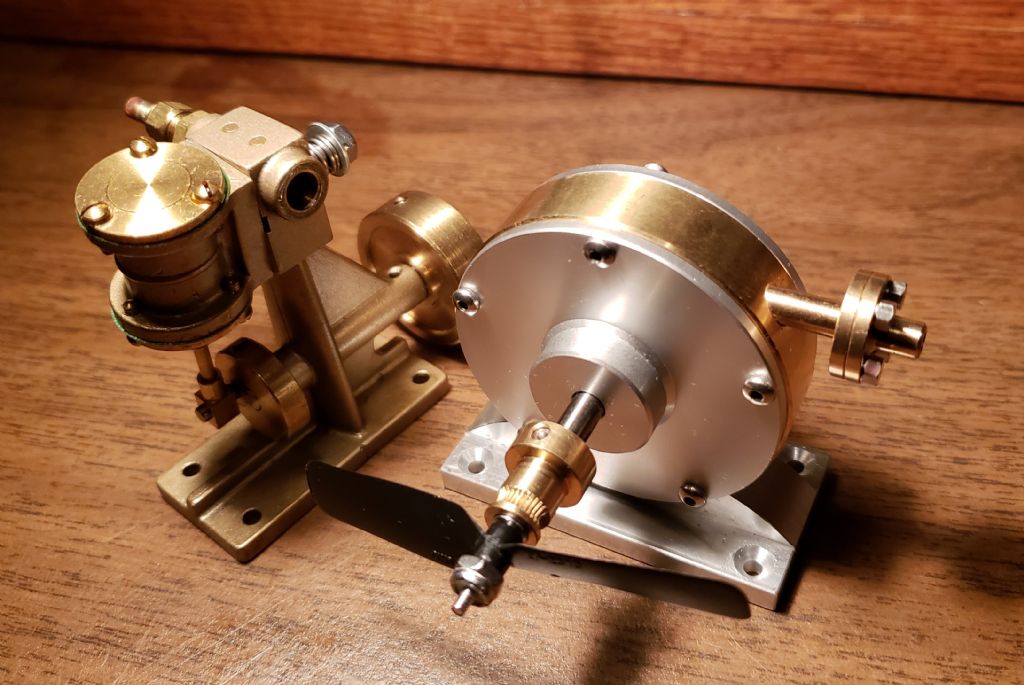

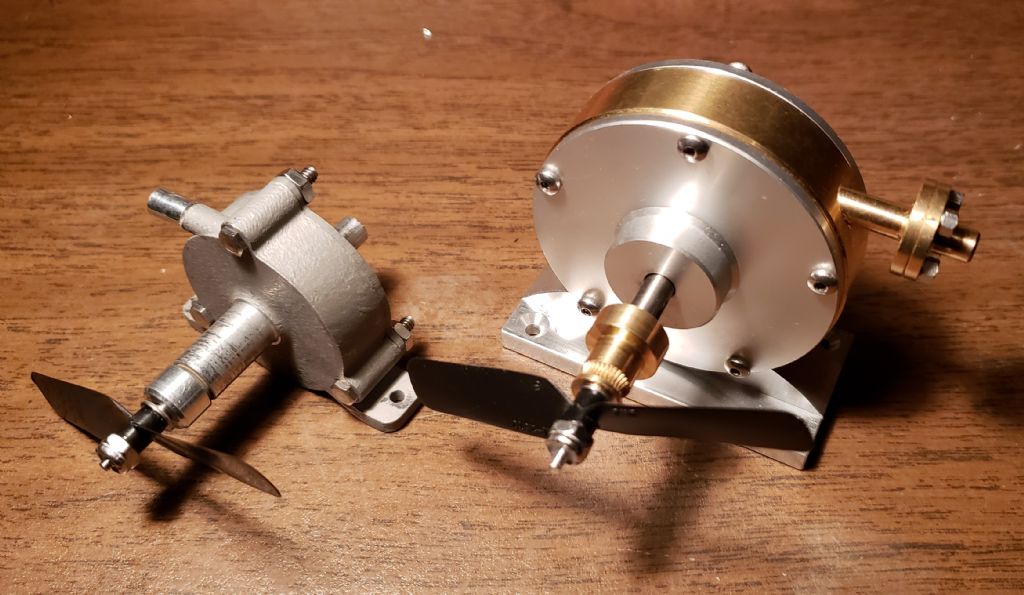

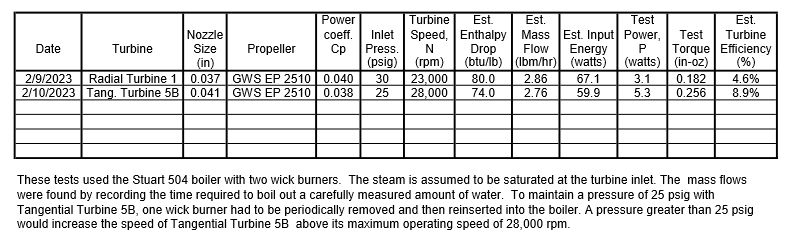

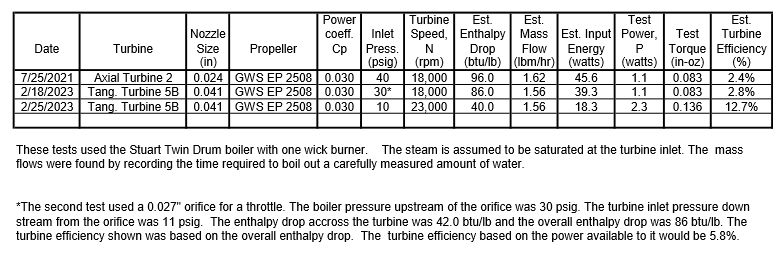

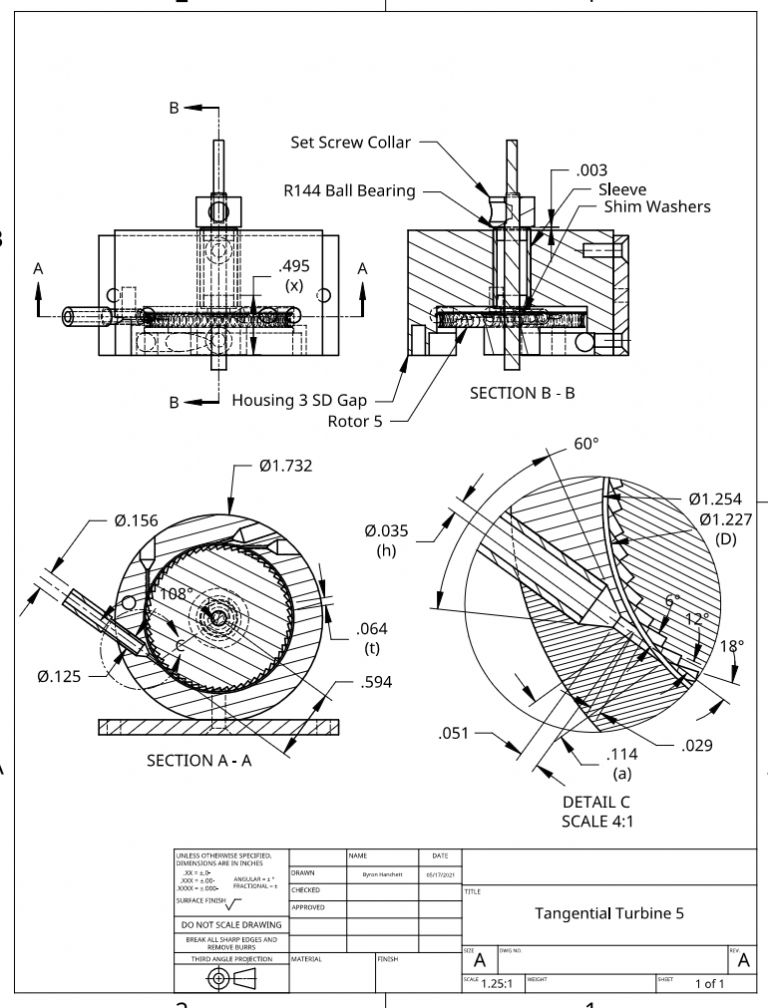

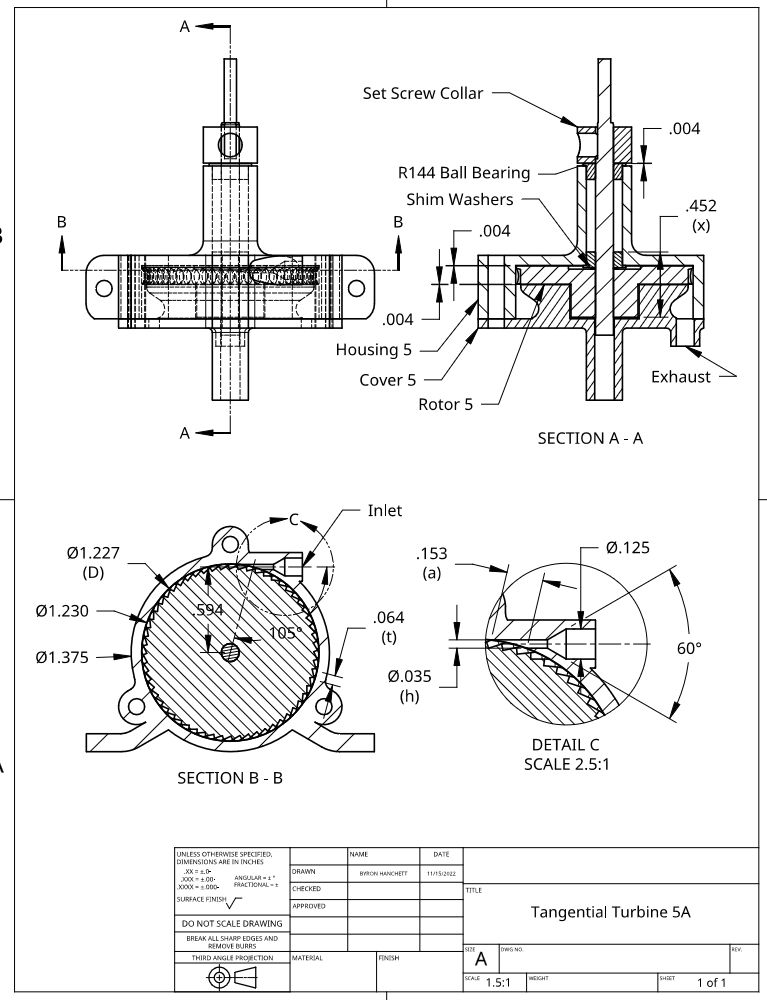

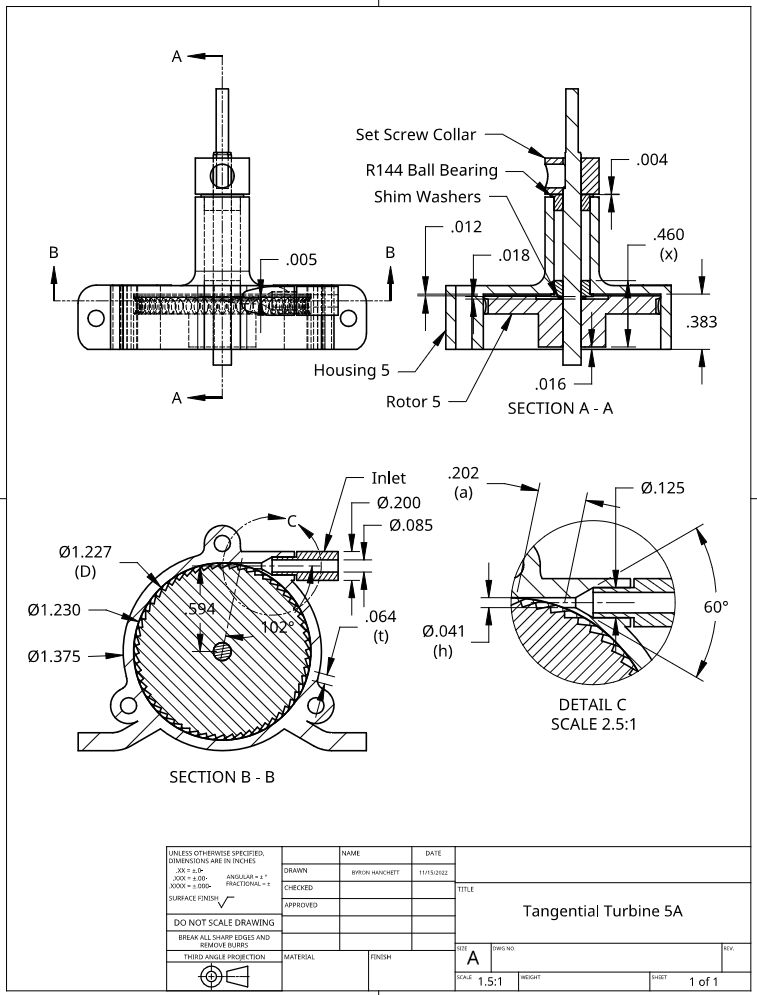

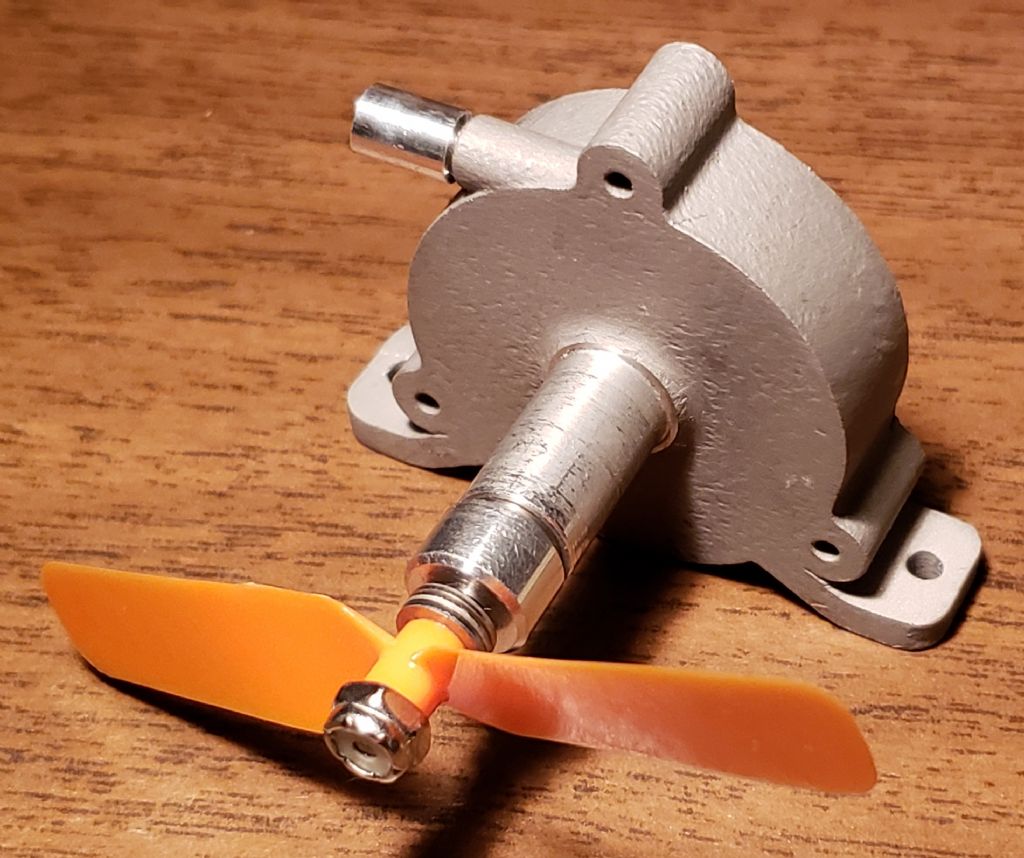

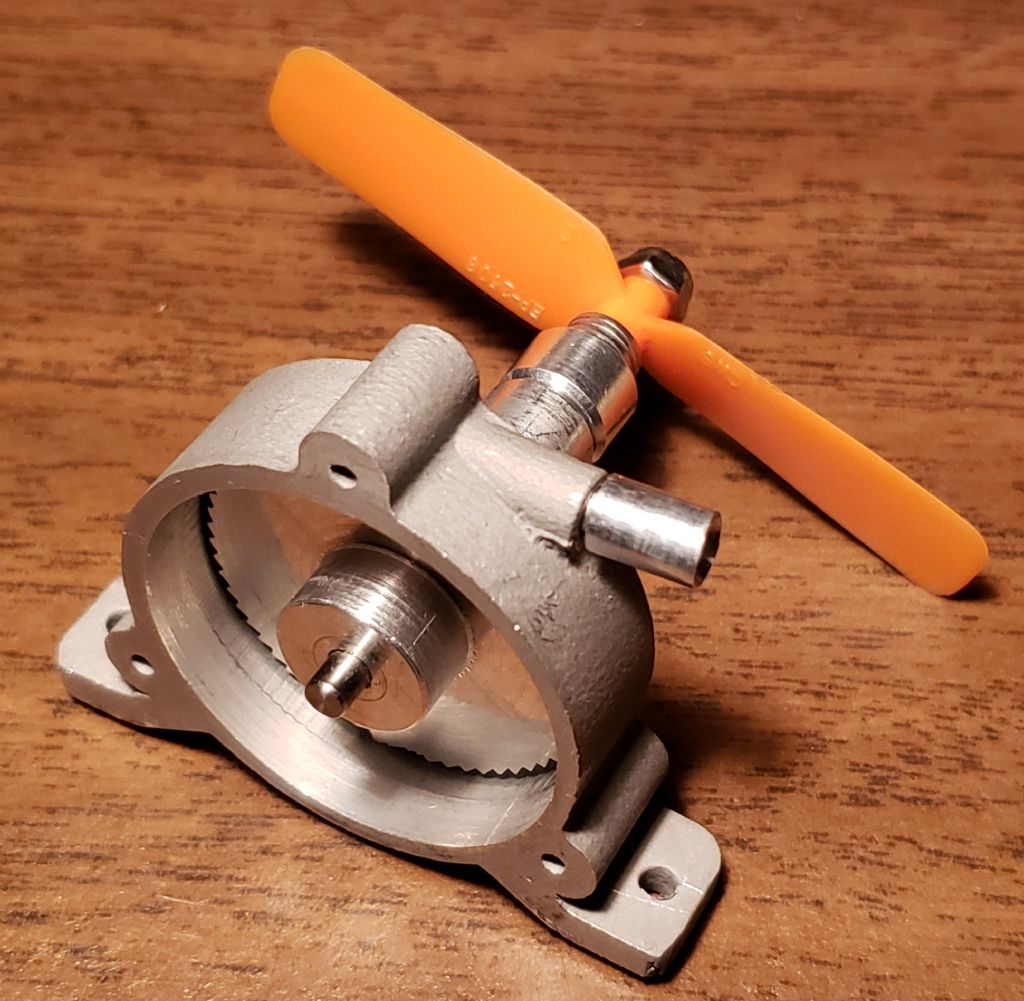

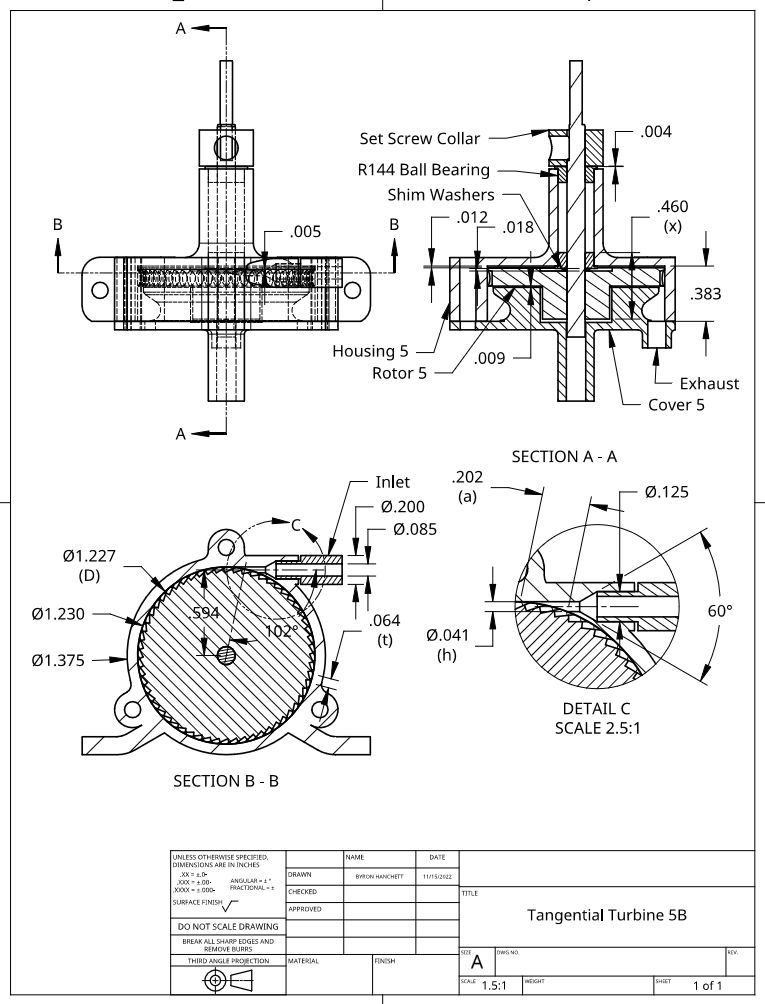

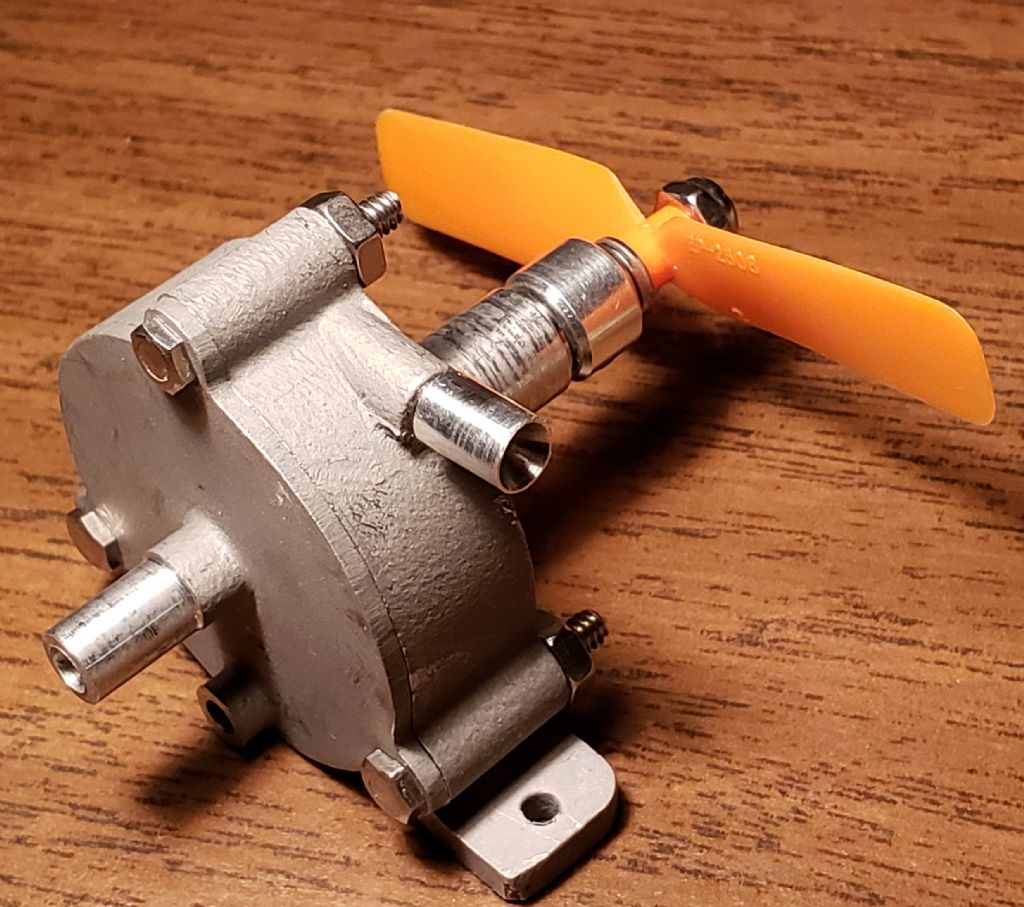

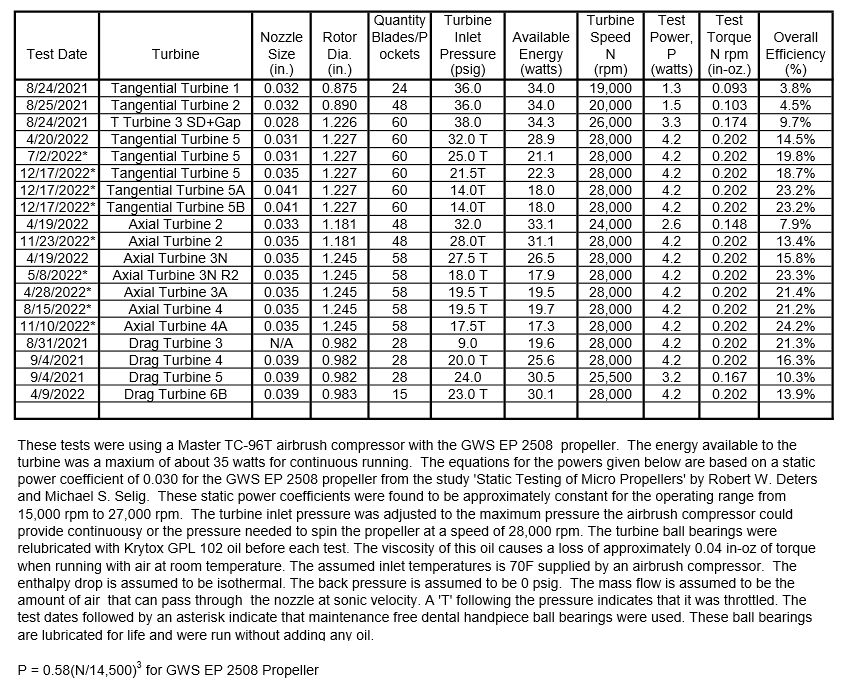

