Model Turbines

Model Turbines

Home › Forums › Stationary engines › Model Turbines

- This topic has 606 replies, 28 voices, and was last updated 12 July 2025 at 16:28 by

Turbine Guy.

-

AuthorPosts

-

24 May 2020 at 20:48 #474620

Robert Atkinson 2Participant@robertatkinson2

Robert Atkinson 2Participant@robertatkinson2Hi,

My background is electronics so I tend to look in that direction for solutions. A brushless DC would act like a 3 phase alternator so a little harder to instrument. Known propellors are a useable solution and are used to check full size aircraft engines. These are normally special item with short blades and are called "club" propellers as they look more like clubs than blades. There is a document on their calibration here:

https://www.casa.gov.au/files/003pdf-13

(I'm in aviation)Robert G8RPI.

25 May 2020 at 17:49 #474856Turbine Guy

Participant@turbineguyHi Robert,

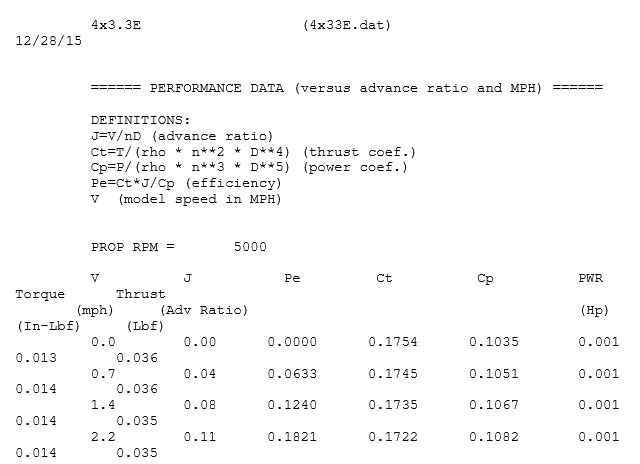

I followed your link and read the report. This is similar to the way I find the power using propellers with performance given for various speeds. The following is a portion of the performance sheets given by APC for the 4×3.3EP propeller I use for testing with steam. The performance is given for several speeds and, as I noted in my test sheets, the power coefficient is the same for speeds ranging from 5,000 rpm to 10,000 rpm. With the assumed air density, propeller diameter, and power coefficient remaining constant, the power is proportional to the cube of the speed. Since the static power given by the table is approximately 0.77 watts at 5,000 rpm, the power at speeds up to 10,000 rpm can be found by the following equation.

P=0.77(N/5,000)3

Where: P = Power required to turn the propeller at the speed N, watts

N= Propeller speed, rpm.29 May 2020 at 14:21 #475882Turbine Guy

Participant@turbineguyI decided to try to fix the relief valve on my smallest boiler. I used the methods I discussed in the post of 25/03/2020 in this thread shown in this link https://www.model-engineer.co.uk/forums/postings.asp?th=140195&p=8. The repair of the relief valve was a complete success using these guidelines. The boiler does not leak any steam until the relief valve starts to open at about 32 psig. Before repairing the relief valve it was starting to leak before the boiler reached 20 psig. The following picture shows my Turbine 2 connected to this boiler and the wick type burner I use. As you can see in the photo, there is no stop valve used, so the turbine inlet gets almost the full pressure of the boiler. For the test I ran after fixing the relief valve, I did the following. I put a carefully measured ½ cup of water in the empty boiler. I added the ball bearings I’ve been running with Krytox GPL 105 oil in my turbine after adding a slight amount of this oil to each bearing. I then filled the wick burner with denatured alcohol, lit it, and set it in the boiler. It took a few minutes for the steam to start coming out but then reached the maximum pressure of 25 psig in a short time. The pressure remained constant until the boiler ran out of water in approximately 12 minutes. The turbine speed took several minutes to reach it’s maximum speed of 17,000 rpm but held approximately that speed for the rest of the test. The mass flow is 1.30 lb/hr and the power required for the GWS EP 2508 propeller I used in the test is approximately 0.9 watts at 17,000 rpm. The mass flow was about what I was getting running my turbines on the small boiler before the relief valve started leaking. The power was less running on steam from my small boiler than what I have obtained running on air with Turbine 2 (0.9 watts vs 1.4 watts). I’ll see if I can explain the lower performance in my next post.

