Model Turbines

Model Turbines

Home › Forums › Stationary engines › Model Turbines

- This topic has 605 replies, 28 voices, and was last updated 9 June 2025 at 15:11 by

Turbine Guy.

-

AuthorPosts

-

16 August 2023 at 19:09 #656783

Werner Jeggli

Participant@wernerjeggli14222Hello Byron,

Your proposed oil obviously is designed for ambient temperature, for a short sterilisation at 100°C at most, A model steam turbine is supposed to operate at steam of say 4 Bar. The wet steam temperature at this pressure will be 151°C. Your tests therefore should be run with live steam!

I cannot find any information in fhe internet about the temperature behaviour of this proposed oil. I therefore will stick to my well proven Krytox 105.

regards Werner

17 August 2023 at 11:55 #656858Turbine Guy

Participant@turbineguyHi Werner,

You are right, the Syntek oil is only suitable for air. I have used the Krytox 105 oil for steam ever since you suggested it, and it has worked very well for me.

Hope you are doing well,

Byron

17 August 2023 at 19:18 #656903Turbine Guy

Participant@turbineguyThe 12/03/2020 Post was where I mentioned that Werner had suggested using the Krytox GPL 105 oil for running on steam. Following posts show what I experienced using this oil with steam and with air. The AeroShell Fluid 12 that came with the ball bearings I was using at that time worked well on air but was not available to me in small quantities. Anyway, there is a lot of discussion about using various oils starting with that post and reading the following posts.

19 August 2023 at 19:39 #657155Turbine Guy

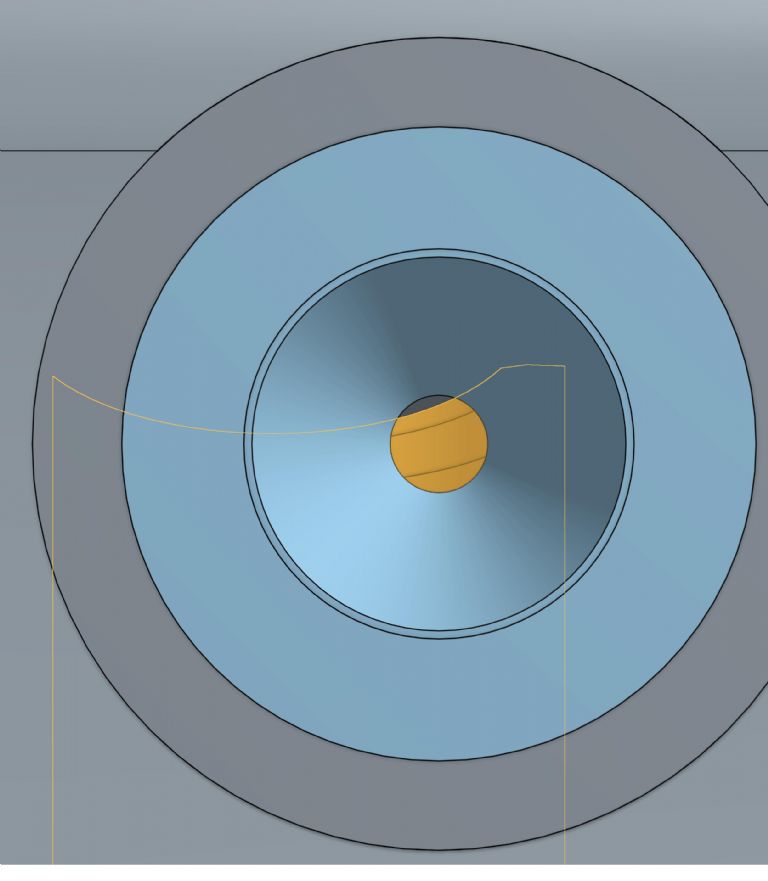

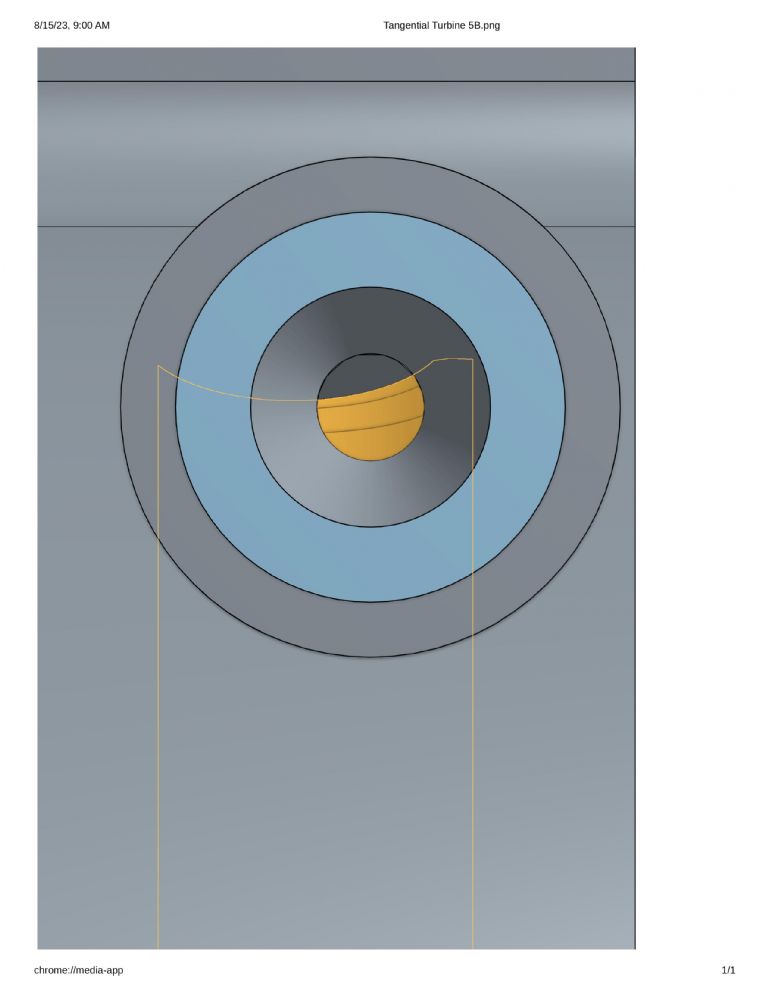

Participant@turbineguyI have been curious why the rotor velocity coefficient found for Tangential Turbine 5B is so much lower than the rotor velocity coefficient found for Tangential Turbine 5C even though they were determined using the same methods described in the posts starting with 23/03/2023 Post. The rotor velocity coefficient found in these posts for Tangential Turbine 5B was 0.27. Using the same methods for Tangential Turbine 5C starting with the 31/03/2023 Post, the rotor velocity coefficient was found to be 0.51. This is a very big difference for the same rotor. Only the nozzles are different for these turbines. Tangential Turbine 5B had a nozzle size of 0.041” (1.00mm) and Tangential Turbine 5C had a nozzle size of 0.024” (0.61mm). I think that the leakage by the rotor due to the concave shape of the edge of the pockets is causing the problem. I tried various section views to show this, but the following images of the solid models of these turbines illustrate it best. The views are looking through the nozzles at the rotor that is highlighted in an orange color. The first image is the smaller nozzle and you can see that there is very little opening not covered by the rotor. The second image is the larger nozzle and approximately ⅓ of the nozzle is not covered by the rotor. It is probably the flow loss that is causing the large reduction in rotor velocity coefficient with the large nozzle. The flow exiting the nozzle deflects toward the rotor from 1 to 6 degrees according to my sources of information. This would probably be enough to almost eliminate the flow loss for the smaller nozzle but the larger nozzle would still have quite a high mass flow escape.

