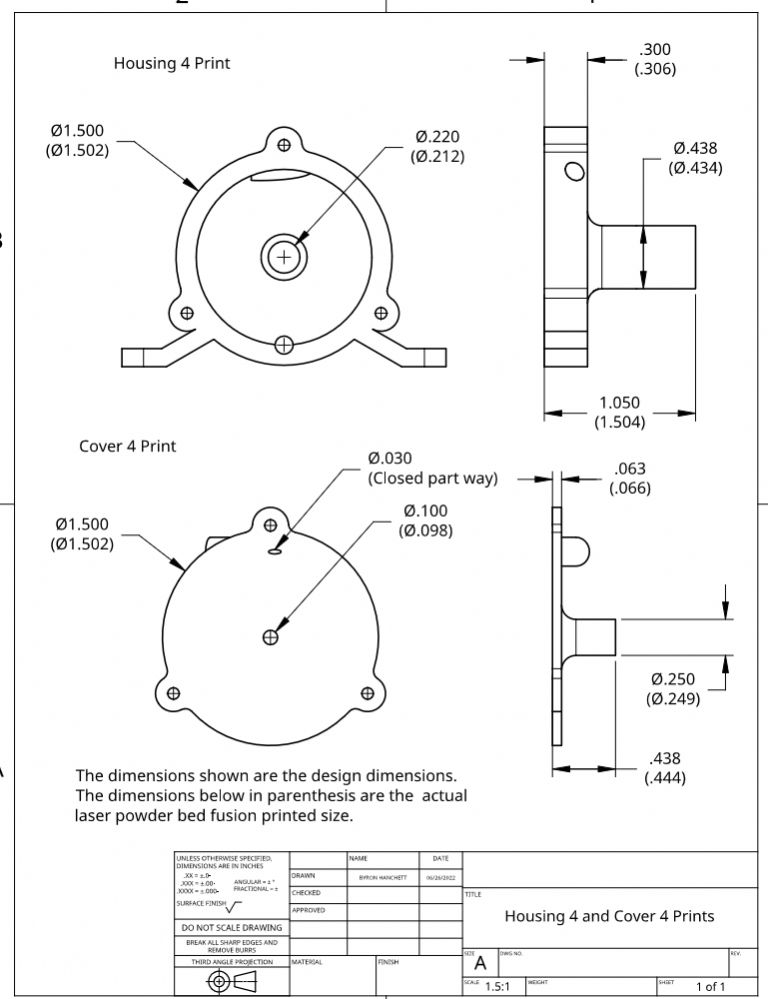

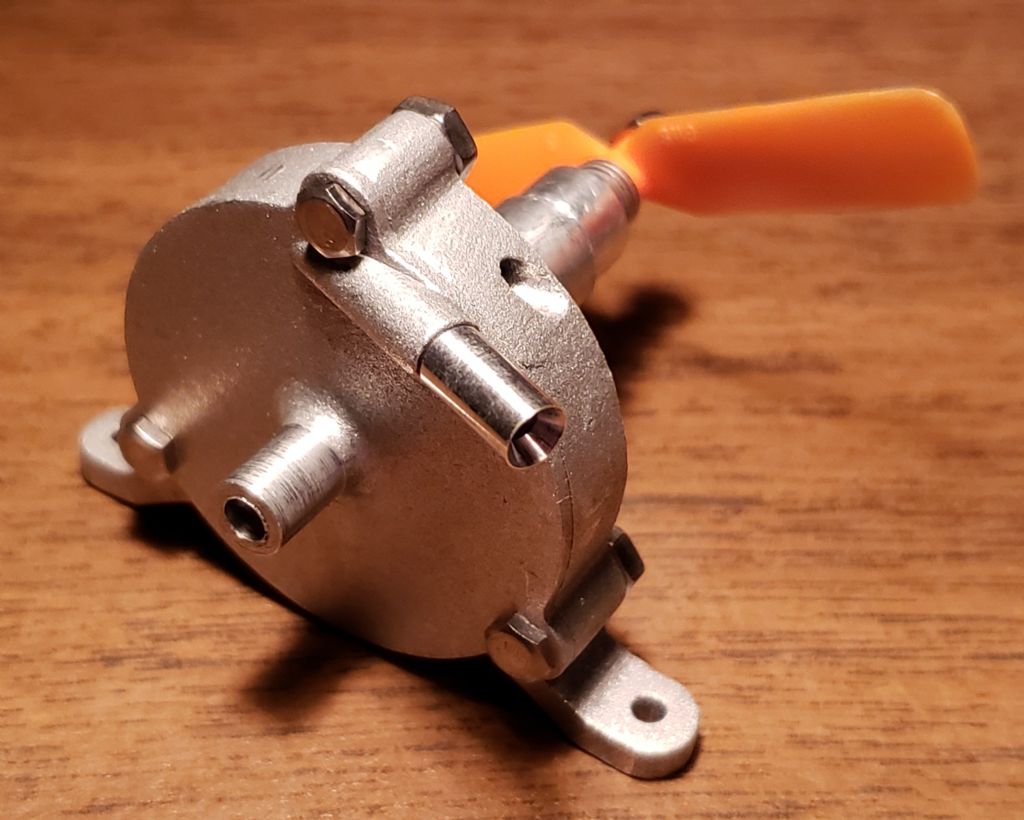

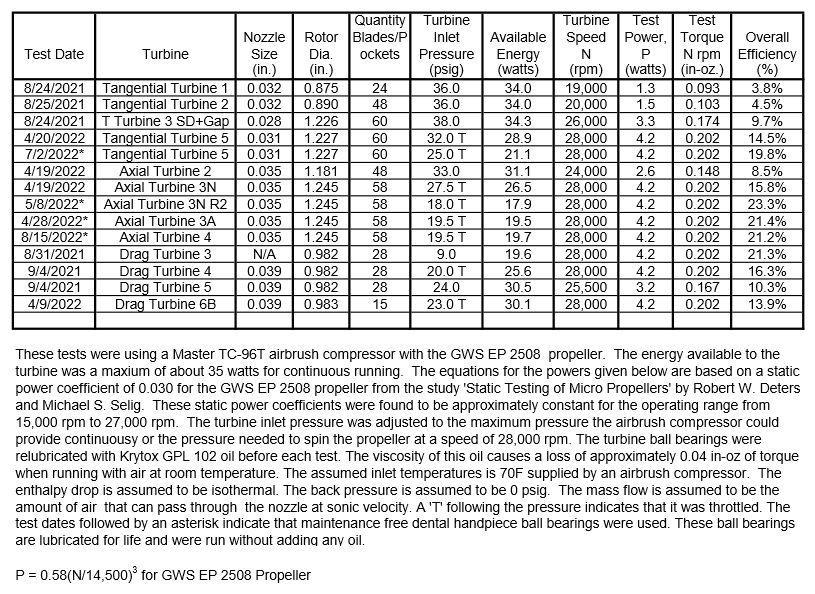

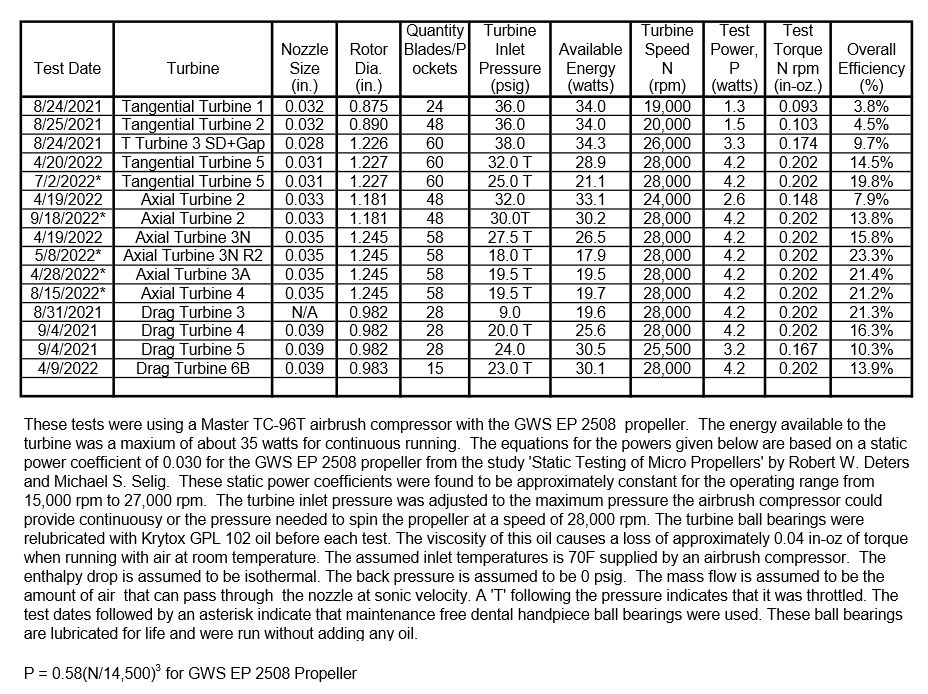

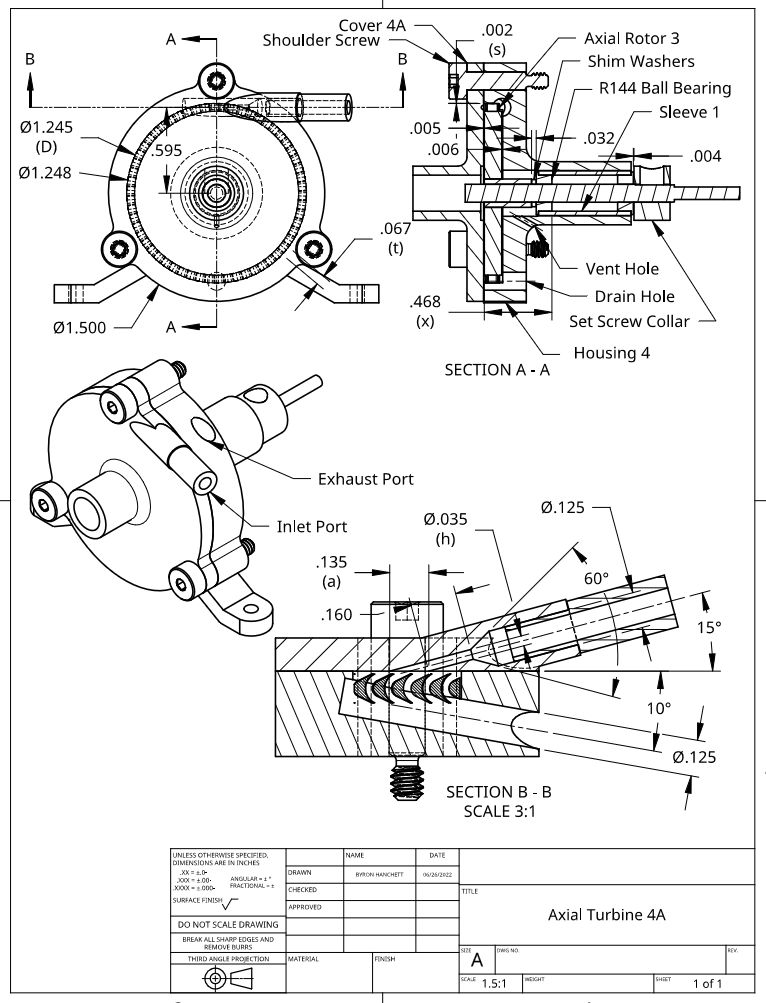

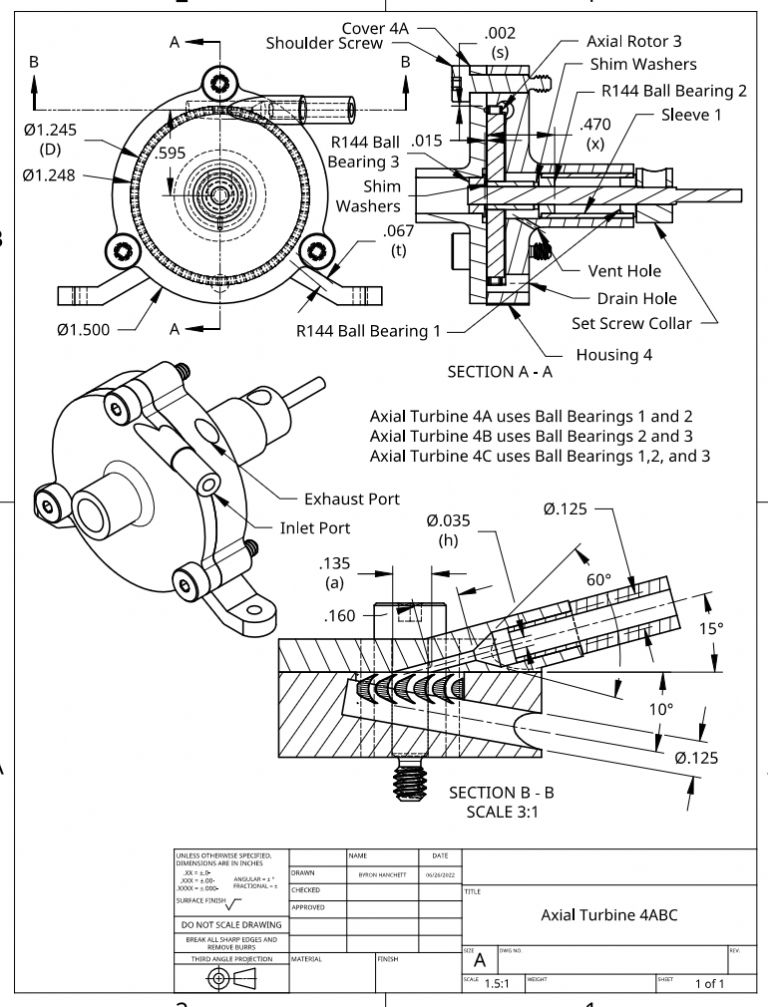

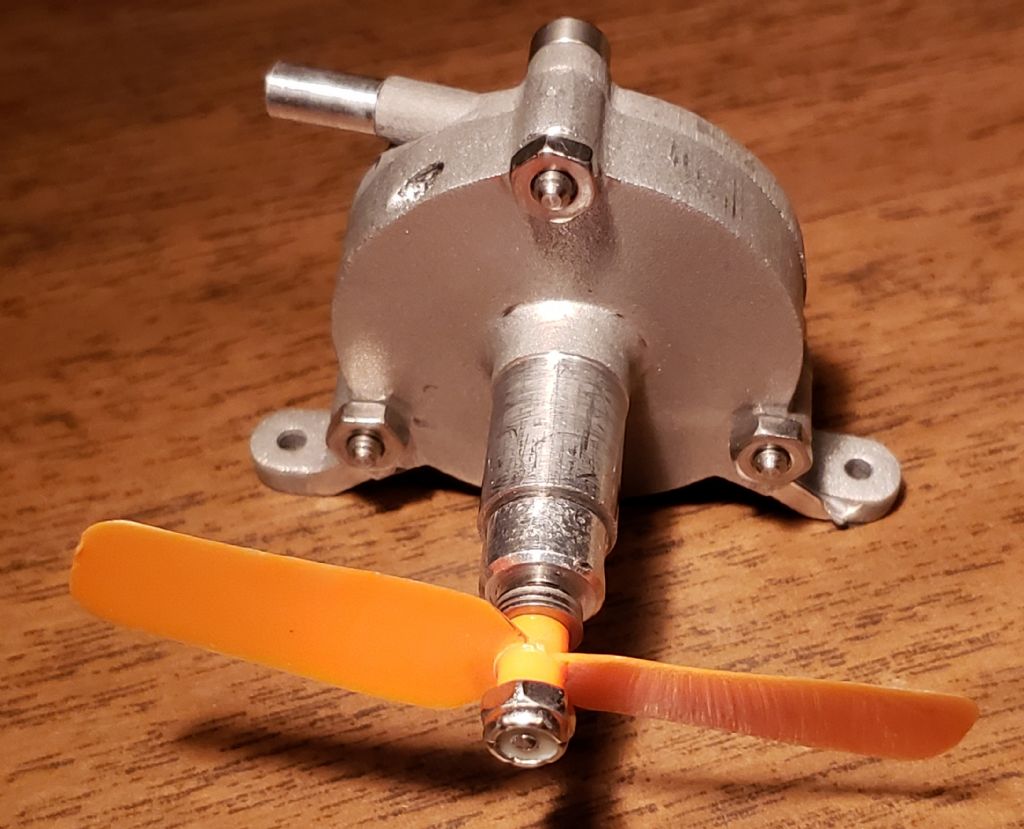

I finished the first round of testing of Axial Turbine 4. I need to explain why I prefer to find the optimum position of the rotor using the APC 4×3.3 EP propeller even though it cannot