30 May 2020 at 18:08 #476161Turbine Guy

Participant@turbineguyI thought the reason for the drop in performance of Turbine 2 running on steam versus running on air was the viscosity of the Krytox GPL 105 oil I use with steam. This oil is approximately 6 times more viscous than Krytox GPL 102 oil at 212 F (100 C). I ran another test of Turbine 2 identical to the test in the last post except that I did not add any oil to the ball bearings. The turbine obtained the same 17,000 rpm maximum speed of the last test, but the speed slowly dropped to approximately 16,000 rpm at the end of the test. The vibration increased as the speed dropped. I use the stopwatch feature of my watch to time the runs, but I failed to hit the stop button at the end of the run, so I didn’t get the mass flow. I then made a test with Krytox GPL 102 oil added to each ball bearing before starting the test. The maximum speed reached was approximately 16,000 rpm and the speed also decreased slowly as the run continued and the minimum speed was approximately 15,500 rpm. The vibration was very high for the second test. The pressure remained at about 25 psig for the entire length of both tests. I did hit the stop button on the second test, but something started the stopwatch again, so when I looked at the elapsed time it was way over the length of the run. I take the burner out of my boiler immediately after it runs dry, so I didn’t check the elapsed time until I started to record the data. Normally my watch will keep the elapsed time until I restart the stopwatch, so I must have bumped the button. Anyway, I didn’t get the mass flow for either of these runs. These tests indicated that vibration is a major part of the loss in performance. I knew the rotor of Turbine 2 has the worst balance of any of my rotors, but I didn’t realize that it could result in this large of a power drop. When I first put a shaft in the cast rotor Werner Jeggli gave me, I was anxious to test it and ran the test before balancing the rotor. The maximum speed running on air for the unbalanced rotor was 18,000 rpm. The maximum speed running on air for the balanced rotor was 21,500 rpm. This is an increase in power of approximately 0.8 watts due to balancing. I ran my Turbine 2 on air with ball bearings containing the Aeroshell Fluid 12 oil that I normally use. These were the same bearings and oil used in the tests of the cast rotor. The maximum speed was approximately 18,000 rpm and there was very little vibration. Apparently, the Aeroshell Fluid 12 oil has a better balance of power lost due to viscosity and power loss due to rotor unbalance running on air than either of the Krytox oils running on steam. The 18,000 rpm running on air, is not as high as the maximum speed of 19,500 rpm I have already obtained with Turbine 2 and Aeroshell Fluid 12 oil. About all I can confirm with these tests is the importance of the oil in the ball bearings. The oil needs to be correct for the gas and temperatures used and needs to be freshened each run for maximum performance.

30 May 2020 at 18:31 #476175Tim Stevens

Participant@timstevens64731I wonder. A turbocharger uses 'spare' power from exhaust gas to compress gas to 'overfill' the engine cylinders, using a turbine to drive a turbine. There is not much difference between waste exahaust gas and steam – not so hot, wetter, certainly, but in principle one hot gas is much like another. Is there any reason why the exhaust half of a turbocharger should not serve as a turbine to drive a (small) vehicle? A purist would say that this is not proper model engineering, perhaps – but has anyone tried it?

Cheers, Tim

30 May 2020 at 19:15 #476186Turbine Guy

Participant@turbineguyHi Tim,

The following link shows what a Mechanical Engineering student did trying to accomplish what you suggested.

https://dspace.mit.edu/bitstream/handle/1721.1/32971/62861135-MIT.pdf?sequence=2

1 June 2020 at 13:35 #476669Turbine Guy

Participant@turbineguyI ran a test with my smallest boiler and the cast axial rotor to see if the steam output of the small boiler was part of the problem. I used this rotor since the position can be adjusted to allow space for the steam to go supersonic before contacting the rotor. The ability to do this has made this rotor perform better than my tangential flow rotors with steam even though the open pocket rotors have done better on air. I added a carefully measured ½ cup of water to the empty boiler and placed the lighted wick burner in the boiler. I started my stopwatch after the steam started flowing from the turbine and noticed it took approximately a minute to reach the maximum pressure of 25 psig. The pressure stayed at 25 psig for the total time of the run. The boiler went dry after approximately 9 ½ minutes. There was a large drop in speed for a few seconds that indicated a slug of water got into the steam line. The resultant mass flow is 1.64 lb/hr but the carried over water invalidates this result. The maximum speed obtained was approximately 18,000 rpm and the vibration was fairly high even though this is my best balanced rotor. This indicates that the bearings may be the problem. I will change the ball bearings and see if I can get a run without water getting into the steam line.

3 June 2020 at 13:16 #477213Turbine Guy

Participant@turbineguyI ran several tests on steam with the same ball bearings and using Krytox GPL 105 oil. I add a small amount of the oil to the shields of both ball bearings before each test. On all tests, the maximum speed of the turbine was reached after the turbine housing got hot enough for the oil to get up to its operating temperature and the oil on the outside of the bearings to seep in. When the oil reaches the optimum amount inside the bearings, the turbine speed would stay approximately at the maximum speed for the rest of the test. This worked for every test until I tried running the second test with my Turbine 2 described in the post of 30/05/2020. This was the first time I did not add a small amount of oil to each ball bearing before starting the test. Failing to add the oil before the test and running the rotor that had the worst balance rigidly clamped to the base plate, may have ruined the ball bearings.

4 June 2020 at 14:01 #477454Turbine Guy

Participant@turbineguyI got my new ball bearings and ran a test with air, the cast axial rotor, and the GWS EP 2508 propeller. The maximum speed reached was approximately 24,000 rpm. This was about a 1,000 rpm higher than I was able to get with the bearings that had several hours of running time and had never been exposed to steam. The loss in power after several runs on air is about 0.3 watts. I don’t plan on running on steam for a while since the test results with air are much more consistent and the runs are much easier to do.

