Model Turbines

Model Turbines

Home › Forums › Stationary engines › Model Turbines

- This topic has 599 replies, 28 voices, and was last updated 22 April 2025 at 21:59 by

Turbine Guy.

-

AuthorPosts

-

10 April 2021 at 14:50 #539010

Turbine Guy

Participant@turbineguyThank you for sharing your very well done video. I hope it will encourage others to show what they have done or plan to do with model turbines.

10 April 2021 at 17:06 #539024Turbine Guy

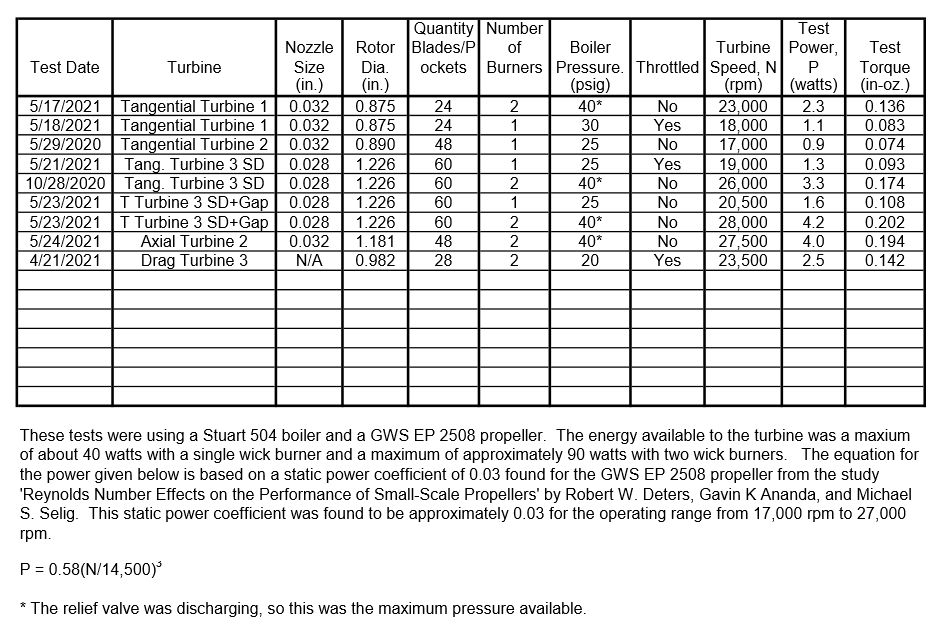

Participant@turbineguyI ran Drag Turbine 3 on steam from my Stuart 504 boiler with the GWS EP 2.5×0.8 propeller. I used the single wick burner from my Stuart Twin Drum boiler for heat so that the energy input would be the same as if I ran the much smaller Twin Drum boiler. The pressure gage had stopped working on the Twin Drum boiler and that is the reason I didn’t use it for the test. The tiny pressure gage on the 504 boiler is so small and has so few scale divisions that reading low pressures is almost a guess. The pressure stayed approximately constant at the lowest part of the gauge scale so was below 10 psig. The total time of the run was 7 minutes and 19 seconds to empty the boiler that had a carefully measured ½ cup of water added. The mass flow was approximately 2.1 lb/hr. The enthalpy drop for 10 psig saturated steam and atmospheric exhaust is approximately 40 btu/lb. With this mass flow and enthalpy drop, the available energy to the turbine was approximately 25 watts. The speed of the turbine remained constant at about 15,000 rpm for most of the run. The power required for the propeller running at 15,000 rpm is approximately 0.64 watts. I ran the turbine on air shortly after the run with steam to blow out any condensed moisture. The maximum speed running on air was approximately 17,000 rpm with a corresponding power of about 0.93 watts. The power running on air was lower than shown on the table of the 09/04/2021 post because of the Krytox GPL 105 oil I use when running on steam. This oil has very high viscosity at room temperature but is resistant to steam and works well at the higher temperatures. Like my impulse turbines, the drag turbine performed better at low pressures with air than with steam even though the steam had much more available energy. I’m not sure if this is a result of the loss of energy from condensing of the steam or the rotational losses spinning at high speed through wet surfaces.