get the power and efficiency of the GWS 2508 EP propeller. When I made my first turbine, I thought that a right-hand propeller would spin clockwise when looking at the front. I found out that it should spin clockwise when looking at the back like from the cockpit of a plane. I could not get a left-hand propeller in the small size, but I can put the propeller on backwards, so it is rotating in the correct direction. This pushes the air away from the turbine instead of pulling the air over the turbine. I should have designed my next turbines to run the correct direction. As I have mentioned in earlier posts the ball bearings need some axial clearance to run with the least resistance. I have found that at least 0.004” gives the best results. Running the propellers left-hand, pushes the rotor away from the inner ball bearing and toward the cover. The clearance must be on the outer ball bearing, so I use a 0.004” feeler gage between it and the set screw collar. The APC 4×3.3 EP propeller is a left-hand propeller, so it pulls the rotor toward the inner ball bearing and the rotor shims control its position. This is more precise than using the feeler gage. The right-hand propeller has another advantage when held on with a nut. If something strikes the propeller while running, the force is in a direction to tighten the nut. Running the propellers left-hand like I have been doing has the opposite effect. During these last tests, I struck the propeller while it was running and it loosened the nut enough to let the propeller slip. I heard the speed raise way above the 28,000 rpm limit I had been running. Fortunately, the rotational losses were large enough to keep the speed below the breaking point of the rotor. Sorry for using such a long winded explanation, but I think it is important to show the advantages of using a right-hand propeller and running it in the correct direction.

