Posted by blowlamp on 19/05/2023 13:56:43:

Dave.

When you said this:

"MOI is good at curves, making it an excellent choice for 3d-print modelling. Also photo-realistic images, and designing decorative objects. It also appears to be easy to learn, and can do flat stuff as well. All considerable advantages if that's what's needed, but not for me. My needs are more 'mechanical engineering' , and although Solid Edge has surface tools that can do similar to MOI, I've never used them."

I must point out that MoI doesn't do photo-realistic images at all and it's not advertised anywhere that I know of for designing decorative objects, although you could do that if you wanted to.

MoI is perfectly capable of creating an accurate model of anything from a vase to a jet engine, but not in a parametric way. This is why it can export in SAT, IGES and STEP formats, etc. The v5 beta that I'm running also uses the ACIS modeling kernel as well as Solids++.

I'm fairly sure that the need to use surfaces will creep up on you as your designs change.

Martin.

Have you read the MOI blurb, or looked at the Gallery Martin? MOI say, my bold: 'Focused on being easy to use, it's a great tool for designers and artists who want to construct accurate models.' Designers and artists rather than engineers. Examples:

The last MOI example represents a record turntable. It's a broadly correct and scaled external view that could be 3D printed as a model, used to illustrate a forum post, or published in a glossy magazine advert.

Great, so far as it goes, but tell me if I'm wrong: the turntable isn't an engineering model. It's an outer view of a turntable with nothing inside.

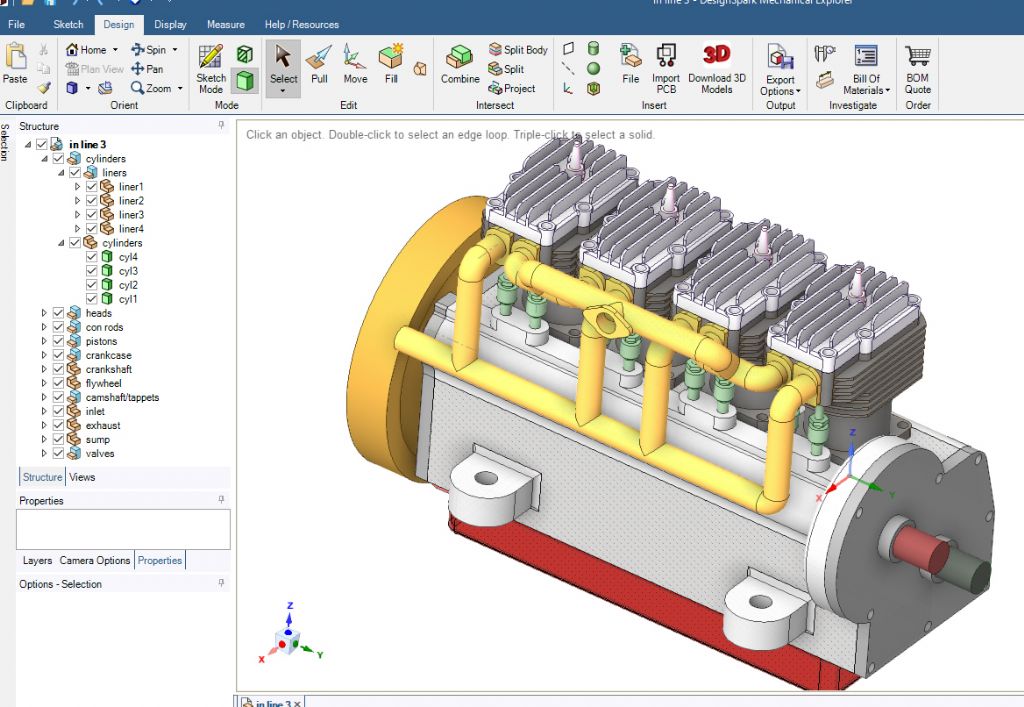

Alibre, SE, and Fusion are different. They get outer appearance almost as a side-effect of modelling all the internal parts. This type of CAD models engineering assemblies, where each part, maybe thousands of them, are designed sufficient to make or source a real one. There would be a motor, drive train, arm-linkages, and all the other fixtures and fittings necessary to make a real turntable, positioned inside the outer casing. The model will often include trivia like washers, bearings, o-rings, fuse-holders, and cable clips etc. so the overall weight is always known, and a full BOM available.

This type of CAD modelling is much more focussed on getting the engineering detail right than look, which is added later. The model of the arm assembly would be accurate enough to confirm that the counter-weight correctly balanced the cartridge, and also to swing across the record with the necessary geometry. After that the shiny good looks depicted by MOI are paint, putty and polish.

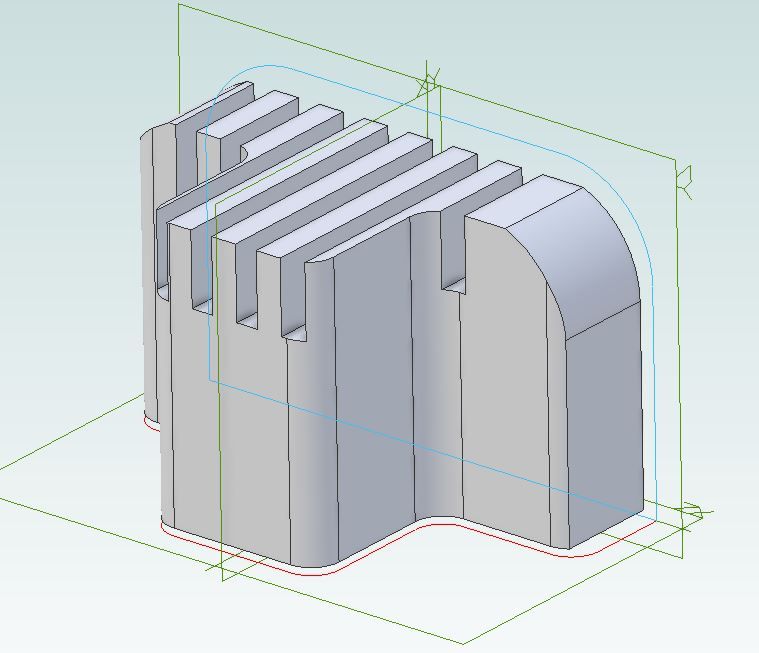

MOI focusses on selling, whilst parametric CAD focusses on manufacture. Both are important. The MOI turntable model has many features designed to make it look top-quality hi-tech, but which are unlikely to be functional. MOI is top-notch for that, hi-fi fanboys would buy that turntable I'm sure. My sort of CAD model focuses on the practical, where the MOI's sexy rear 'heat-sink' is implemented as some chrome-plated plastic fins stuck on the back, whilst the engineering design uses intelligently sized standard items clipped on the transistors. MOI doesn't need to model the heat capacity of heatsinks, modelling for production does.

There's a lot of overlap between the two approaches, but MOI punches hard at the artistic end, whilst Alibre and friends concentrate on engineering. In the middle both tools produce similar results, but I don't think MOI can model a jet engine as an assembly. How about a working lazy tong?

Dave

lee webster.