Edited By Turbine Guy on 19/08/2023 19:48:09

23 September 2023 at 16:22 #661197Turbine Guy

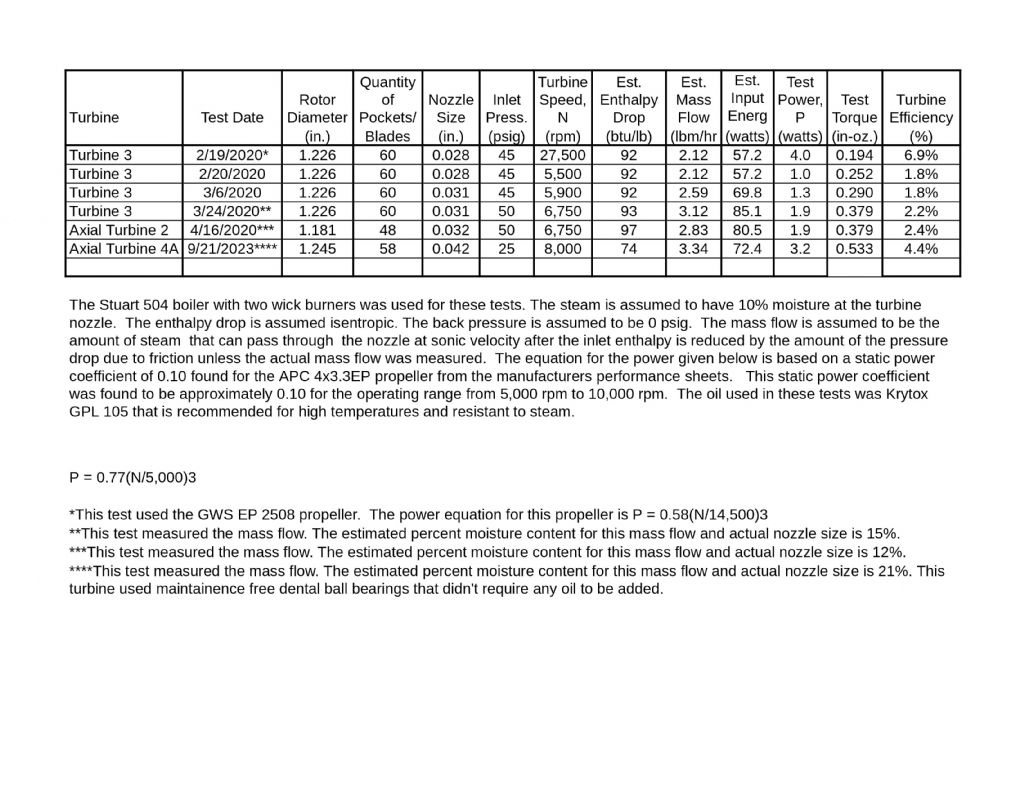

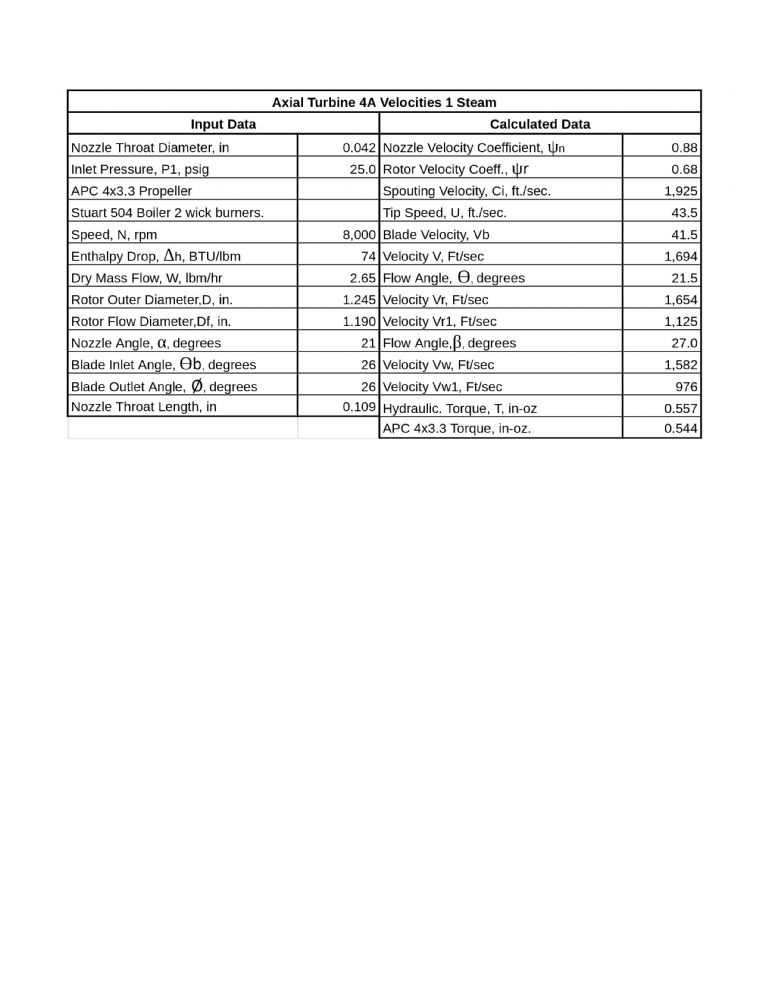

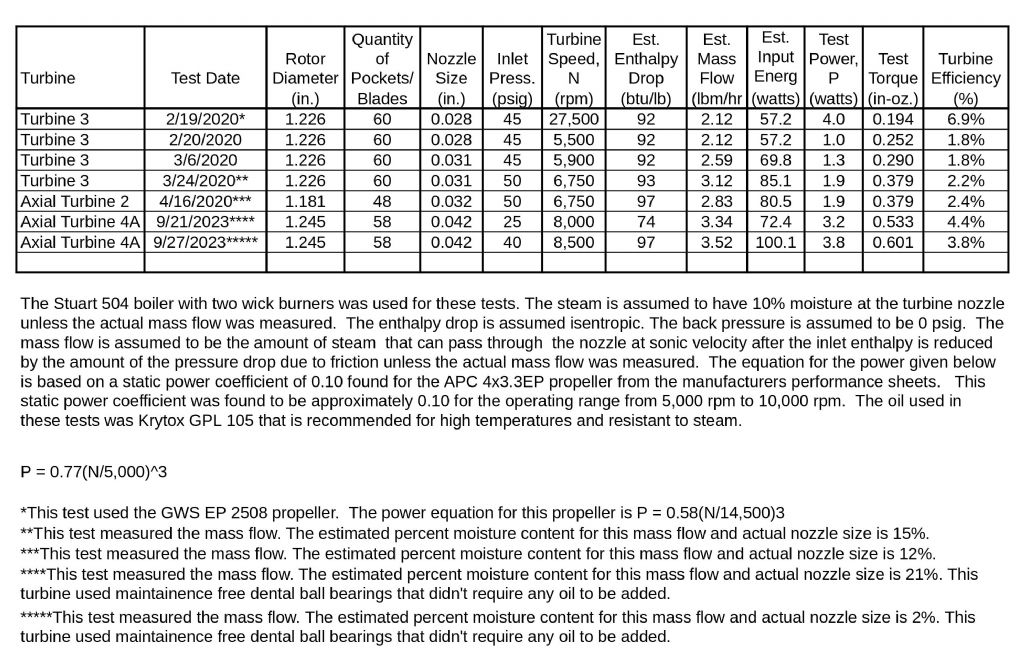

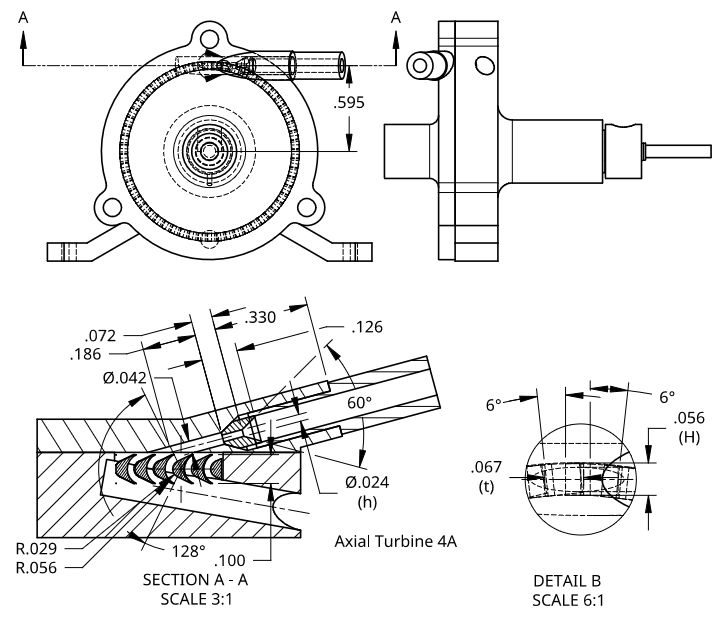

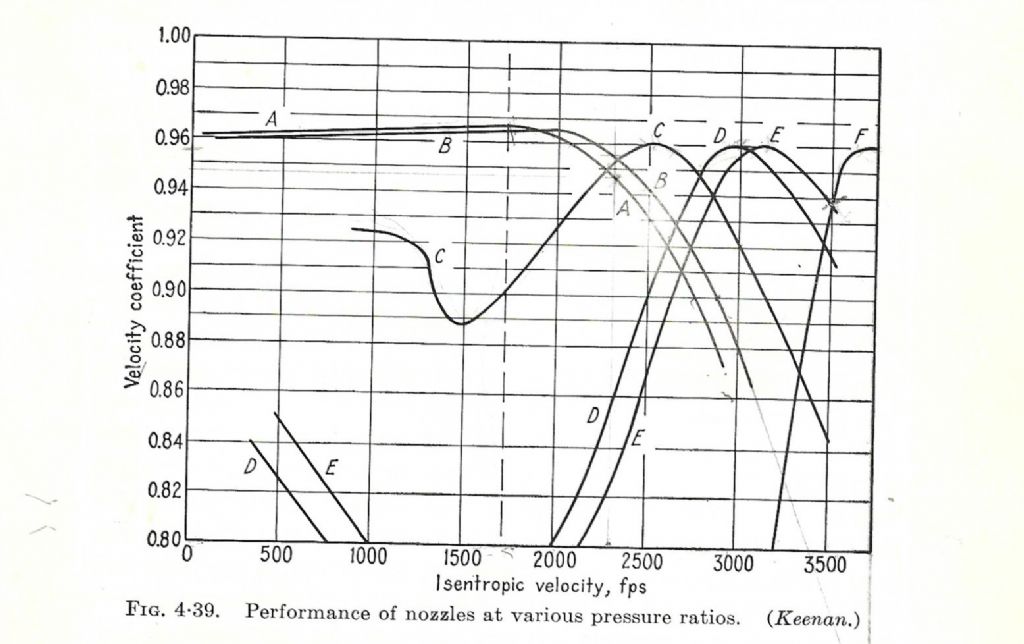

Participant@turbineguyI have done very little testing of Axial Turbine 4A on steam, so I ran a test yesterday on steam using my Stuart 504 boiler. I used the APC 4×3.3 propeller since it is the smallest propeller I have that is not overpowered by this boiler. I added the results of this test to the test sheet shown in the 26/05/2021 Post. I stated in that post that the torque shown for the other turbines appeared to be too high. The test with Axial Turbine 4A found a torque even larger than these turbines by an amount that appears to be consistent with the higher efficiency of this turbine and indicates the torques shown in this table appear to be correct. I made the Velocity 1 spreadsheet for Axial Turbine 4A running on steam shown below. The mach number, pressure drop due to friction in the nozzle, and clearance were lower with steam than with air so I recalculated the nozzle velocity coefficient. I estimated the nozzle velocity coefficient of Axial Turbine 4A to be approximately 0.88. This velocity coefficient was determined by starting with the velocity coefficient of 0.93 for the conical nozzle as explained in the 29/03/2023 Post then finding the reduction for the pressure drop due to friction. The reduction due to pressure drop was 0.98. This reduced the nozzle velocity coefficient to 0.91. I then found the reduction for expanding to supersonic velocities with a converging only nozzle shown in the diagram in the 29/03/2023 post as line A. The Mach number for Axial Turbine 4A was 1.3 and the reduction for expanding supersonic is approximately 0.98. This reduces the nozzle velocity coefficient to 0.89. The last reduction was for the distance between the nozzle outlet to the rotor. This was 0.010” for Axial Turbine 4A and the correction is 0.99 for this distance. This reduces the nozzle velocity coefficient to 0.88. I kept the same rotor velocity coefficient used for Axial Turbine 4A in all the other velocity spreadsheets and once again the estimated torque was quite close to the actual test torque.