20 June 2020 at 12:04 #481053Turbine Guy

Participant@turbineguyIn the post of 29/05/2020 at the following link https://www.model-engineer.co.uk/forums/postings.asp?th=140195&p=9 I stated: ‘The power was less running on steam from my small boiler than what I have obtained running on air with Turbine 2 (0.9 watts vs 1.4 watts)”. The following post from my Testing Models thread at https://www.model-engineer.co.uk/forums/postings.asp?th=139899&p=5 showed similar results for a small oscillating cylinder steam engine running on my small boiler. In that post I showed that the power of the Miniature Steam Models (MSM) Tyne, described below, was less running on steam than what I had obtained running on air (0.7 watts vs 1.1 watts). In both cases, the power running on steam was approximately 64% of the power running on air. The Reynold’s number losses appear to be a major part of this drop in power.

5 September 2020 at 12:08 #494330Turbine Guy

Participant@turbineguyAfter failing to be able to show that the loss in performance running on steam instead of air was due to Reynolds number losses, I thought I would look at the losses due to moisture. I assumed the moisture losses were negligible when using my smallest boiler because I had documented that the steam coming out of the nozzle was completely invisible when I previously tested nozzles with this boiler. Since I am planning to try a larger nozzle to see the effects of running at a lower pressure, I made a nozzle that could be slipped into a hose and tested with my smallest boiler. When I ran a test with this nozzle, the steam exiting the nozzle was completely invisible even at a distance from the nozzle. No moisture was evident in the air or on the surface below the nozzle. This is what led me to believe the steam would stay dry until it passed through the turbine rotor. I didn’t think there was enough time for heat transfer to the turbine housing and turbine rotor to raise the moisture content significantly. Since the cover plate I use for running my axial turbine has the nozzle in it, I decided to run a test using the cover plate shown in the following photo. Running the steam through the cover plate only, allowed me to observe the steam exiting the nozzle and there was more mass to absorb the energy. Unlike the test with just the nozzle only, the moisture was very visible with drops of water on the cover plate and the floor.

Apparently, the steam can be cooled enough to increase the moisture considerably if the cover plate and housing are not insulated. My turbine tests are a worst case for this because the turbine housing and cover plate have a lot of mass and the propeller blows cold air over the uninsulated housing. The run time to empty the boiler that contained a carefully measured ½ cup of water, was 10 minutes and 59 seconds. The run time for this same amount of water in a previous test was 10 minutes and 56 seconds. The mass flow of 1.4 lb/hr for both these tests was very consistent and the pressure stayed at 20 psig for almost the entire time of both tests. The best estimate I could make of the amount of moisture based on the nozzle size and this mass flow, is approximately 20% moisture. This amount of moisture reduces the power considerably and might explain the drop in performance running on steam instead of air.5 September 2020 at 13:51 #494336

Apparently, the steam can be cooled enough to increase the moisture considerably if the cover plate and housing are not insulated. My turbine tests are a worst case for this because the turbine housing and cover plate have a lot of mass and the propeller blows cold air over the uninsulated housing. The run time to empty the boiler that contained a carefully measured ½ cup of water, was 10 minutes and 59 seconds. The run time for this same amount of water in a previous test was 10 minutes and 56 seconds. The mass flow of 1.4 lb/hr for both these tests was very consistent and the pressure stayed at 20 psig for almost the entire time of both tests. The best estimate I could make of the amount of moisture based on the nozzle size and this mass flow, is approximately 20% moisture. This amount of moisture reduces the power considerably and might explain the drop in performance running on steam instead of air.5 September 2020 at 13:51 #494336SillyOldDuffer

Moderator@sillyolddufferPosted by Turbine Guy on 05/09/2020 12:08:22:After failing to be able to show that the loss in performance running on steam instead of air was due to Reynolds number losses, I thought I would look at the losses due to moisture…

We can be confident steam should produce more power than compressed air because it contains much more energy. Something is wrong, a few possibilities, perhaps acting together:

- Is your steam really steam at the boiler? First thing to come off a boiler is a mix of water droplets and water vapour. It has low energy content due to being not hot enough. With rather a lot more heat water changes state into true steam. At low temperatures and pressures still wet, only at high temperatures is steam completely dry. Unless the boiler has a super-heater, the steam will always be a bit wet, and a poor boiler will produce very wet steam.

- The pipework and valves between boiler and turbine leak heat, causing dry steam to convert back into wet steam or actual water. Short well-lagged pipes are needed.

- The turbine is a hefty heat sink. Even if well-insulated, it has to be warmed up to steam temperature before running a test otherwise it will remove energy from the steam and gum the turbine up with water. Rather than outputting power to the shaft, the turbine becomes a water-pump. Although the propeller dynamometer suggests low output, the turbine's actually doing much more work than it did on compressed air, sadly it's all going to waste.

- Possibly the turbine suffers extra friction due to differential expansion. If the rotor is hotter than the case, the two may foul. The rotor's certainly likely to hit solid water if any condensation occurs. Again, the cure is to make sure the turbine is hot enough to prevent condensation before running the test.

I think your turbine will perform much better after it's been thoroughly warmed up and fed dryer steam. A water trap in the pipeline would stop slugs of water getting into the turbine.