To speed up the boiler reaching full temperature I used both of my wick burners at the start of the run and made a very short run with double the heat input. I had to remove the second wick burner almost immediately after the pressure was close to the boiler maximum of 45 psig since the turbine speed was climbing above its recommended maximum. It appeared that with the higher flow the Stuart 504 boiler is capable of, Drag Turbine 3 would make close to the 4.0 watts I obtained with the Tangential Turbine 3 using this boiler.10 April 2021 at 22:28 #539062Turbine Guy

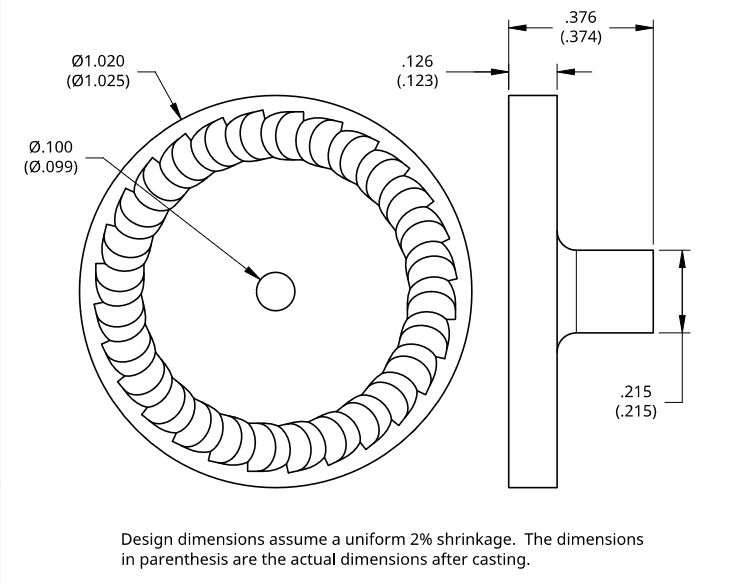

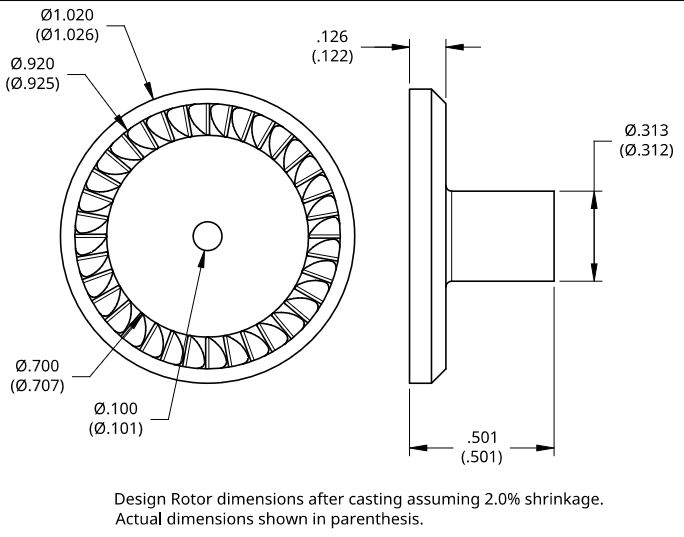

Participant@turbineguyMy Drag Rotor 4 casting finally arrived. The following picture shows a front view of it. The drawing below shows the design dimensions based on 2% shrinkage with the actual measured dimension show in parenthesis. The actual dimensions were very close to the design values again. The larger diameters had the maximum deviation. The 2% shrinkage appears to be a good assumption for these types and sizes of bronze castings from Shapeways. I will start the machining of Drag Rotor 4 on Monday. I have already finished the machining of the rotor shaft. I plan on lining up the casting in the 4 jaw chuck and then reaming the shaft bore with the reamer held in the collet holder using a very accurate collet. I will then remove the casting from the 4 jaw chuck and shrink it onto the rotor shaft. All of the remaining machining will be done with the rotor shrunk on the rotor shaft and the rotor shaft held in the very accurate collet and collet chuck mounted on the lathe head stock. This should ensure that the faces of the rotor are as perpendicular to the rotor shaft axis and as parallel with each other as I can make them. If anyone has a better way to ensure the highest accuracy, I would appreciate them giving it.

14 April 2021 at 12:58 #539683Turbine Guy

Participant@turbineguyI finished the machining on Drag Rotor 4 using the methods mentioned in the last post. The following picture shows the new rotor. I tried my first tests with Drag Turbine 4 but could not get a pressure above 2.5 psig even with the face of the rotor pressed against the face of the cover plate. I tried Drag Rotor 3 and the pressures was much lower than I was getting before. I checked for external leaks and couldn’t find any. I plugged the line going to the turbine inlet and turned the airbrush compressor on and the pressure immediately went up to the set pressure of 30 psig and stopped. I turned off the airbrush compressor and the pressure didn’t drop after several minutes. This confirmed that there was no leakage in the lines going to the turbine. I tried blocking the exhaust tube and the pressure only went up slightly. The one positive thing of this test was that the pressure didn’t change with the position of the rotor. I will give an update when I find what the problem is.