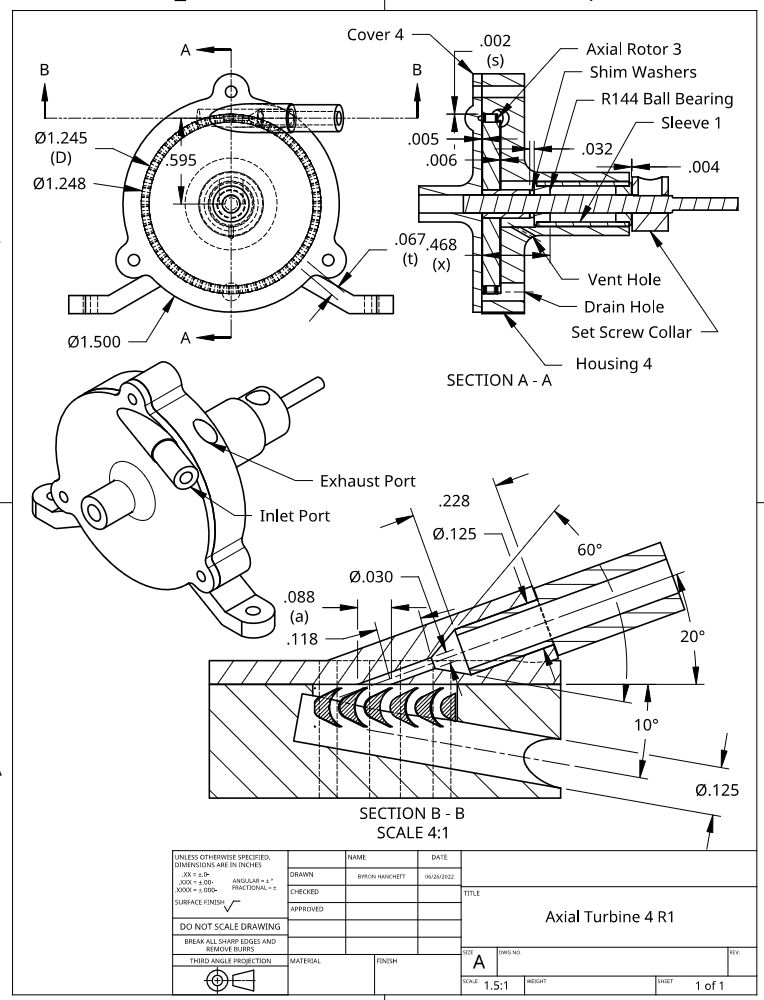

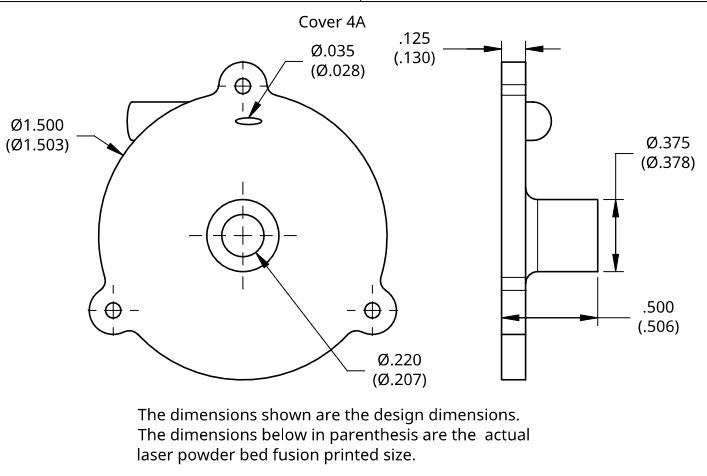

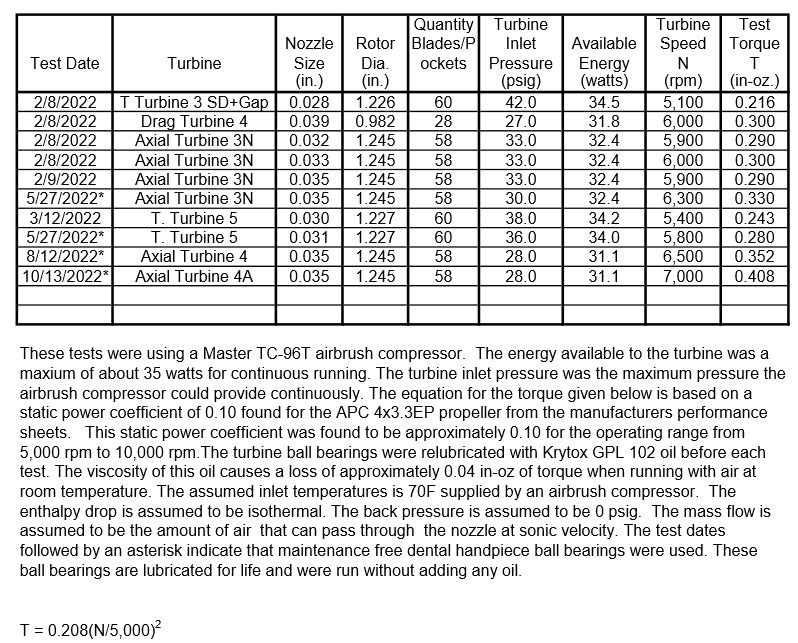

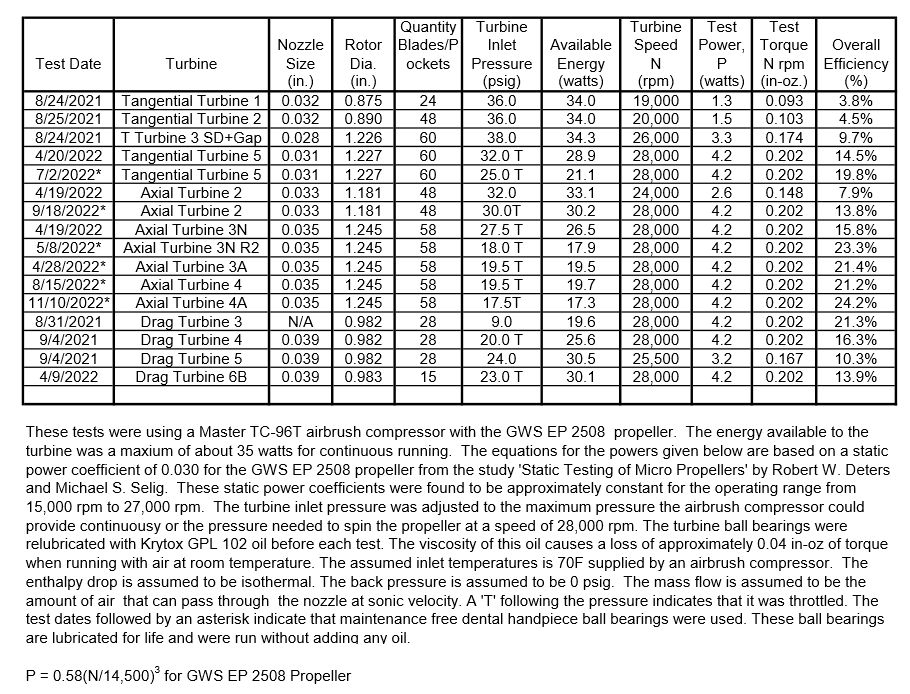

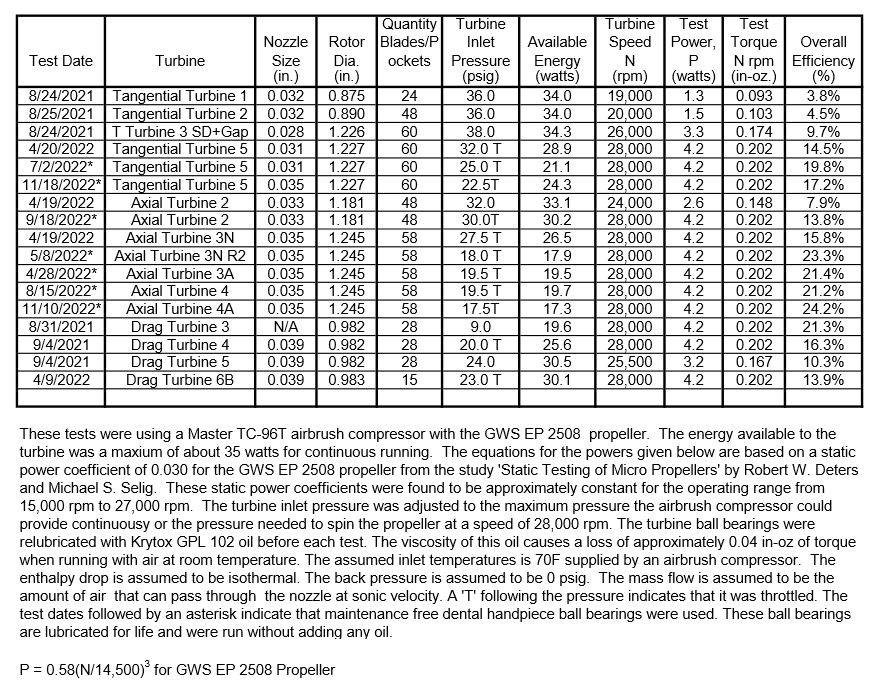

I updated the table shown in the 13/03/2022 Post to include the best performance I got with Axial Turbine 4 using the APC 4/3.3 EP propeller as shown below. I will update the table shown in the last post and add it in the next post that will explain why I need to look at the performance at low and high speeds.

Turbine Guy.