Hotter the better. Steam coming out of the turbine should still be well above boiling point. The trick is to extract the remaining energy, which is significant, by deliberately condensing it. A proper condenser creates a vacuum equivalent to up to an extra 14psi on the input, ie your 25psi boiler, looks like a 39psi energy source to the turbine.

The advantage of testing with compressed air is it avoids a host of wet problems. Steam may be far more energetic but it's harder to tame.

Dave

Edited By SillyOldDuffer on 05/09/2020 13:57:15

5 September 2020 at 17:04 #494350Turbine Guy

Participant@turbineguyPosted by SillyOldDuffer on 05/09/2020 13:51:53:Posted by Turbine Guy on 05/09/2020 12:08:22:The advantage of testing with compressed air is it avoids a host of wet problems. Steam may be far more energetic but it's harder to tame.

Hi Dave,

Thanks for your comments. Your last statement really sums up what I have found. If you read through all of this thread and my Testing Models thread you can see all the things I have been surprised with and learned running model engines and turbines on steam. I agree that superheated steam has a lot more energy than the compressed air and in most of my testing the power running on steam has been better than running on air. My small boiler with relatively low output energy exaggerates the moisture problems. I am convinced by what I have seen testing the nozzles unattached to the turbine housing, that the steam available from my smallest boiler is superheated. This boiler does run the tube coming out of the boiler shell over the flame before exiting the cover, so it has a built-in superheater. The steam being invisible exiting the nozzles when they are run without being part of a turbine housing or cover plate shows that the superheater works. I ordered a thermocouple type of temperature sensor and plan to see the actual temperature of the steam supply tube. When I get the temperature sensor, I will find the enthalpy drop of the superheated steam available to the boiler. The enthalpy drop for the estimated 20% moist 20 psig inlet steam and atmospheric exhaust is approximately 50 btu/lb. The enthalpy drop for running my axial turbine on air at 23 psig is approximately 34 btu/lb. The mass flow running on steam from my small boiler is 1.4 lb/hr and running on air from my airbrush compressor is 2.2 lb/hr. The energy available to the turbine after the loss due to condensation for the steam is approximately 21 watts. The energy available to the turbine for the air is approximately 22 watts. This illustrates the magnitude of the loss in available energy for blowing cold air over an uninsulated turbine housing. The wet steam also raises the rotational (windage) losses considerably.

Thanks for your input,

Byron

6 September 2020 at 12:10 #494437SillyOldDuffer

Moderator@sillyolddufferHi Byron,

Your thread is a good example of the type getting lots of reads but few comments. Probably because what you're doing is interesting but specialised. I always read it.

One comment to show I've been paying attention relates to using the rpm of a propeller as a Dynamometer. They work most accurately at high rpm, but become less sensitive at low speeds. It shows on the graph as a long tail where power doesn't increase much over a wide range of low speeds, and then curves up nicely at the high end. There's a high-end limit too due to propeller tips going super-sonic but I don't think it's a problem. But power measured by a propeller at ordinary steam engine speeds won't be accurate in the way it does a good job at turbine rpm.

Ages ago I did a MEW article describing a Dynamometer designed to measure the very low power output of a Ridder's Coffee-cup Stirling engine. I adapted a technique used to measure the power output of 19th century marine engines. Builders of new steamships were contracted to show the engine produced an agreed power output at the propeller (Shaft Horse Power). They couldn't use your method because propellers weren't calibrated as is possible today. Instead, the ship was steamed at contract speed while the torsional twist of the propeller shaft between engine and propeller bearing was measured. The force necessary to twist the shaft as a giant spring had previously been measured in dry-dock with weights and a lever. When cruising the shaft twists slightly between engine and load (the propeller) and this was measured end-to-end with a telescope. SHP can be calculated accurately from rpm and knowing how much force is needed to twist the shaft.

For comparing turbines your calibrated propeller technique is fine I think, but it becomes unreliable when applied to slow engines. For them, safer to use a different type of dynamometer; my torsion shaft can be done with a microcontroller and optical sensors and is adaptable to a wide range of power outputs, but for most model engines I suggest a small conventional brake dynamometer is easier to make and use.

Dave

6 September 2020 at 13:53 #494450Tim Stevens

Participant@timstevens64731My recall of the science involved in air-resistance dynamometers is that the power required to drive a (subsonic) fan etc increases with the cube of the speed (rpm). This relates well to the effort required to shove a vehicle along on a flat road.

As the cube of next to nothing is next to nothing, this explains why the power required at very low speed is itself next to nothing. Any bicyclist will confirm this.

Cheers, Tim

6 September 2020 at 17:46 #494478Turbine Guy

Participant@turbineguyPosted by SillyOldDuffer on 06/09/2020 12:10:14:Your thread is a good example of the type getting lots of reads but few comments. Probably because what you're doing is interesting but specialised. I always read it.

Hi Dave,

I highlighted the section of your post that I found uplifting. I try to show from my testing things to avoid, things that make improvements, and the approximate performance you can expect from model steam engines and steam turbines. I sometimes wonder if anyone cares about these details because I get so few responses. It is nice to know that this is of interest to at least a few people.