28 September 2023 at 17:15 #661930Turbine Guy

Participant@turbineguyI made another steam test with Axial Turbine 4A and the Stuart 504 boiler and added it to the test sheet shown in the last post. I did two things differently with this test. I installed the wick burners on the opposite end of the boiler and closed the opening on the other end. This forced the flame to move down the entire length of the boiler before going out the exhaust. The single wick burner that originally came with the Stuart 504 boiler was much longer than the two wick burners that replaced it after it started to leak. I also slowly opened the valve on the boiler keeping the pressure at 40 psig (2.7 bar) until the turbine got hot enough to maintain this pressure with the throttle almost fully open. This raised the energy level in the steam quite a bit resulting in the steam being almost completely dry. The net result was the power increased only slightly higher than the last test even though the energy level was higher and the steam was drier. This was caused by no space for the steam to expand to a higher Mach number before contacting the rotor. Running on air at very low pressure the velocity exiting the nozzle was almost sonic and the maximum efficiency occurred keeping the clearance on each face of the rotor very small. Werner Jeggli used a thick gasket to get the space needed for the steam to expand to a higher Mach number and that is what I will try next.

30 October 2023 at 17:59 #685082

30 October 2023 at 17:59 #685082Turbine Guy

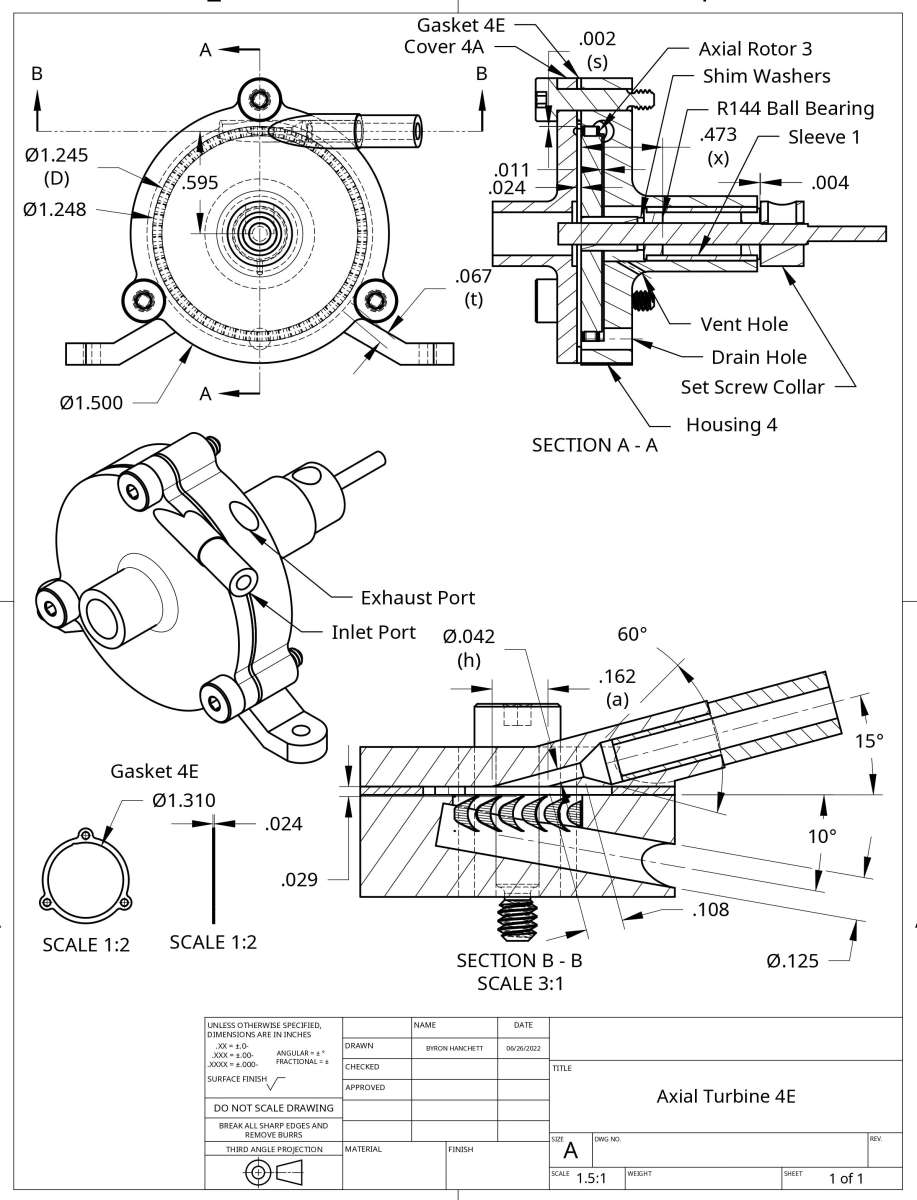

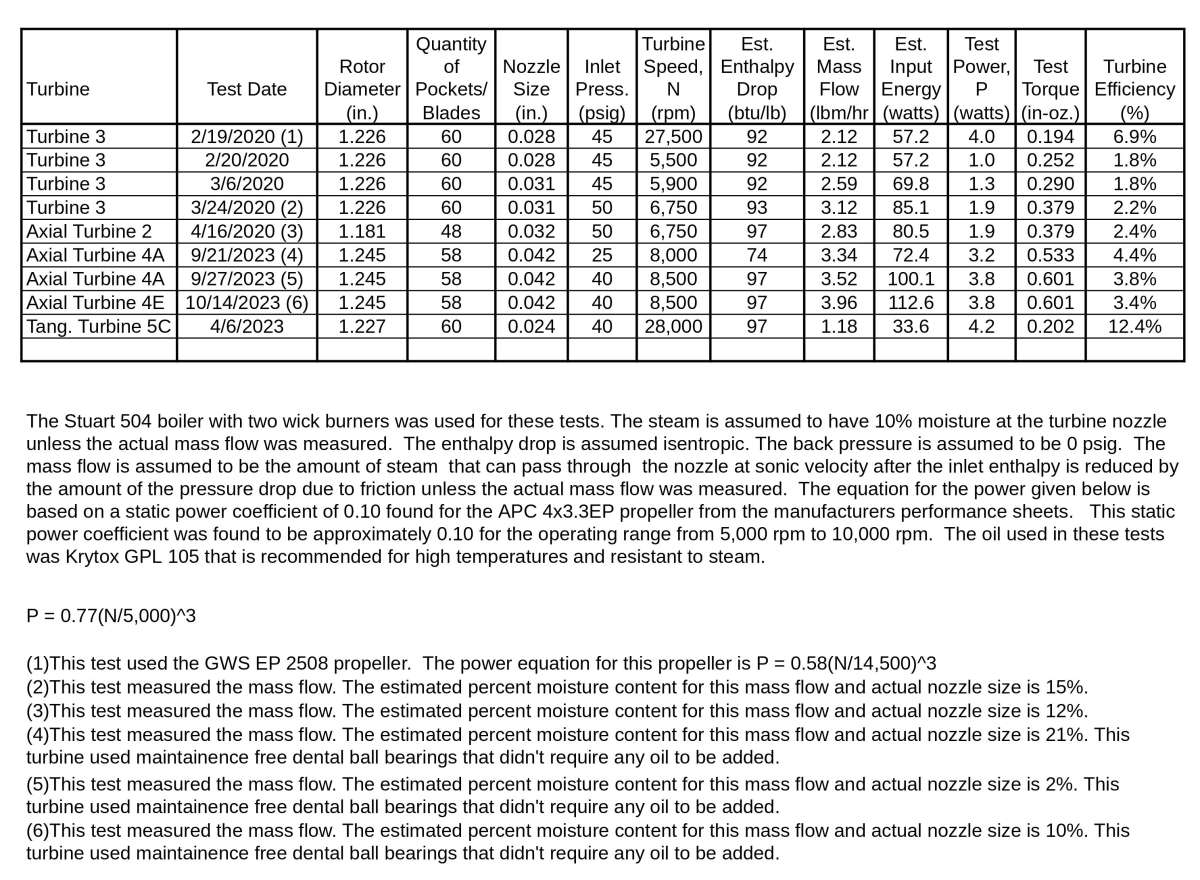

Participant@turbineguyI made a test of Axial Turbine 4E that is the same as Axial Turbine 4A but with a gasket as shown on the following drawing with the test results shown in the following table. The gasket made almost no difference in performance probably because the steam was only slightly supersonic and whatever gain in performance from giving the steam space to expand was offset by the increased leakage area. I did tests with air with the same results.