16 April 2021 at 19:24 #540096Turbine Guy

Participant@turbineguyI lapped the mating faces of the cover plate and the housing using an oilstone. The lapping removed enough material that I had to change the number of shims. I ran Turbine 3 again and the pressure was back to 4 psig but the maximum speed turning the GWS EP 2.5×0.8 propeller was only 14,500 rpm. After the test running on steam described in the post of 10/04/2021 the maximum speed running on air was 17,000 rpm with the turbine still hot. The power at 14,500 rpm is approximately 0.6 watts with this propeller and 0.9 watts at 17,000 rpm. The viscosity of the Krytox GPL 105 oil is high enough at the low temperatures running on air to lose approximately 0.3 watts with oil recently added. I found with the oil tests shown in the 13/03/2020 Post that this oil will run a long time when using air only and gradually have less resistance as the oil gets thinner from use. I ran Drag Turbine 4 again on air but was having contact with the rotor regardless of the number of shim washers. I lapped the face of Drag Rotor 4 like I had done with Drag Rotor 2 but still had interference with any number of shims. I was about to measure Drag Rotor 2 and Drag Rotor 4 and try to see where the clearance was less but dropped my electronic caliper and broke it. I ordered a new caliper that is scheduled to arrive next Monday. I will see if the new caliper helps me find what is wrong with Drag Rotor 4.

