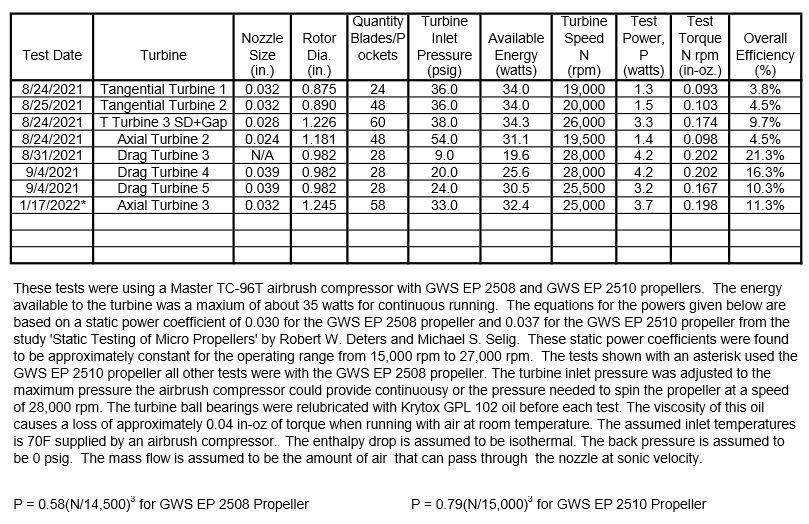

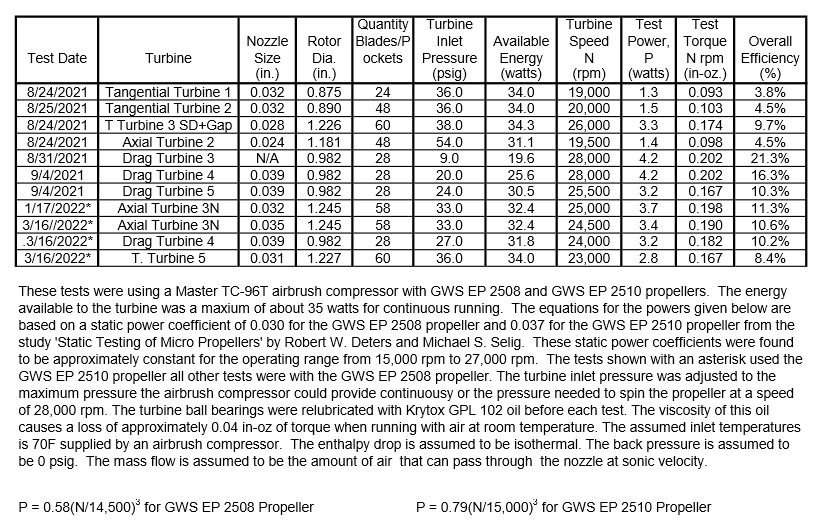

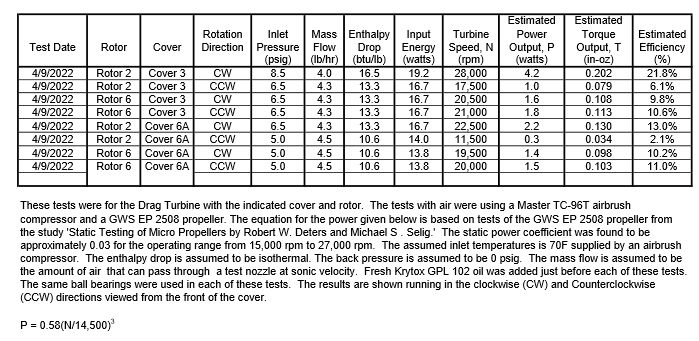

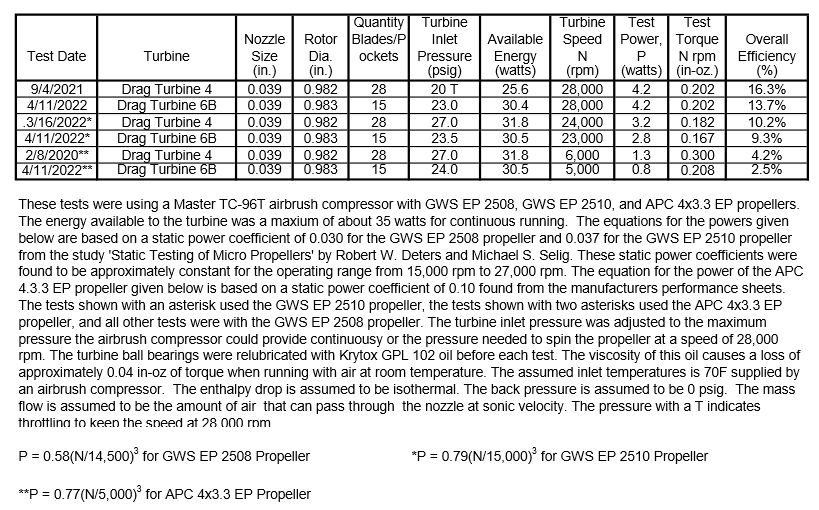

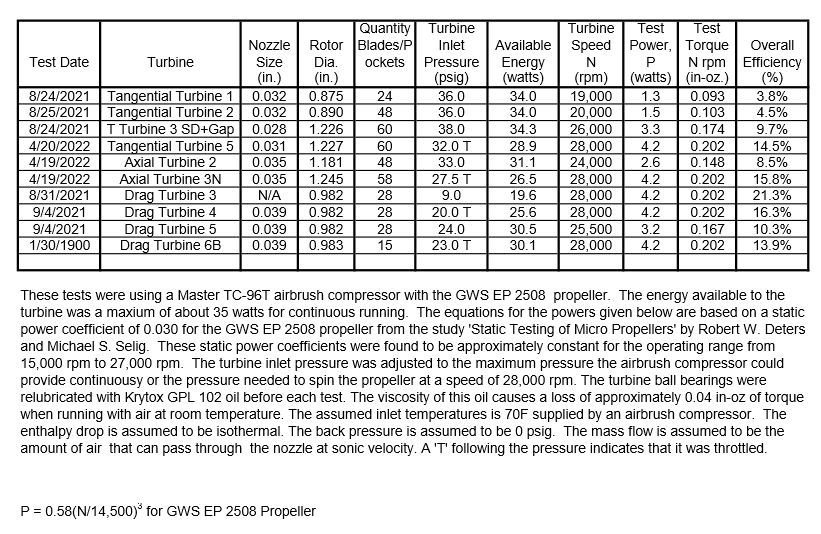

I believe the fairest way to compare the different turbines is to run them with the same propeller, with the same energy source, and at as close to the same speed as possible. Since most of the turbines I have tested used the GWS EP 2508 propeller, I decided to make a test sheet using only this propeller. Since the latest turbines can overpower this propeller, I throttled the air to keep the propeller to a maximum speed of 28,000 rpm. The throttling reduces the energy available to the turbine, so the efficiency of the turbine is the best comparison of the performance. The lower the energy required to turn the propeller at its maximum speed results in the highest efficiency.

I decided to remove the sleeve in the nozzle of Axial Turbine 2 and run a test with a nozzle size closer to the other turbines. I successfully removed the sleeve in the nozzle bore so I could change the diameter from 0.024” to 0.035”. The 0.035” diameter gave me the best performance and is better suited to my largest airbrush compressor.