31 October 2023 at 19:15 #685463

31 October 2023 at 19:15 #685463Turbine Guy

Participant@turbineguyI added the test results shown in the 7 April 2023 post to the table shown in the last post to show the improvement of the last Tangential Turbine and illustrate the effect of running at higher turbine speeds. The 28,000 rpm speed results in a rotor tip velocity (U) to spouting velocity (Co) ratio (U/Co) value of 0.07 that even the best turbines would not exceed 20% efficiency as shown in the following graph. The tests using the larger propeller had maximum U/Co values of less than 0.02 so even the best turbines would have efficiencies under 10%.

3 November 2023 at 18:41 #686459

3 November 2023 at 18:41 #686459Turbine Guy

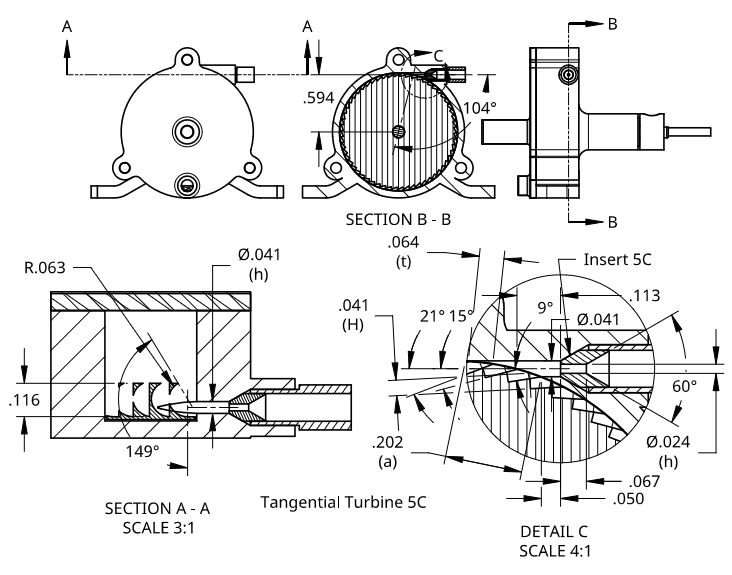

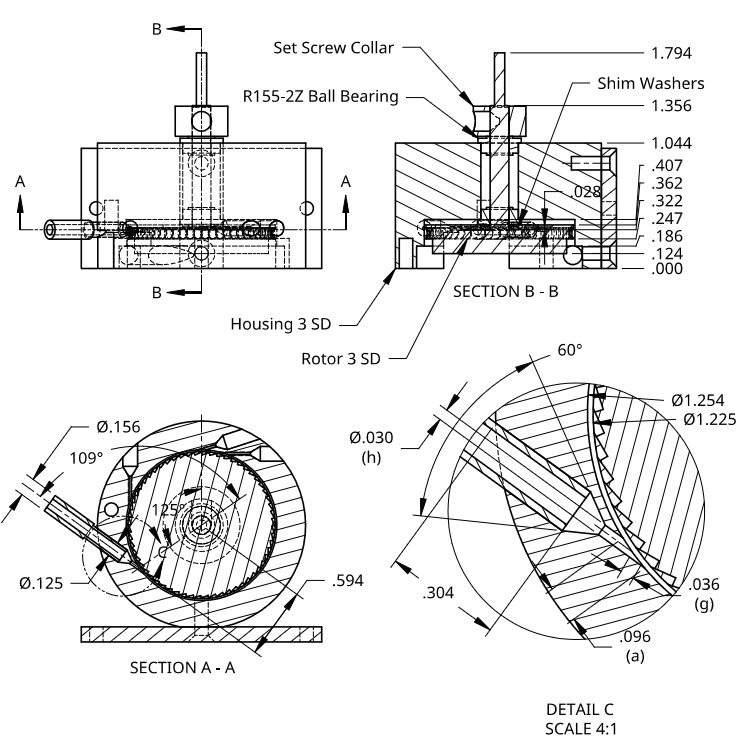

Participant@turbineguyThe following test sheet shows the performance of Axial Turbine 4D and Tangential Turbine 5C running on air I said I was going to show after the 27/03/2023 post that also included the following drawings. I will look at the reasons for this performance in the next posts.

I took a second look at the way the nozzle velocity coefficients were found

I estimated the nozzle velocity coefficient of Axial Turbine 4D to be approximately 0.69 and 0.73 for Tangential Turbine 5C for the tests shown in the last post. These velocity coefficients were determined by starting with the velocity coefficient of 0.93 for the conical nozzle as explained in the 17/03/2023 post then finding the reduction for the pressure drop due to friction. The reduction due to pressure drop was 0.94 for both turbines since they had the same nozzle throat length. This reduced the nozzle velocity coefficient to 0.87. I then found the reduction for expanding to supersonic velocities with a converging only nozzle shown in the following diagram as line A. In the tests shown in the previous post, the Mach number for Axial Turbine 4D was 1.47 and for Tangential Turbine 5C was 1.43. The reduction for expanding supersonic is approximately 0.97 for both turbines when rounded to two decimal places. This reduces the nozzle velocity coefficient to 0.84 for both turbines. The last reduction was for the distance between the nozzle outlet to the rotor. This was 0.186” for Axial Turbine 4D and 0.113” for Tangential Turbine 5C as shown on the two drawings of the last post. The reduction in nozzle velocity coefficient for this was 0.82 for Axial Turbine 4D and 0.87 for Tangential Turbine 5C. This reduced the nozzle velocity coefficient to 0.69 for Axial Turbine 4D and to .73 for Tangential Turbine 5C as stated at the first of this post. The reduction in rotor velocity coefficient for supersonic velocity was 0.98 for both turbines. The rotor velocity coefficient found from the static torque test explained in the 23/03/2023 post were 0.68 for Axial Turbine 4A and 0.27 for Tangential Turbine 5B. Neither of these turbines had the insert and the discharge velocity of the nozzles were approximately sonic, so using the correction for supersonic velocities reduces the rotor velocity coefficient to 0.67 for Axial Turbine 4D and to 0.26 for Tangential Turbine 5C. I will show in the next post how the test results in the last post compare with the velocity diagrams like shown in the 23/03/2023 post.

Edited By Turbine Guy on 29/03/2023 21:20:09I looked at the way I determined the nozzle velocity coefficients in this post and believe the corrections I made for the distance from the nozzle outlet to the rotor are not correct. I believe the methods used for the other corrections are valid and the corrected value for the nozzle velocity coefficient of 0.84 for both turbines should be used. The distance from the nozzle outlet to the rotor is space needed for the gas to expand to supersonic Velocities. I will try to find the distance required for the gas to expand to supersonic velocities and the effect of having too short or too long of a distance.

4 November 2023 at 06:41 #686508 Michael GilliganParticipant@michaelgilligan61133

Michael GilliganParticipant@michaelgilligan61133Good to see that your ongoing masterwork appears to have been successfully migrated to the new forum.

MichaelG.

4 November 2023 at 18:20 #686895Turbine Guy

Participant@turbineguyThanks for the kind remarks Michael. The way we add and search is different but we can still do many of the things we were able to do before the change.

I am going to add the posts made 24 May 2021 that show the effect of the space for the gas to expand as discussed in the 3 November 2023 post. This was done for Tangential Turbine 3 SD Gap and the drawing included in these posts showed the dimensions of this Turbine when the tests were made.