I totally agree with your comments on propellers. I should point out more often, that my primary goal with using the propellers is to find if a change makes an improvement. In that respect, If the propeller speed increases or decreases after the change, it shows the change helped or hurt the performance. This should hold true even when the propellers are run at speeds outside their designed and/or tested operating range. You are correct that the actual performance of the propeller should only be used in the speed range it is designed for and/or was tested at.

Hi Tim,

I agree with you that the power of miniature turbines is VERY small at low speeds.

Thanks for the responses,

Byron

6 September 2020 at 20:24 #494495Turbine Guy

Participant@turbineguyPosted by SillyOldDuffer on 06/09/2020 12:10:14:One comment to show I've been paying attention relates to using the rpm of a propeller as a Dynamometer. They work most accurately at high rpm, but become less sensitive at low speeds. It shows on the graph as a long tail where power doesn't increase much over a wide range of low speeds, and then curves up nicely at the high end. There's a high-end limit too due to propeller tips going super-sonic but I don't think it's a problem. But power measured by a propeller at ordinary steam engine speeds won't be accurate in the way it does a good job at turbine rpm.

I thought about the comments you made copied above and went back and looked at some of my charts for the steam engines (especially in my Testing Models thread). I should not have extrapolated the performance based on the APC propellers to speeds below 1000 rpm. Even the APC chart for the 22" diameter propeller I used testing my largest steam engine does not show performance below speeds of 1000 rpm. I am going to copy these comments and add them in a post on my Testing Models thread.

Thanks for pointing this out,

Byron

6 September 2020 at 22:14 #494520Mike Tilby

Participant@miketilby23489Hi Dave

I'd like to look at the article you mentioned in which you describe your shaft torsion dynamometer. Can you please tell me the issue/year of MEW in which it appeared? I am wondering if it would be a more suitable alternative to the water-brake dyno that I have partly built. I am thinking it would enable me to have automated data collection without having to tackle the electronics needed for analysing a load cell. I feel happier about using optical sensors and microcontrollers since I've used them before.

Are there any problems with that type compared to the water brake type? e.g. calibrating the torsion shaft which I guess is done using static weights hanging off of a lever?

I'm not sure, but I think the first torsion dynamometer was the one invented by Charles Parsons in order to investigate lack of power in the Turbinia. His dynamometer is on display here in the Discovery Museum in Newcastle and led to the Denny Brothers of Dumbarton developing the shaft torsion dynamometer for use in the ships they built.

Regards

Mike

6 September 2020 at 23:53 #494530Turbine Guy

Participant@turbineguyThank you all for your responses. I am interested in better ways of testing and appreciate all the ideas that are being presented. I will probably have more to comment on the dynamometers after I do a little research.

Byron

7 September 2020 at 19:51 #494617Turbine Guy

Participant@turbineguyPosted by Turbine Guy on 05/09/2020 17:04:10:Posted by SillyOldDuffer on 05/09/2020 13:51:53:Posted by Turbine Guy on 05/09/2020 12:08:22:I ordered a thermocouple type of temperature sensor and plan to see the actual temperature of the steam supply tube. When I get the temperature sensor, I will find the enthalpy drop of the superheated steam available to the boiler. The enthalpy drop for the estimated 20% moist 20 psig inlet steam and atmospheric exhaust is approximately 50 btu/lb.

I received the thermocouple thermometer. It has two type K thermocouples that can be measured at the same time. To check the calibration of the thermocouples and instrument that reads them, I compared their reading of the ambient temperature with the temperature given by a thermometer we use to measure the outside temperature. Thermocouple 1 showed 77.9 F and Thermocouple 2 showed 80.1 F. Our thermometer and the weather channel gave 79 F, so the calibration was reasonable. I attached the end of thermocouple 1 to the metal outlet tube of my small boiler. I attached the end of thermocouple 2 so that it was in the flow of steam exiting the cover plate nozzle. At near the end of the approximately 11 minute run, thermocouple 1 read 295 F and thermocouple 2 read 227 F. The actual time of the run to boil out ½ cup of water was 11 minutes and 5 seconds. This is very close to the times of the last two runs with this boiler and cover plate. The pressure gage on my small boiler did not work on this test, but the two previous tests were approximately 20 psig. The saturation temperature of the steam at 20 psig is 259 F so the superheat coming out of the boiler was a maximum of 36 F. The superheat in the steam exiting the nozzle was a maximum of 15 F. This test confirmed that I am getting some superheat from my smallest boiler and the mass flow at 20 psig is very consistent at approximately 1.4 lb/hr. This test also showed that it took over 10 minutes to start getting superheat at the nozzle exit. The superheat at the boiler exit started very shortly after the test started and increased very slowly through the length of the test. Assuming the inlet steam tube and the turbine housing were insulated, more of the energy in the steam due to superheating could be recovered. The enthalpy drop for the superheat at the boiler exit to atmospheric pressure is approximately 66 btu/lb. The enthalpy drop from the post of 05/09/2020 (a portion shown above) is 50 btu/lb. The energy available with insulation could be up to 32% higher than leaving the turbine uninsulated. This is a substantial increase in energy even with this relatively low amount of superheat.