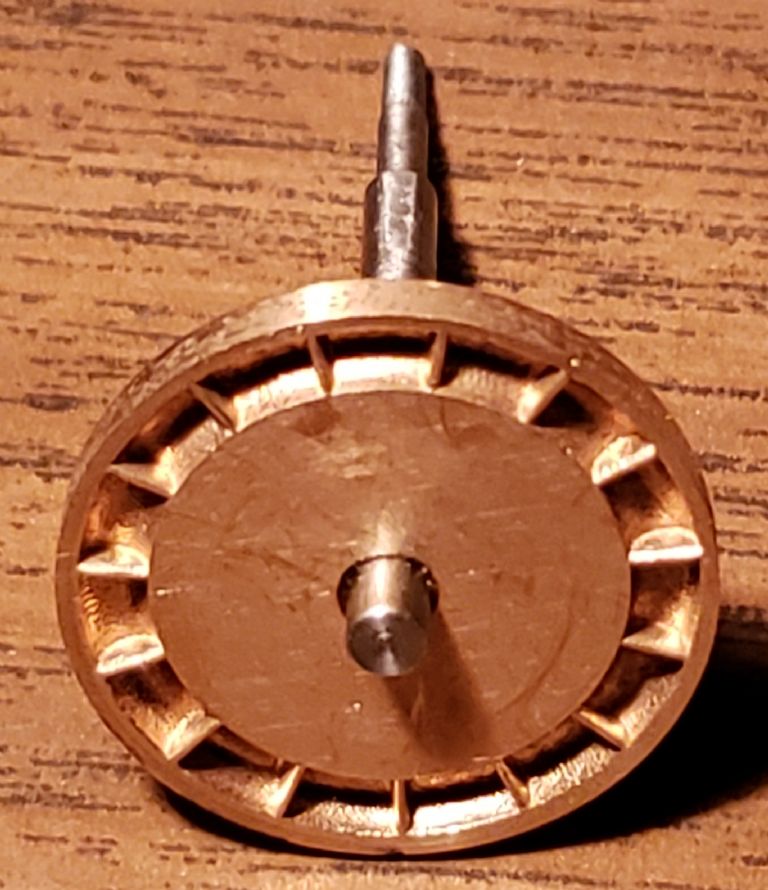

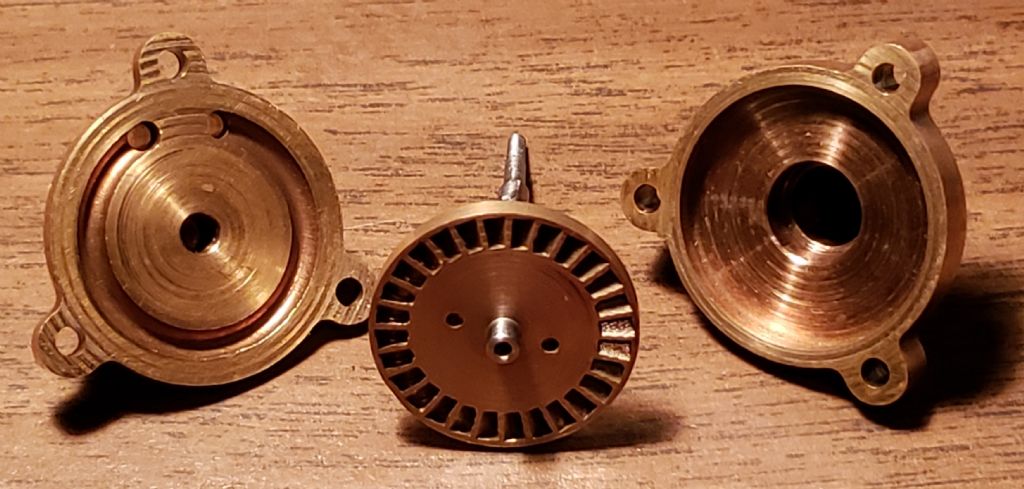

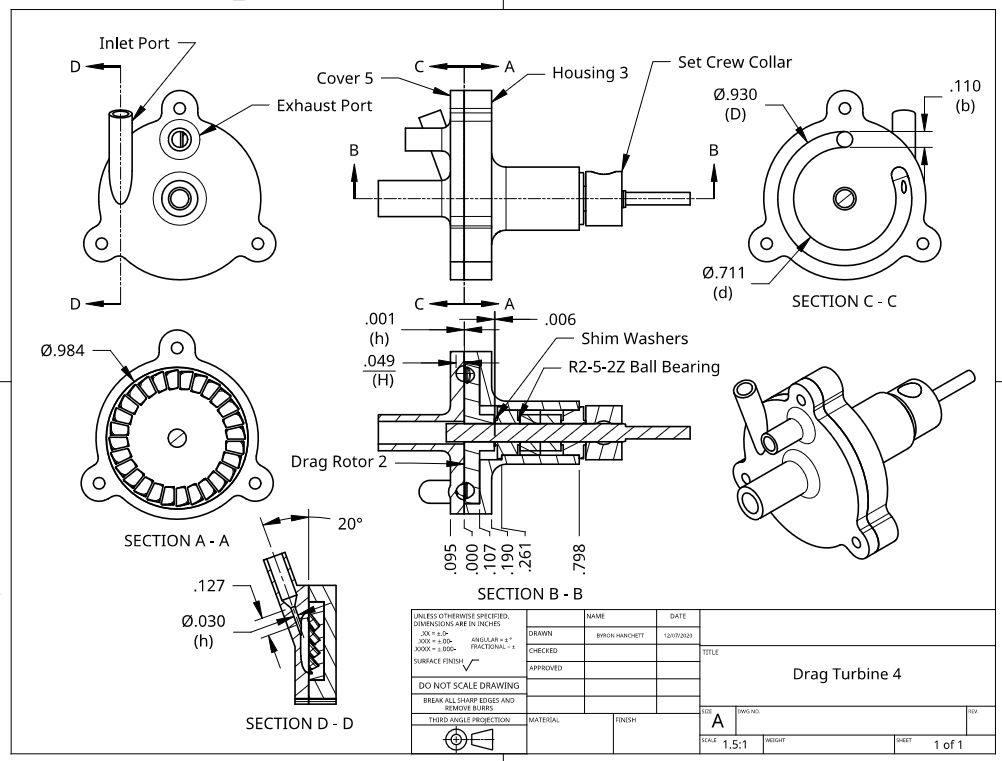

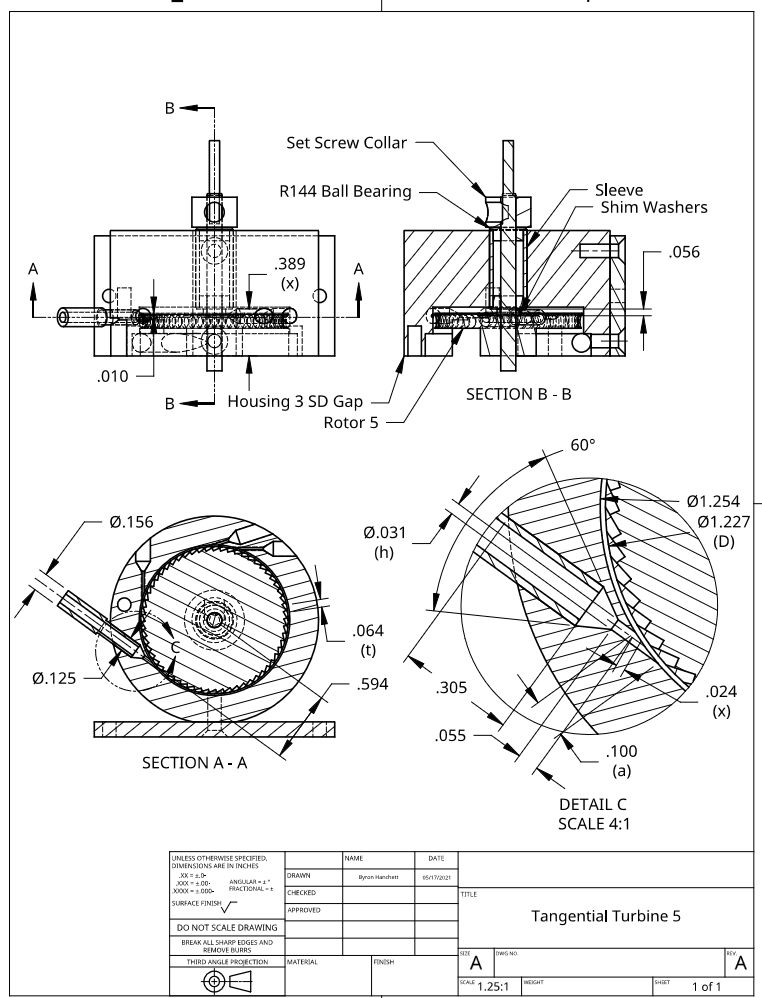

I ran Tangential Turbine 5, Axial Turbine 3N, and Drag Turbine 4 with the same ball bearings so that I can see the change in performance with the dental bearings when I try them. I already had run Drag Turbine 4 with the GWS EP 2508 propeller, but I ran it again to see if the ball bearings used in these last tests gave the same performance as in the previous test. The results were identical.

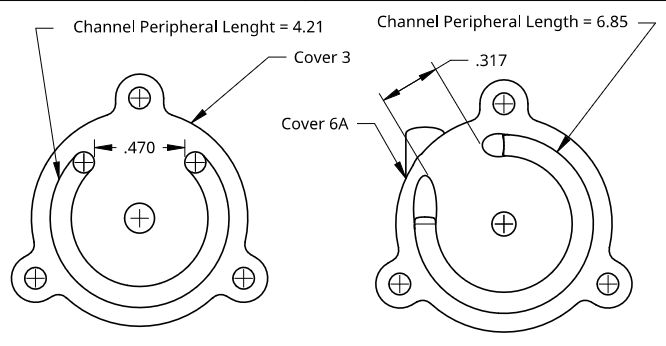

I received the dental ball bearings described in the last post and the items needed to make the reduction sleeve for the existing turbine housings. I will add the reduction sleeve to one of the turbine housings and run a test of the dental ball bearings.

The date shown for the test of Drag Turbine 6B should have been 4/9/2022.

Edited By Turbine Guy on 21/04/2022 15:21:44

Turbine Guy.