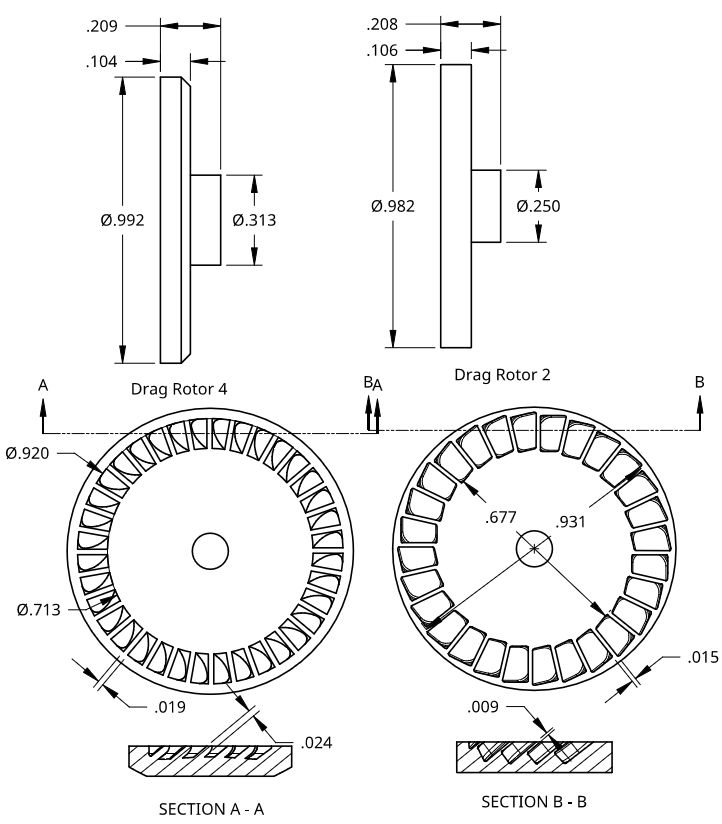

19 April 2021 at 18:43 #540561Turbine Guy

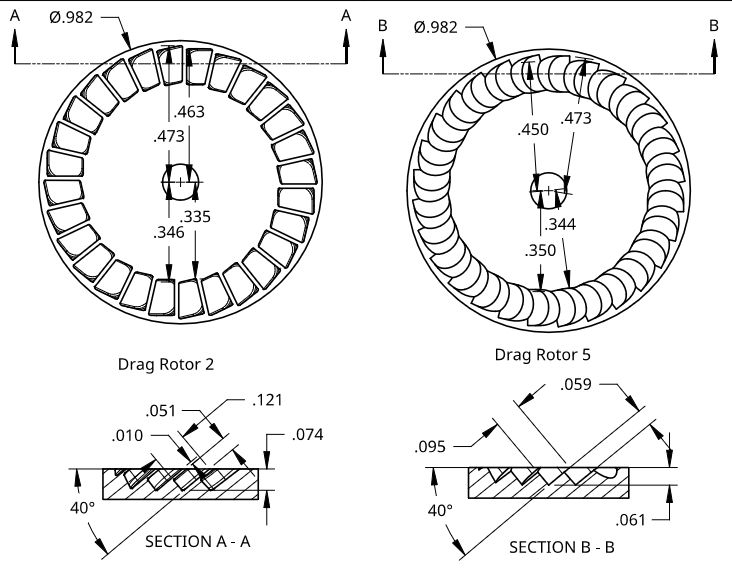

Participant@turbineguyI eliminated the binding problem on Drag Turbine 4 but the power is considerably lower than I get with Drag Turbine 3. I thought it was due to leakage but when I press the face of Drag Rotor 4 against the face of the cover plate the pressure only goes up slightly. The maximum pressure when running for Drag Turbine 3 is 4.0 psig and for Drag Turbine 4 is only 2.0 psig. The following drawing shows the existing dimensions of Drag Rotor 2 and Drag Rotor 4. I’m not sure if the reduction in channel size caused by the extra blades and thicker blades prevents the flow from circulating properly. The thicker blades are required to meet Shapeways minimum thickness requirements. The final dimensions of Drag Rotor 4 show the results of taking more off the face of the rotor to try to minimize leakage. Removing more from the face only increased the running pressure slightly, from about 1.5 to 2.0 psig.

1 May 2021 at 15:11 #542551Turbine Guy

Participant@turbineguyMy problems of getting more power from the drag turbines might be to a large extent due to the characteristics of small boilers and airbrush compressors. Neither of these does well in supplying energy at low pressures. I looked at the energy available to turbines as the pressure is lowered in the table shown in the 09/04/2021 post. The power of Drag Turbine 3 was much higher than Tangential Turbine 3 SD at very low pressures even though the available energy was almost the same. The drag turbine appears to need a large mass flow at a very low pressure to reach it’s potential. I have tried everything I can think of to increase the performance of Drag Turbine 3 without any success, so I plan to work on my impulse turbines again. I want to try using an insert like I described starting with the 07/04/2020 Post. I think I can make this work since I have a new nozzle without any of the obstructions that caused the failure in my first attempt.