4 November 2023 at 18:22 #686896Turbine Guy

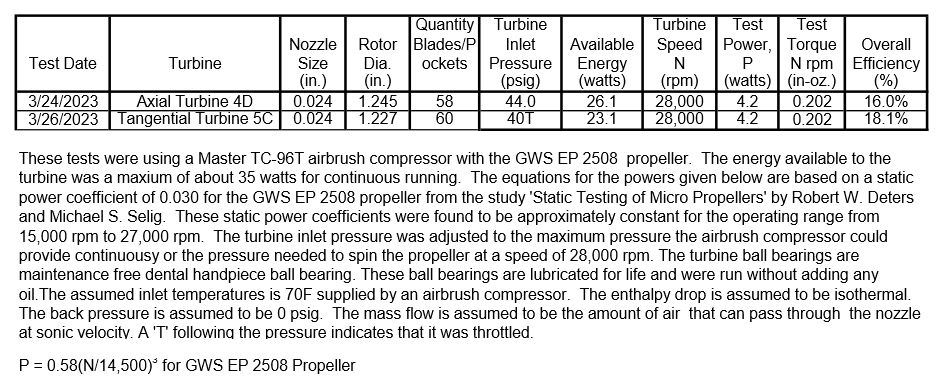

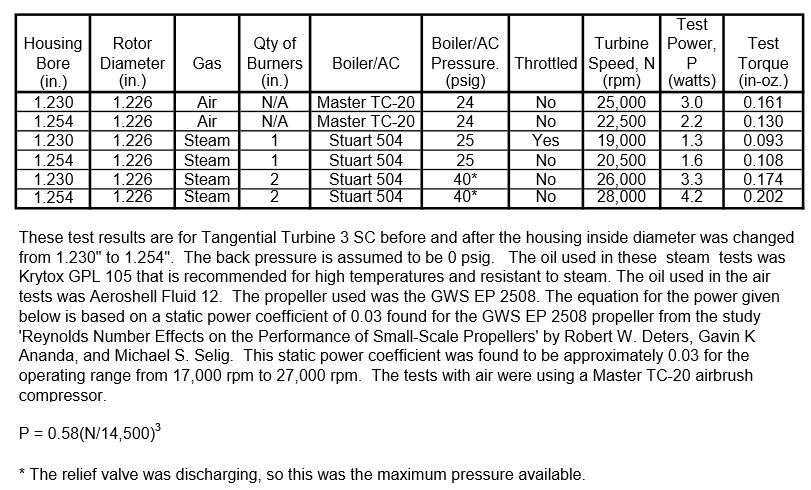

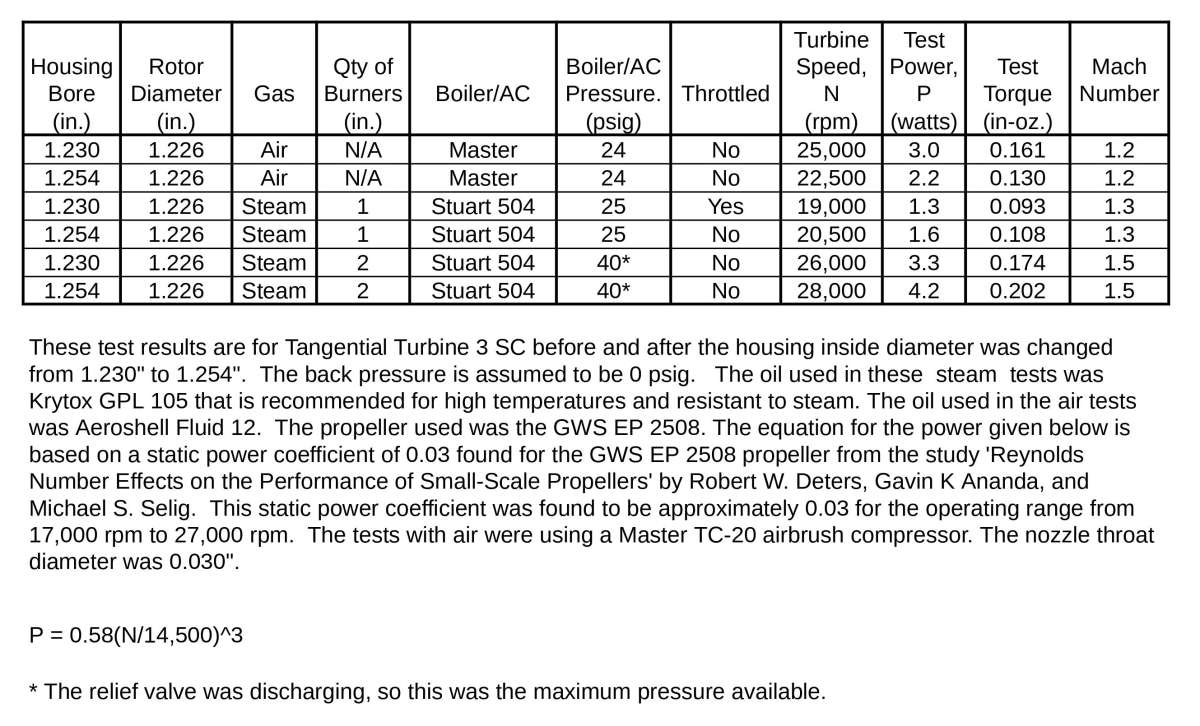

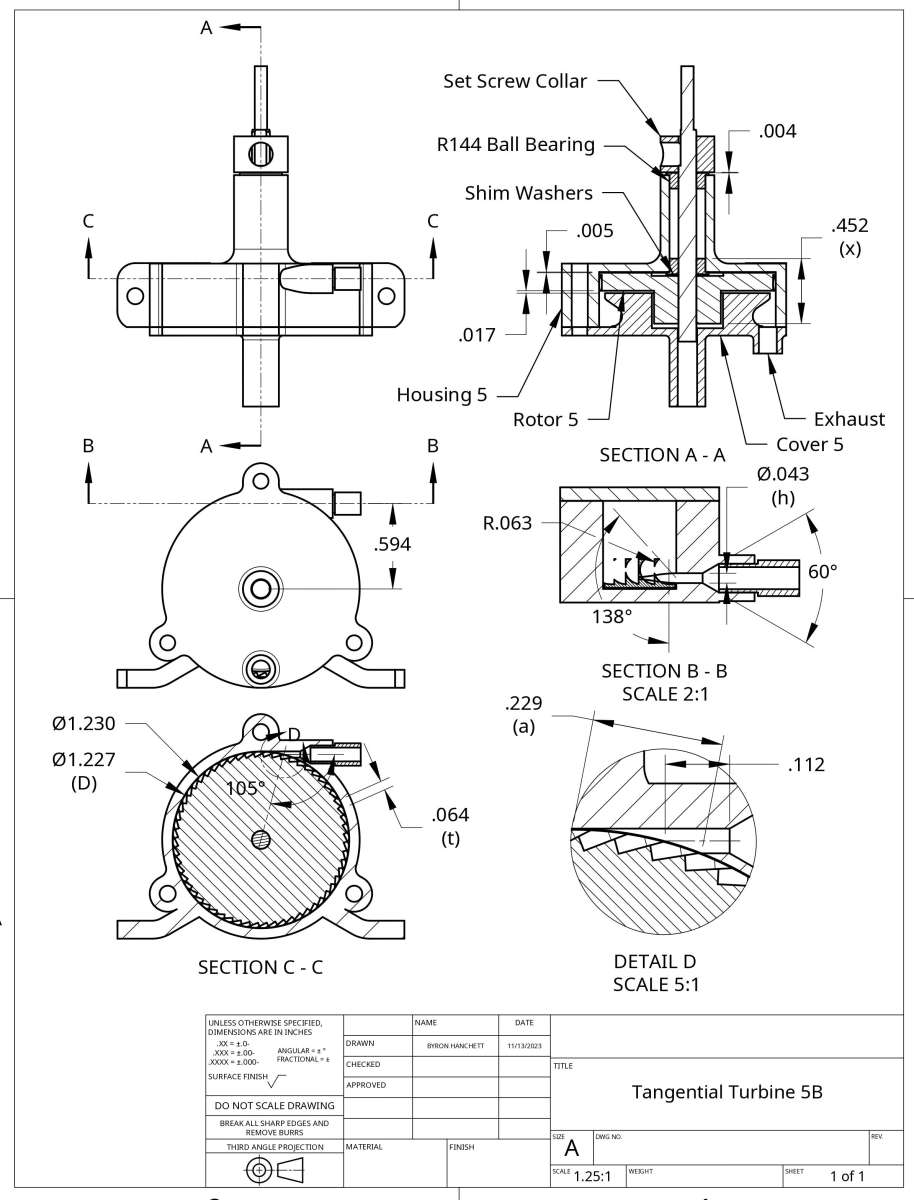

Participant@turbineguyI decided to go ahead and try enlarging the housing diameter that the rotor fits under in Tangential Turbine 3 SD. The following drawing is an update to the drawing shown in the 27/09/2020 Post. I increased the diameter from 1.230” to 1.254” to provide a space for the gas exiting the nozzle to expand before contacting the rotor. The dimension 0.036” (g) is the minimum distance the gas travels before contacting the rotor. I thought that opening this gap for the higher energy flows would reduce the power for lower energy flows. I ran several tests before opening the gap and compared the results with those after opening the gap. The next post will show the table I created to compare the results.

4 November 2023 at 18:28 #686898Turbine Guy

Participant@turbineguyThe following table shows the results of the testing I described in the previous post. The power decreased 0.8 watts running on air at 24 psig from my airbrush compressor. This is the lowest input energy and needs the smallest gap. The power increased 0.3 watts running on steam from the Stuart 504 boiler with 1 burner. This is a slightly higher level of input energy and requires a little more gap. The power increased 0.9 watts running on steam from the Stuart 504 boiler with 2 burners. These tests indicate that if you plan to run on a low energy source like a airbrush compressor the gap should be kept small. If you plan on running on steam the gap of 0.036” would be right for pressures up to 50 psig. These results are using a convergent only nozzle with a throat diameter of 0.030”.

I will add a revised table in the next post showing the Mach number for these pressures and some additional comments.

4 November 2023 at 19:25 #686902Turbine Guy

Participant@turbineguyThe following table adds the Mach number to the table shown in the last post. This shows the importance of the space for the gas to expand when using a converging only nozzle for higher Mach numbers. Werner Jeggli uses a gap between the nozzle outlet and rotor face of 0.8mm for steam pressures up to 4 Bar (60 psig) at the Turbine entrance.

15 November 2023 at 16:45 #690891

15 November 2023 at 16:45 #690891Turbine Guy

Participant@turbineguyI ran tests of Axial Turbine 4A and Tangential Turbine 5B without a propeller (no load) to find the rotational losses at a speed of 28,000 rpm. It required a turbine inlet pressure of approximately 2.0 psig to reach this speed with Axial Turbine 4A and a pressure of approximately 1.5 psig to reach this speed with Tangential Turbine 5B. The power available to the turbines with these pressures were approximately 1.5 watts for Axial Turbine 4A and approximately 1.1 watts for Tangential Turbine 5B. The rotational loss at 28,000 rpm was approximately 0.4 watts higher for Axial Turbine 4A than for Tangential Turbine 5B. Since both of these turbines use the same bearings and have been operated about the same amount of time, the difference in power required was probably due to higher windage loss for Axial Turbine 4A.

This completes all the tests I currently plan to do with these turbines unless someone would like me to run another test to show something I have missed. The preceding posts show the things I’ve tried and the tests made to develop these turbines to this level. The following drawings show the existing dimensions and positions of the parts for these turbines.