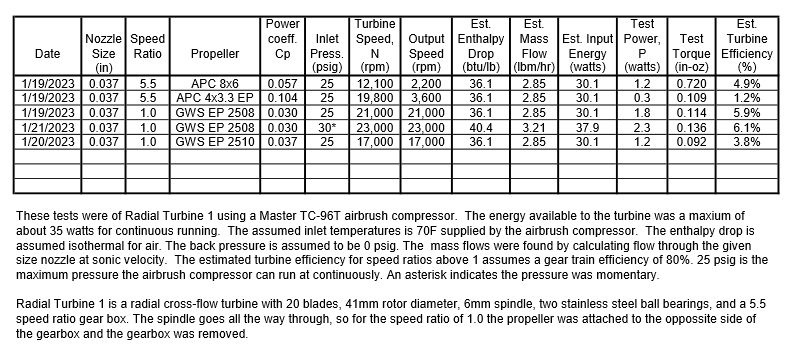

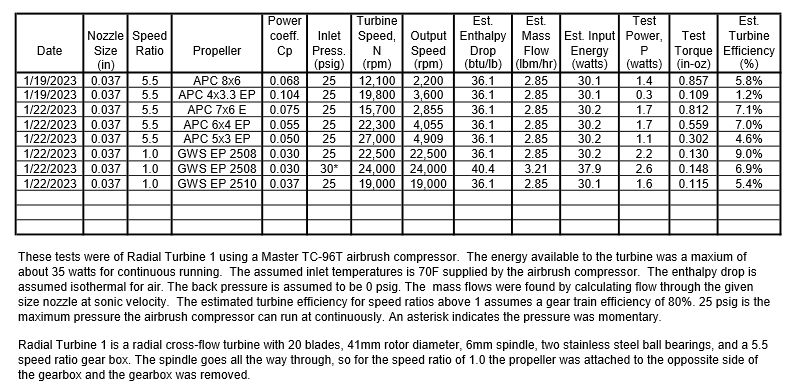

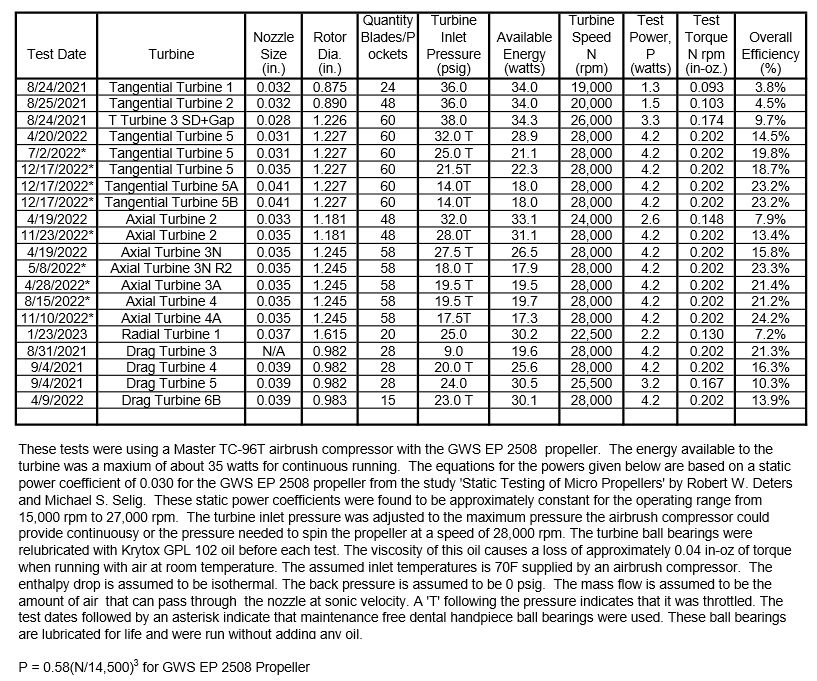

I wanted to make some tests of my model turbines with my Stuart Twin Drum boiler. This small simple boiler is what I hoped could be used with model turbines and be competitive with the small model steam engines. This boiler did not come with a throttle valve and was intended to be used with the Stuart ST oscillating cylinder steam engine like shown in the following photo. When I made the first nozzles for