Edited By Turbine Guy on 07/09/2020 19:54:18

7 September 2020 at 21:05 #494623SillyOldDuffer

Moderator@sillyolddufferPosted by Mike Tilby on 06/09/2020 22:14:52:Hi Dave

I'd like to look at the article you mentioned in which you describe your shaft torsion dynamometer. Can you please tell me the issue/year of MEW in which it appeared? I am wondering if it would be a more suitable alternative to the water-brake dyno that I have partly built. I am thinking it would enable me to have automated data collection without having to tackle the electronics needed for analysing a load cell. I feel happier about using optical sensors and microcontrollers since I've used them before.

Are there any problems with that type compared to the water brake type? e.g. calibrating the torsion shaft which I guess is done using static weights hanging off of a lever?

I'm not sure, but I think the first torsion dynamometer was the one invented by Charles Parsons in order to investigate lack of power in the Turbinia. His dynamometer is on display here in the Discovery Museum in Newcastle and led to the Denny Brothers of Dumbarton developing the shaft torsion dynamometer for use in the ships they built.

Regards

Mike

Now you're asking. I'm disorganised! I'll have to look through my mags to see if I can find it. Fairly sure it was the first half of 2017 but I might be wrong.

I'll have to check the old book I got the info from: I think it predates Parsons but could be wrong. Calibration as you say by hanging weights on a lever, though that's not necessary if you have the steel's specification.

There's also a mostly complete Arduino project developed in collaboration with Duncan Webster intended for a Dynamometer car he's been working on. The Arduino captures load cell values on each wheel revolution and the time of each revolution. The data is copied to an SD card or streamed to a connected PC. A program on the PC calculates rpm and power etc from the raw data and draws graphs. Been tested with a simulator but not on the track.

Probably the main disadvantage of the torsion type is the long 'spring'. Not as compact as other types. Easy enough to set up and calibrate though. The Arduino and photosensors measure the angular twist by detecting the time difference between two normally aligned holes in discs at each end other spring. The disc next to the load lags behind the one at the engine end.

Dave

9 September 2020 at 13:45 #494875Mike Tilby

Participant@miketilby23489Posted by SillyOldDuffer on 07/09/2020 21:05:33:Now you're asking. I'm disorganised! I'll have to look through my mags to see if I can find it. Fairly sure it was the first half of 2017 but I might be wrong.

I'll have to check the old book I got the info from: I think it predates Parsons but could be wrong. Calibration as you say by hanging weights on a lever, though that's not necessary if you have the steel's specification.

There's also a mostly complete Arduino project developed in collaboration with Duncan Webster intended for a Dynamometer car he's been working on.

Probably the main disadvantage of the torsion type is the long 'spring'.

Dave

Thanks Dave.

On thinking about the torsion type dyno I am not sure how I would easily measure the angular twist accurately when the shaft is stationary – while keeping the loaded lever dead horizontal. Maybe with a dividing head to hold and rotate one end of the rod while the weighted lever is attached to the other end?? A finely divided rotary encoder disc might do the job but would add complexity. These thoughts together with what you say about the length of the shaft make me think that the load-cell approach might not be so bad after all. Nevertheless I'd still be very interested to read your article. I looked for an index to MEW but the only one I can find does not cover anything more recent than 2016.

I'll ask Duncan about the dynamometer car.

I'd be interested to hear if you find that book. Parsons designed his dynamometer very soon after the first trials of Turbinia had been carried out in 1894.

Regards

Mike

9 September 2020 at 16:29 #494914SillyOldDuffer

Moderator@sillyolddufferPosted by Mike Tilby on 09/09/2020 13:45:08:Posted by SillyOldDuffer on 07/09/2020 21:05:33:…

…

On thinking about the torsion type dyno I am not sure how I would easily measure the angular twist accurately when the shaft is stationary – while keeping the loaded lever dead horizontal. …. Nevertheless I'd still be very interested to read your article. I looked for an index to MEW but the only one I can find does not cover anything more recent than 2016.

I'd be interested to hear if you find that book. Parsons designed his dynamometer very soon after the first trials of Turbinia had been carried out in 1894.

Regards

Mike

Can't find the magazine or the book, which I'm sure is much later than 1894 so Parsons is the man. Talented chap!