17 November 2023 at 15:17 #691622

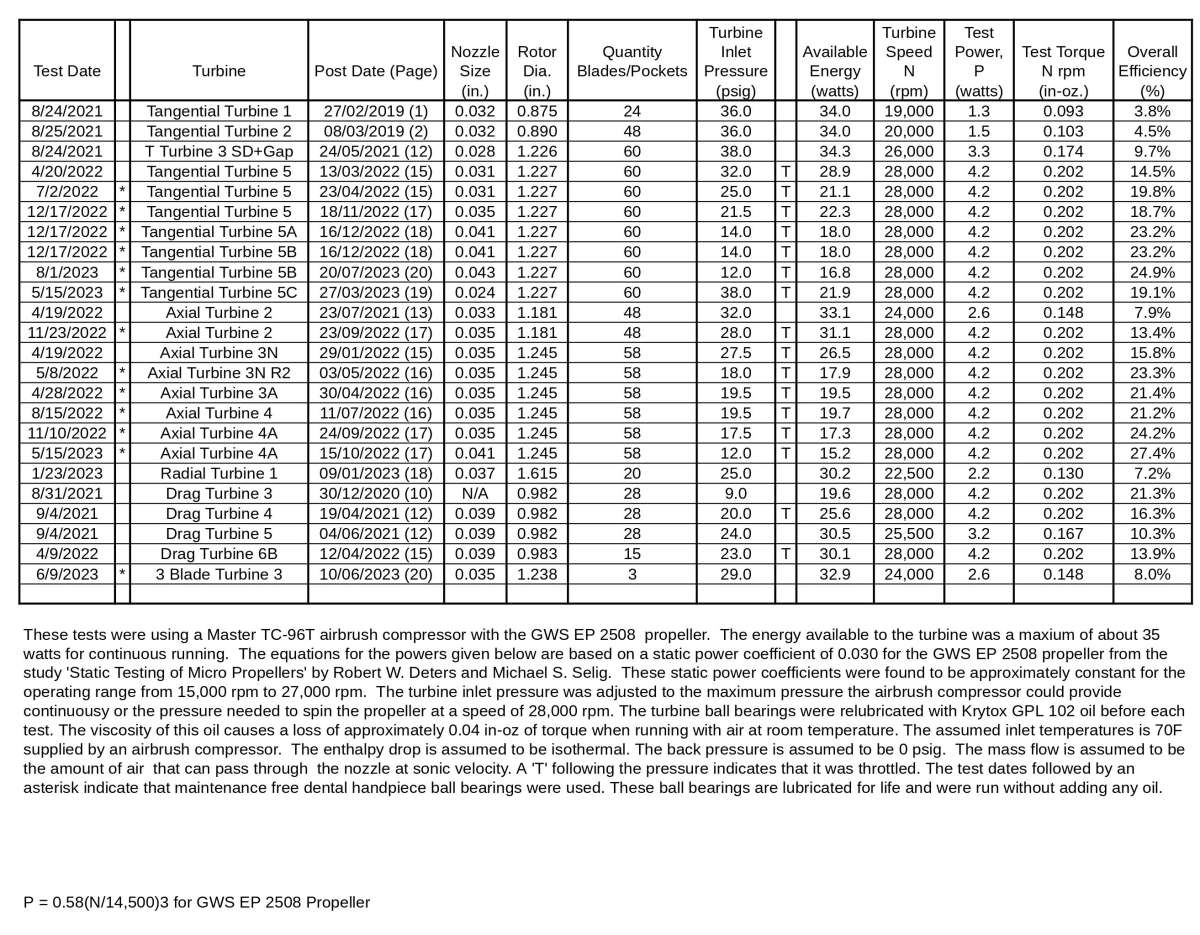

17 November 2023 at 15:17 #691622Turbine Guy

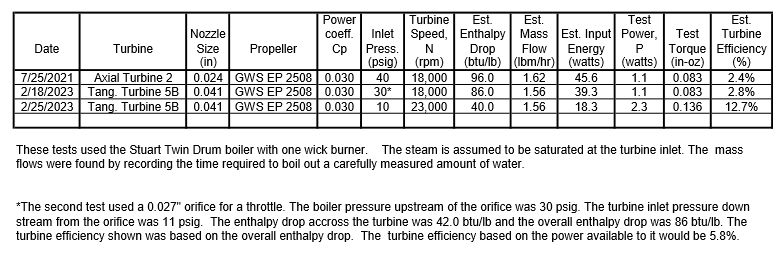

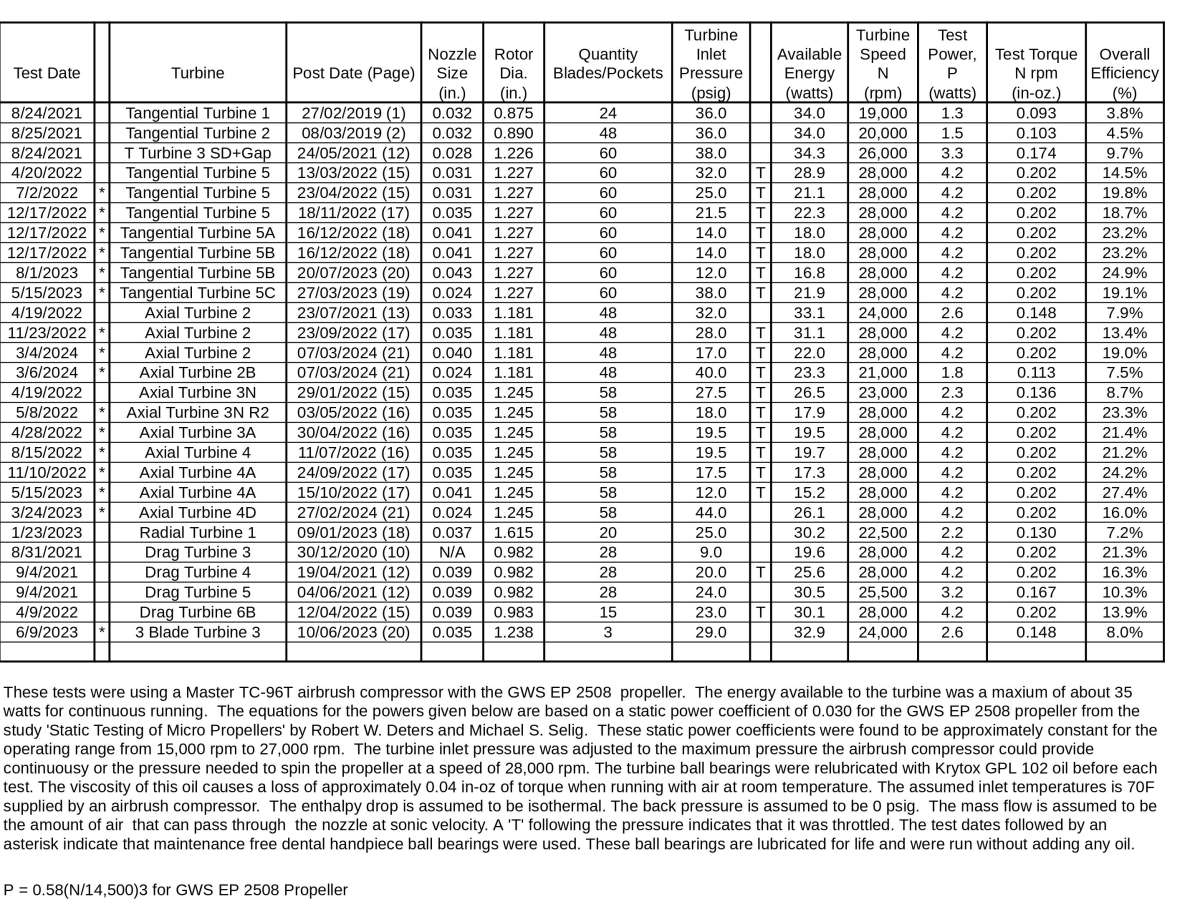

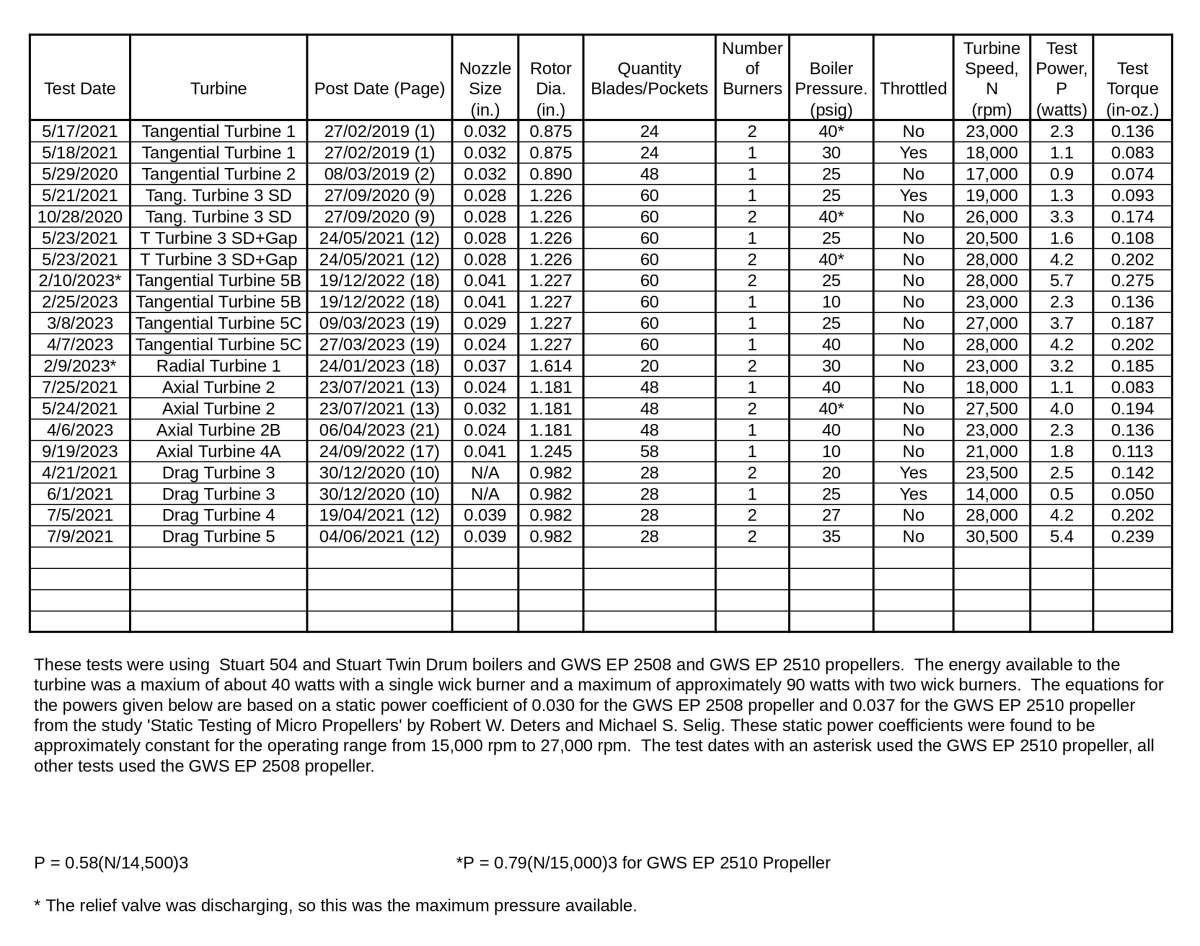

Participant@turbineguyThe following test sheet shows the tests I’ve made with my turbines. Since this thread has run for several years and is up to 21 pages, I added a column showing the post date and page number for the post describing the turbine used in the test.

24 January 2024 at 19:13 #709860

24 January 2024 at 19:13 #709860Turbine Guy

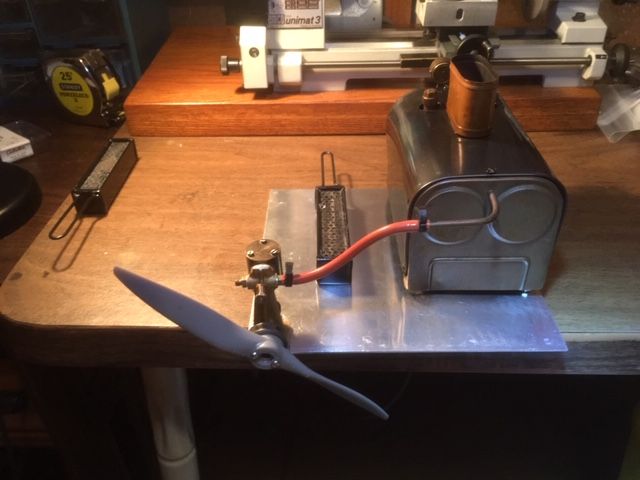

Participant@turbineguyI had a discussion with Mike Tilby about whether the velocity can go supersonic with a converging only nozzle. My sources indicate that the velocity can go supersonic as discussed in the 19/05/2019 post. Because of the large Reynolds number effects of tiny nozzles, I decided to see if this works with miniature nozzles. My estimation for the nozzle maximum velocity running on air at 24 psig, and 1.74 lbm/hr from my airbrush compressor is 1,271 ft/sec. I estimate the sonic velocity to be 1,081 ft/sec. My estimations of the velocities included the pressure loss due to friction in the nozzle. The estimated impact force for these two velocities is 8.7 grams and 7.4 grams respectively. Any reaction force in this range will indicate my estimations are reasonably correct. If the force is above 7.4 grams it will indicate the velocity can go above sonic and will give the approximate amount. If the force is at or below 7.4 grams it will indicate the flow stays at or below sonic. The following photo shows the setup I used to measure the impact force. I supported a cover plate containing the nozzle I estimated the impact forces for in my lathe tailstock. The plate was angled to where the nozzle was perpendicular to the precision scale. As shown in the attached photo the impact f

In the 3 November 2023 post I mentioned that I would try to find the distance necessary for the gas to expand to supersonic velocities when using a converging only nozzle. The quoted test indicates the distance from the exit of the nozzle to first contact does not have to be extremely short since the actual force was only 4% less than the maximum force with the fairly long distance from the nozzle to the scale. This means that if the distance from the nozzle to the first contact of the rotor is only slightly more than required for the gas to expand to supersonic velocities there will be a very small reduction in efficiency.

27 February 2024 at 15:15 #716509Turbine Guy

Participant@turbineguyI tried to reply to the 25 February 2023 post but only my response to the post was shown. None of the post I was responding to was shown so my response by itself made no sense. I am going to try to do this again in the next post.

27 February 2024 at 15:40 #716514Turbine Guy

Participant@turbineguyI wanted to make some tests of my model turbines with my Stuart Twin Drum boiler. This small simple boiler is what I hoped could be used with model turbines and be competitive with the small model steam engines. This boiler did not come with a throttle valve and was intended to be used with the Stuart ST oscillating cylinder steam engine like shown in the following photo. When I made the first nozzles for some of my model turbines they had a throat diameter of less than 0.028” so that they could be run with the Stuart Twin Drum boiler without a throttle valve. The best results of any of the model turbines I ran with the Stuart Twin Drum boiler were with Axial Turbine 2 that had a nozzle size of 0.024”. When I got my larger airbrush compressor and started testing with the Stuart 504 boiler, the optimum nozzles sizes became larger, so I had increased the nozzle sizes on all my turbines. I decided to add an orifice in the outlet tube of the Twin Drum boiler to act as a throttle and run Tangential Turbine 5B and see how the throttled performance compared with the best I have got without the throttle. The following test sheet shows this comparison. The output power turned out to be about the same even though the throttling lost over half of the energy available to Tangential Turbine 5B. This illustrated the increase in turbine efficiency running at sonic velocity compared with running at supersonic velocities. The