some of my model turbines they had a throat diameter of less than 0.028” so that they could be run with the Stuart Twin Drum boiler without a throttle valve. The best results of any of the model turbines I ran with the Stuart Twin Drum boiler were with Axial Turbine 2 that had a nozzle size of 0.024”. When I got my larger airbrush compressor and started testing with the Stuart 504 boiler, the optimum nozzles sizes became larger, so I had increased the nozzle sizes on all my turbines. I decided to add an orifice in the outlet tube of the Twin Drum boiler to act as a throttle and run Tangential Turbine 5B and see how the throttled performance compared with the best I have got without the throttle. The following test sheet shows this comparison. The output power turned out to be about the same even though the throttling lost over half of the energy available to Tangential Turbine 5B. This illustrated the increase in turbine efficiency running at sonic velocity compared with running at supersonic velocities. The axial turbines ran better on steam than my tangential turbines because a space between the nozzle and the rotor could be provided that would allow the steam exiting the nozzle to expand as needed to go supersonic. Moving the axial rotor away from the nozzle worked but was a compromise. Even with the compromises of the turbines shown in the first two tests of the following test sheet, they appeared to exceed the performance of the Stuart ST oscillating cylinder steam engine the Stuart Twin Drum boiler was intended to be used with. The test I made with a Stuart ST steam engine with everything the way it came and run with the Stuart Twin Drum boiler; it turned an APC 8×6 propeller at approximately 1,500 rpm. This propeller requires 0.4 watts to run at this speed according to the manufacture’s propeller performance sheets. The turbines would require a 12:1 speed reducer to run at the Stuart ST speed. This would probably require two stages and assuming the 80% efficiency per stage I found with the test of Radial Turbine 1, the power of the turbines would be reduced to 0.7 watts. This is still quite a bit better than the 0.4 watts of the Stuart ST steam engine.

The third test was running the steam without being throttled. Even with the large nozzle size, the flow out of the boiler was steady but at a very low pressure. Although the overall energy output of the boiler was less than half than with throttling or a small nozzle, the power and efficiency increased significantly. These tests indicate that a better way to achieve supersonic velocities is needed to run at the higher pressures.

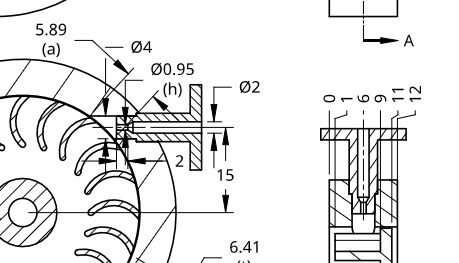

The type of nozzle shown in the last post would provide this space without increasing the leakage caused by the gaps and should help any of the turbines that run on supersonic air or steam.

Edited By Turbine Guy on 25/02/2023 18:50:11

Turbine Guy.

gaps. The wave washers would probably eliminate this noise and extend the life of the bearings.

gaps. The wave washers would probably eliminate this noise and extend the life of the bearings.