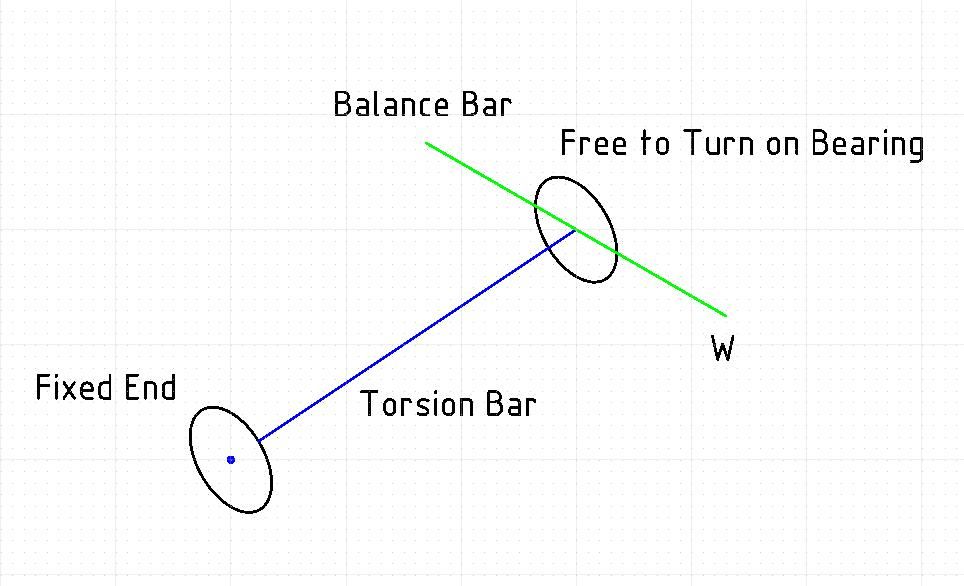

Anyway this diagram shows how I measured the elasticity of the torsion bar (a length of piano wire):

One end of the bar is clamped while the other terminates in a free to rotate disc. A balance bar is glued to the disc and adjusted so the torsion bar is unstressed, ie the two ends of the balance bar are at equal height. Then weights are added at point W causing the torsion bar to twist and the balance bar to dip. The angle can be measured directly with a home-made protractor, but I calculated it with trigonometry.

It gives the elasticity of the spring, from which the force needed to deflect through a measured angle can be calculated. From unreliable memory I think the torsion bar must be at least 40 times longer than its diameter.

Still looking for the magazine. As I can't find any mags containing my articles, I must have put them in a safe place and forgotten where it is.

Dave

9 September 2020 at 17:57 #494932Mike Tilby

Participant@miketilby23489Thanks for that – I see I was making things much too complicated. I guess you used trigonometry to calculate the the reduced torque as the arm with the weight dipped down below horizontal – in addition to calculating the actual angle.

I think I've identified the issue that your article appeared in – by looking at images of mag. covers. The issue for June 2017 (No 255) has a list of 5 projects for the workshop, one of which was "Arduino dynamometer". Does that sound like the one? If so I'll buy a copy.

