attachment, about 40 years ago I also made a tool post and holders similar to a DSG.

Steve

SteveP.