axial turbines ran better on steam than my tangential turbines because a space between the nozzle and the rotor could be provided that would allow the steam exiting the nozzle to expand as needed to go supersonic. Moving the axial rotor away from the nozzle worked but was a compromise. Even with the compromises of the turbines shown in the first two tests of the following test sheet, they appeared to exceed the performance of the Stuart ST oscillating cylinder steam engine the Stuart Twin Drum boiler was intended to be used with. The test I made with a Stuart ST steam engine with everything the way it came and run with the Stuart Twin Drum boiler; it turned an APC 8×6 propeller at approximately 1,500 rpm. This propeller requires 0.4 watts to run at this speed according to the manufacture’s propeller performance sheets. The turbines would require a 12:1 speed reducer to run at the Stuart ST speed. This would probably require two stages and assuming the 80% efficiency per stage I found with the test of Radial Turbine 1, the power of the turbines would be reduced to 0.7 watts. This is still quite a bit better than the 0.4 watts of the Stuart ST steam engine.

The third test was running the steam without being throttled. Even with the large nozzle size, the flow out of the boiler was steady but at a very low pressure. Although the overall energy output of the boiler was less than half than with throttling or a small nozzle, the power and efficiency increased significantly. These tests indicate that a better way to achieve supersonic velocities is needed to run at the higher pressures.

The type of nozzle shown in the last post would provide this space without increasing the leakage caused by the gaps and should help any of the turbines that run on supersonic air or steam.

I added the tests of Tangential Turbine 5C to the test sheet shown in this post to illustrate how effective using an insert is in solving the problem of giving the gas a place to expand. I will show the test results using air with the 0.024′ nozzle in the next post using a quote from a post showing the results and how the insert fit in Tangential Turbine 5C and Axial Turbine 4D.

27 February 2024 at 15:57 #716517

27 February 2024 at 15:57 #716517Turbine Guy

Participant@turbineguyThe following test sheet shows the performance of Axial Turbine 4D and Tangential Turbine 5C running on air I said I was going to show after the 27/03/2023 post that also included the following drawings. I will look at the reasons for this performance in the next posts.

This post showed that the insert was as effective running with air.

28 February 2024 at 16:29 #716697Turbine Guy

Participant@turbineguyI tried to add an insert like shown in the following drawing. This required a new cover that I had printed in aluminum. I tried to make the insert about half the length of the actual size shown in the following drawing. I found that the minimum length required is about ⅛”. You need this much length to get enough grip on the insert to resist the machining forces. I picked the size of the insert based on the largest OD miniature tubing I could find with an ID of 0.022”. I positioned the insert in the cover so that the distance of 0.032” from the closest edge of the nozzle bore to the face of the cover was approximately the 0.8mm (0.031”) thickness of the gasket Werner Jeggli used to provide space for steam to expand before contacting the rotor. This distance has worked well for Werner with nozzles this small and pressures up to 4 Bar (60 psig). I tried using a gasket as explained in the 30 October 2023 post but don’t think it allowed enough space for the 0.042” nozzle size. I was able to make the cover and insert to the dimensions shown on the following drawing. The insert went almost all the way into the cover but when I tapped it with a hammer to get it all the way in, the cover broke open as shown in the dark areas on the right of the following photo. The miniature tubing the insert was made from was hardened stainless steel so it required quite a bit of force to get the turning tools to bite into it and the tubing had to extend out quite a ways to get clearance for the turning tools. I think this caused the OD of the insert to have a small taper which would have caused a very large radial force when the insert was tapped on the end with a hammer.