Mike

10 September 2020 at 17:00 #495105Turbine Guy

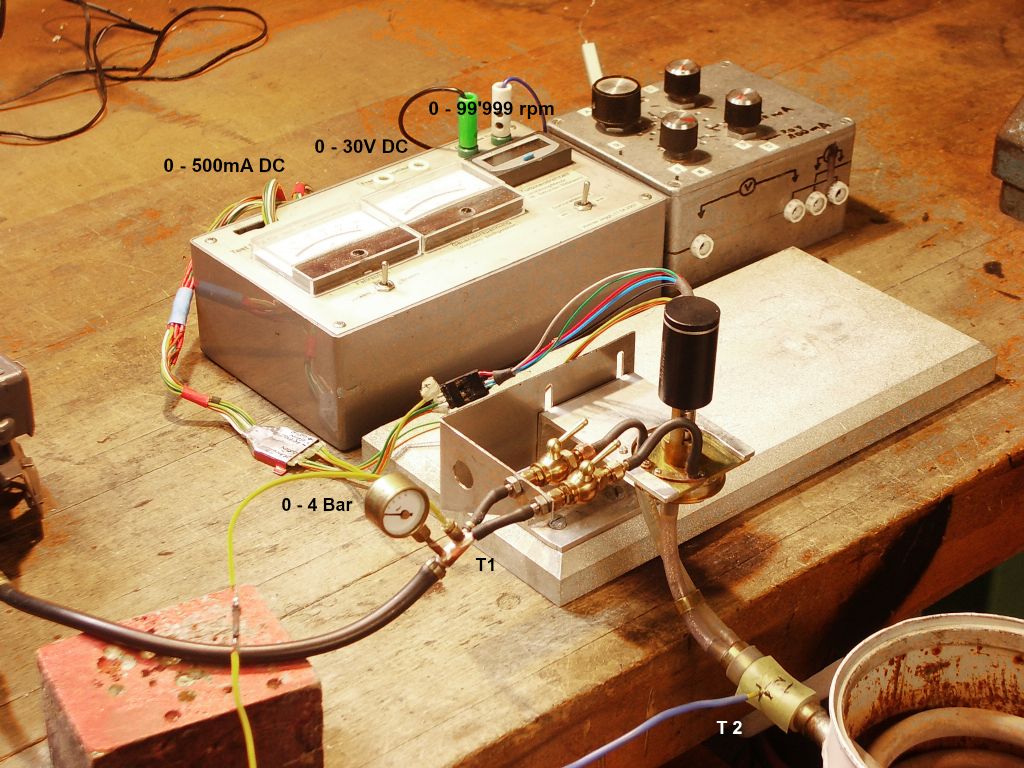

Participant@turbineguyWerner Jeggli shows in the post of 18/06/2019 the picture of the system he uses to measure the power of his steam turbines. He uses the brushless DC servomotor as a generator and can change the resistance to alter the load on the turbine. This allows him to run the turbine at any speed and measure the maximum power at that speed. This is the biggest short coming of using propellers for a load. The torque of the turbine determines the speed it can spin the propeller. What makes this even worse, is the very small number of propellers available with test data showing their performance at low powers and high speeds. Because of this and his distrust of extrapolating results, Werner has described my method of testing as “woefully inadequate”. I believe that if you are primarily interested in finding the maximum performance at a particulate speed or range of speeds, you do need a much more sophisticated test method. Either Werner’s method or the use of a torsion type of dynamometer would substantially improve the testing. I do believe that using the performance of a propeller given at a speed within a tested speed range is valid and if it meets your needs, is far simpler and less costly.

Edited By Turbine Guy on 10/09/2020 17:03:19

Edited By Turbine Guy on 10/09/2020 17:08:43

Edited By Turbine Guy on 10/09/2020 17:11:49

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Stationary engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Diving in to ATC?

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 4

- 12

-

21 July 2025 at 21:32

Steve355

-

Woodward/Wilding Gearless clock

Started by:

smf in: Clocks and Scientific Instruments

- 3

- 3

-

21 July 2025 at 21:30

Chris Raynerd 2

-

Adding a quill lock to a drill press

Started by:

beeza650 in: Manual machine tools

- 4

- 9

-

21 July 2025 at 21:15

not done it yet

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 6

- 19

-

21 July 2025 at 21:14

grubscrew

-

Redwing Cylinder head

Started by:

Durhambuilder in: I/C Engines

- 3

- 5

-

21 July 2025 at 21:07

grubscrew

-

Pipe bending by hand versus pipe bending tools

Started by:

Greensands in: Workshop Tools and Tooling

- 3

- 3

-

21 July 2025 at 21:06

bernard towers

-

Arc Euro Trade Ltd.

Started by:

Ketan Swali in: General Questions

- 20

- 20

-

21 July 2025 at 21:03

KEITH BEAUMONT

KEITH BEAUMONT

-

Lidl castors

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 6

- 7

-

21 July 2025 at 21:00

bernard towers

-

Amadeal lathes – Any good??

1

2

Started by:

Tim Sallows in: Workshop Tools and Tooling

- 16

- 29

-

21 July 2025 at 19:16

JasonB

JasonB

-

Issue 4767 and links

Started by:

Andy Stopford in: Model Engineer & Workshop

- 2

- 2

-

21 July 2025 at 19:14

JasonB

JasonB

-

Round Bar Bender

Started by:

Trevor Howley in: Workshop Tools and Tooling

- 1

- 1

-

21 July 2025 at 18:46

Trevor Howley

-

My vise isn’t at 90 degrees

Started by:

moonman in: Beginners questions

- 15

- 24

-

21 July 2025 at 15:41

JasonB

JasonB

-

5 inch gauge Stirling single

Started by:

Michael Callaghan in: Locomotives

- 5

- 7

-

21 July 2025 at 15:37

Michael Callaghan

-

Hopeless…Alibre Ass

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 6

- 21

-

21 July 2025 at 14:40

blowlamp

-

Edward Thomas excessive wheel slip

Started by:

Ian R in: Locomotives

- 3

- 4

-

21 July 2025 at 14:11

Ian R

-

Hofmann Rollers

Started by:

Martin Kyte in: General Questions

- 11

- 18

-

21 July 2025 at 13:07

DC31k

-

Herbert B drill information?

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 4

- 12

-

21 July 2025 at 12:45

Michael Gilligan

Michael Gilligan

-

What’s in the archive?

Started by:

Michael Callaghan in: General Questions

- 2

- 3

-

21 July 2025 at 12:36

Michael Callaghan

-

Myford S7 VFD problem

1

2

Started by:

Glyn Davies in: Manual machine tools

- 21

- 38

-

21 July 2025 at 10:36

Glyn Davies

-

Model Engineer Magazine Collection

Started by:

mfengine1 in: Books

- 9

- 12

-

21 July 2025 at 09:22

Norman Blackburn 1

-

Panorama : Fighting Cyber Criminals

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 2

- 2

-

21 July 2025 at 09:20

Nigel Graham 2

-

What Did You Do Today 2025

1

2

…

8

9

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 202

-

20 July 2025 at 21:39

Dalboy

-

Polishing compounds for stainless steel (mild abrasives))

Started by:

Simon Williams 3 in: Beginners questions

- 13

- 14

-

20 July 2025 at 20:02

Russell Eberhardt

Russell Eberhardt

-

Bad design, or am I missing something?

Started by:

half whit in: Beginners questions

- 5

- 7

-

20 July 2025 at 19:16

Julie Ann

Julie Ann

-

Mistry dividing attachment

1

2

Started by:

Brian Merrifield in: Workshop Tools and Tooling

- 17

- 42

-

20 July 2025 at 18:43

Tony Jeffree

Tony Jeffree

-

Diving in to ATC?

-