Posted by Dave Smith 14 on 08/04/2022 23:05:41:

Luker

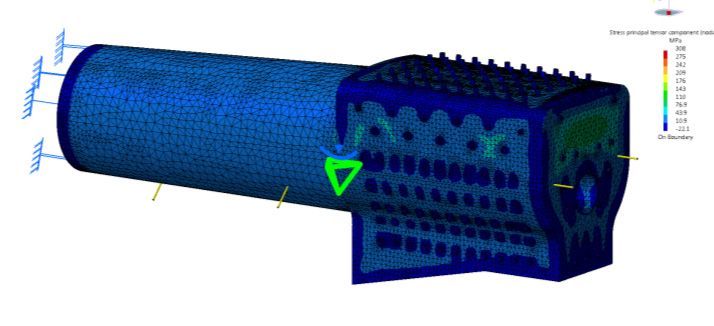

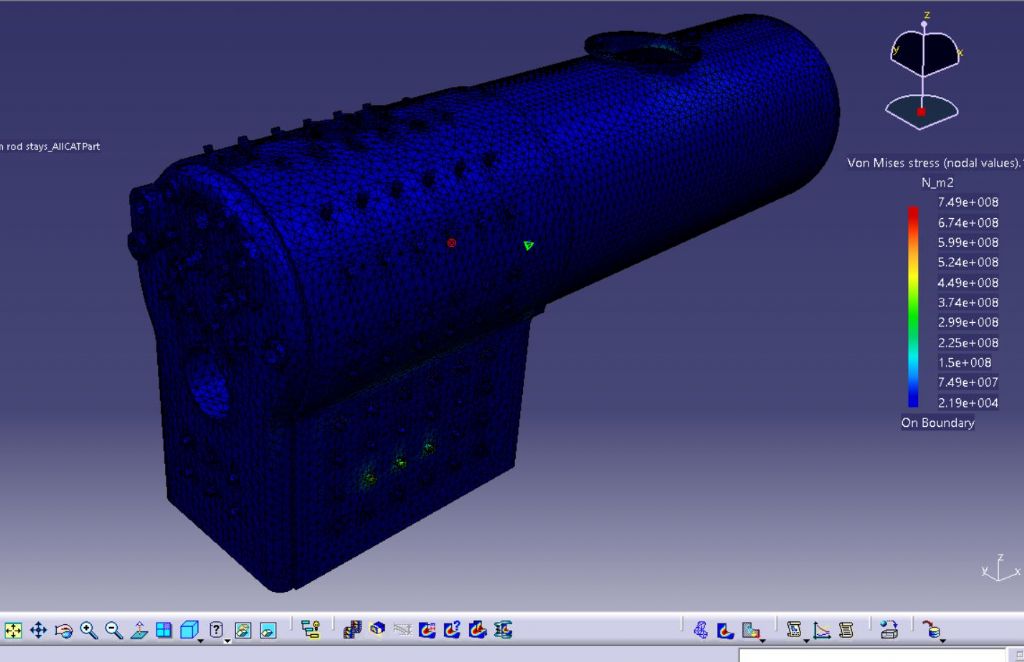

Similar to you I used FEA on ME boilers. First photo a section…

Hi Dave,

Steel boilers tend to solve nicely in FEA, they don’t have the non-linear material properties typical with copper. Your simulations look good, and it’s good to know that other model engineers are using modern techniques to move the hobby forward!

It’s interesting that you also found the (crown) rod stays in the Aussie code to be marginal. For the Stirling mentioned in the article (my avatar loco) I built the boiler to that code using crown stays and I also found the code to be marginal (in fact there’s a few aspects of that code that can be improved upon). I also had to do a little redesign in this area. The crown stays are stronger and all my later boiler designs use this configuration.

I think the problem with crown stays comes from the old days where the silver solder came loose with subsequent heating, but with welding this is not a problem. I’ve also seem two boilers recently where the cross strut was left out, and the comment was that little plate does nothing. Took a little explaining as to why that little plate is so important for the crown stay!

For the record, I don’t want to create the impression that all boilers need to be verified with FEA. If the design is published, or proven and built to the drawings then no calculations are needed and you have to assume the designer has done his bit. The only reason I have had to use FEA in my designs is because they use materials and manufacturing techniques not commonly used in ME.

Luker.