7 March 2024 at 13:55 #718742

7 March 2024 at 13:55 #718742Turbine Guy

Participant@turbineguyI decided to try adding an insert in Axial Turbine 2 and call this assembly Axial Turbine 2B as shown on the following drawing. Thor Hansen and Mike Tilby suggested that I use a Dremel cutoff disk to cut the miniature tube when making the insert. This really simplified making the tiny insert to the dimensions shown on the following drawing. I ran a test with steam using my Stuart Twin Drum boiler like I did in the test described in the 27 February 2024 post and added the results of the test to the table shown in that post. The updated table is shown below. The improvement in performance of Axial Turbine 2 with the addition of the insert is a little misleading. Two other significant improvements were made to Axial Turbine 2 after the first test. The first was centering the rotor on the shaft. The first shaft hole I made in the rotor was slightly off center so when I made the shaft smaller for the dental ball bearings, I did a better job of centering it. The second improvement was using the dental ball bearings that are self lubricating, work well with air or steam (300 F maximum), and have very low friction. As shown in the following table, these three improvements more than doubled the power and efficiency of Axial Turbine 2.

When I ran the test with Axial Turbine 2B, I measured the amount of water used as shown in the notes of the following table. The moisture content was not consistent. When the test first started, the turbine ran at a much lower speed than later in the test. Drops of water were dripping out of the turbine outlet. After a few minutes of running, the dripping stopped and the speed increased significantly and remained constant for the rest of the test. The 0.024” nozzle size turned out to be about right for the Stuart Twin Drum boiler since the pressure stayed at approximately 40 psig once the turbine warmed up and the relief valve discharges at just a little over 40 psig. This allowed me to run at almost the maximum pressure without losing any steam.

9 March 2024 at 16:26 #719014

9 March 2024 at 16:26 #719014Turbine Guy

Participant@turbineguyI opened up the hole the insert would discharge into, shown as 0.040” (H) on the drawing in the last post and ran a test running on air before installing the insert and added it to the following table. I then ran the test with the insert installed and added it to the table. I also added the results of the test shown for Axial Turbine 4D in the 27 February 2024 post. This updated the table to include the different nozzle sizes and tests with inserts for all the turbines running on air supplied by the Master TC-96T airbrush compressor.

15 March 2024 at 18:14 #720028

15 March 2024 at 18:14 #720028Turbine Guy

Participant@turbineguyI updated the table showing the tests running on steam as shown below. I added all the tests I felt were significant and added the post date and page number of the post that best describes the turbine and the test similar to the table running on air in the previous post. These two tables show the most significant tests I have made running on air or steam and the progression in the power and efficiency of my turbines.

9 April 2024 at 19:14 #724973

9 April 2024 at 19:14 #724973Turbine Guy

Participant@turbineguyI added a globe valve to the outlet line of my Stuart Twin Drum boiler as shown in the following photo. I was anxious to do a test after installing the valve and ran with Tangential Turbine 5B clamped to a heavy base plate like used in previously running on air. Apparently so much heat was conducted into the base plate and carried away by the air blown over the housing by the propeller that I was not able to get as good performance as I was able to obtain without the valve. These heat losses are not a problem when running with air since air expands to quite a low temperature in the nozzle so the base plate and air blowing over the housing actually add warmth. This is a big advantage for running with air. I made a few more tests with the turbine insulated from the support so that the heat lost to the support was negligible but the heat loss to the air blowing over the housing was still very high. I insulated the turbine from the vise I held it with by inserting folded paper on each contact side as can be seen in the following photo. I added two of the tests in the following table. The test of 4/8/2024 was with the valve opened to the point that the boiler pressure remained at 40 psig for the entire length of the run. After running for a few minutes, the speed remained at the value shown for the rest of the test. The globe valve allowed the pressure to be set to the value that the boiler supplies the most energy, so the turbine made the same power as the 4/6/2024 test with less mass flow. This increased the run time from 8.9 minutes to 11.3 minutes to empty the boiler filled with ½ cup of water. I’ve always tried to get the highest turbine efficiency but I think being able to run significantly longer at the same power is even more important. If you can make the nozzle size to match the optimum output of the boiler and provide the space for the steam to expand to supersonic velocities this will provide the best performance like in the test of 4/6/2023. The run time with ½ cup of water for the 4/6/2023 test was 10 minutes so adding the small nozzle and space for the steam to expand to supersonic velocities increased the power and run time compared with the 4/6/2024 test and also provided the best turbine efficiency even with relatively high moisture content.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Stationary engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Amadeal AMABL210E Review – Any Requests?

1

2

Started by:

JasonB

in: Model Engineer & Workshop

JasonB

in: Model Engineer & Workshop

- 16

- 36

-

4 July 2025 at 17:37

Emgee

-

The Perpetual Demise of the Model engineer

Started by:

Luker in: Model engineering club news

- 13

- 25

-

4 July 2025 at 17:06

JasonB

JasonB

-

Colchester Chipmaster Clutch question

Started by:

Peter_H in: Manual machine tools

- 3

- 5

-

4 July 2025 at 16:44

notlobgp14

-

Advice moving 3x machines

Started by:

choochoo_baloo in: Workshop Techniques

- 5

- 5

-

4 July 2025 at 15:46

Bazyle

Bazyle

-

Speed camera

1

2

3

Started by:

David George 1

in: The Tea Room

David George 1

in: The Tea Room

- 23

- 52

-

4 July 2025 at 15:35

Clive Steer

-

Firth Valve Gear

Started by:

Andy Stopford in: Traction engines

- 10

- 22

-

4 July 2025 at 14:42

duncan webster 1

-

What Did You Do Today 2025

1

2

…

6

7

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 173

-

4 July 2025 at 14:28

Nick Wheeler

-

A Persistent Scam

Started by:

Chris Crew in: The Tea Room

- 5

- 5

-

4 July 2025 at 14:23

Speedy Builder5

-

ML10 backgear

Started by:

alexander1 in: Manual machine tools

- 3

- 3

-

4 July 2025 at 13:34

Bazyle

Bazyle

-

Boxford lathe & vertical mill VFD conversion help with start stop

Started by:

Andrew Schofield in: Beginners questions

- 2

- 3

-

4 July 2025 at 10:38

Andrew Schofield

-

Hemmingway rotary broaching kit

Started by:

YouraT in: Workshop Tools and Tooling

- 4

- 4

-

4 July 2025 at 09:02

jimmy b

jimmy b

-

Bentley BR2 Rotary Aero Engine

Started by:

notlobgp14 in: Miscellaneous models

- 3

- 4

-

4 July 2025 at 06:54

JasonB

JasonB

-

Collet closer identification.

Started by:

vic newey

in: Workshop Tools and Tooling

vic newey

in: Workshop Tools and Tooling

- 10

- 15

-

3 July 2025 at 22:36

richlb

-

Starrett micrometer.

Started by:

Graeme Seed in: Workshop Tools and Tooling

- 5

- 10

-

3 July 2025 at 21:25

peak4

peak4

-

A grasshopper of unknown vintage

Started by:

mikemunson in: Stationary engines

- 3

- 3

-

3 July 2025 at 20:21

Charles Lamont

-

New (but well aged) member

Started by:

mikemunson in: Introduce Yourself – New members start here!

- 4

- 4

-

3 July 2025 at 19:55

noel shelley

-

New member from Lancashire

Started by:

mannyroad in: Introduce Yourself – New members start here!

- 7

- 15

-

3 July 2025 at 19:14

notlobgp14

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 10

- 19

-

3 July 2025 at 18:35

Paul McDonough

-

Twin Engineering’s heavy mill/drill quill removal

Started by:

Martin of Wick in: Manual machine tools

- 10

- 21

-

3 July 2025 at 17:53

David George 1

David George 1

-

Loctite axles

Started by:

steve2250 in: General Questions

- 5

- 6

-

3 July 2025 at 12:22

parovoz

-

Comments (constructive) on the New Forum Software

1

2

…

34

35

Started by:

JasonB

in: New Forum Software questions, comments and Test Threads

JasonB

in: New Forum Software questions, comments and Test Threads

- 134

- 875

-

3 July 2025 at 10:25

Emgee

-

Grimsby & Cleethorpes MES on the BBC

Started by:

Chris Crew in: The Tea Room

- 1

- 1

-

3 July 2025 at 08:51

Chris Crew

-

Injectors

Started by:

pansy123 in: General Questions

- 6

- 7

-

3 July 2025 at 07:05

Dave Wootton

-

Pattern Makers Vice

Started by:

Vic

in: The Tea Room

Vic

in: The Tea Room

- 7

- 9

-

2 July 2025 at 21:51

KEITH BEAUMONT

KEITH BEAUMONT

-

J&S grinder – belt which way ?

Started by:

gerry madden in: Manual machine tools

- 7

- 9

-

2 July 2025 at 21:44

not done it yet

-

Amadeal AMABL210E Review – Any Requests?

1

2

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Amadeal AMABL210E Review – Any Requests?

- The Perpetual Demise of the Model engineer

- Colchester Chipmaster Clutch question

- Advice moving 3x machines

- Speed camera

- Firth Valve Gear

- What Did You Do Today 2025

- A Persistent Scam

- ML10 backgear

- Boxford lathe & vertical mill VFD conversion help with start stop