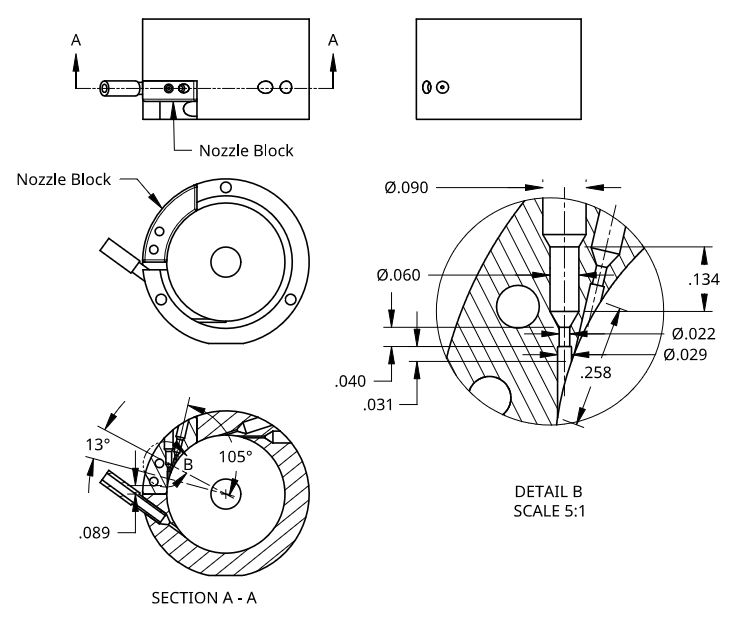

7 May 2021 at 19:12 #543749Turbine Guy

Participant@turbineguyAdding an insert as referenced in the last text gives the working gas a place to expand before contact with the rotor. This is important for higher pressures with resulting higher Mach numbers. I tried to get the Nozzle Block Casting shown in the following drawing from Shapeways since it would do the same thing as adding the insert. The file I sent to Shapeways the first time was rejected because it was too complex. The Nozzle Block I show below was initially accepted but then rejected. It appears that the very small steps in diameter at the exit of the nozzle are the problem. I was hoping I could get this made for two reasons. It would allow me to test the effect of the stepped nozzle without the possibility of destroying the existing nozzle. It would also allow me to test the increase in efficiency of using two nozzles or the effect of running at a higher pressure using just one nozzle. Unfortunately, the very tiny dimensions of small model turbines make meeting the requirements for casting difficult. I made a request to Shapeways to make the casting as submitted and I will take responsibility for the cleanup or failure if I cannot make it work. I have submitted a second design that I think eliminates aIl the problems but will require more machining after casting. I asked Shapeways to review the second design and if they agree that it can be made, add it to the order. The following drawing shows how I plan to open up the area in the existing Tangential Turbine 3 SD housing and mount the insert. All the dimensions of the Nozzle Block are after casting assuming 2% shrinkage. After I hear from Shapeways what they are willing to do, I will make an update to this thread.

Edited By Turbine Guy on 07/05/2021 19:16:16

13 May 2021 at 19:50 #544825Turbine Guy

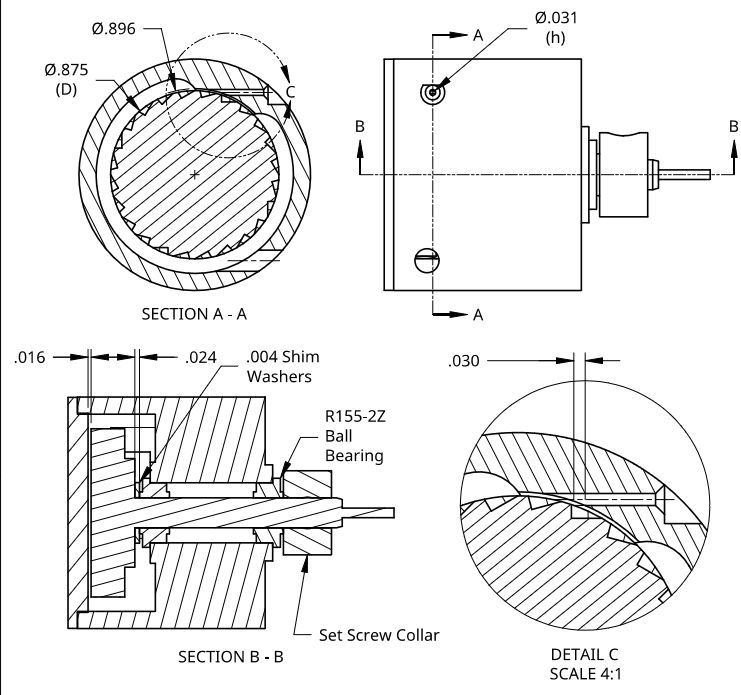

Participant@turbineguyI couldn’t come up with a design for the Nozzle Block Castings that Shapeways felt confident they could cast and would be easy for me to use. I thought about leaving a free space above the rotor for the gas to expand into as it goes supersonic. I reduced the clearance between the rotor OD and the housing to help reduce the blowby for the tangential turbines. This was one of the improvements I thought I made when I increased the rotor size from Rotor 1 to Rotor 2 in my first turbine. The following drawing shows the relatively large clearance I had in Tangential Turbine 1. With this clearance, the dimension 0.030 shown in Detail C is the shortest distance the gas would be able to travel after leaving the nozzle before contacting the rotor. This distance is close to what was used to space the rotor from the nozzle plate on Axial Turbine 2 for running on steam. Adding this space made quite an improvement in performance running on steam. To see if the extra clearance was a benefit running on steam for tangential turbines, I thought I would compare the performance of Tangential Turbine 1 that has this clearance with the performance of Tangential Turbine 2 that has very little clearance.

The maximum power for tests running on air with the GWS EP 2508 propeller taken from the table shown on the 10/10/2020 Post are 1.2 watts for Turbine 1 and 1.4 watts for Turbine 2. The maximum power for Turbine 2 running on steam at 25 psig pressure with the GWS EP 2508 propeller described in the 29/05/2020 Post is 0.9 watts for Turbine 2. The maximum power for Turbine 1 running on steam at 25 psig pressure with the GWS EP 2508 propeller in a test I ran yesterday is 1.5 watts. Turbine 2 lost 0.5 watts running on steam whereas Turbine 1 gained 0.3 watts running on steam. Turbine 1 was the first of my tangential turbines to actually gain in power running on steam at 25 psig at the low output of my smallest boiler.14 May 2021 at 16:25 #545026Turbine Guy

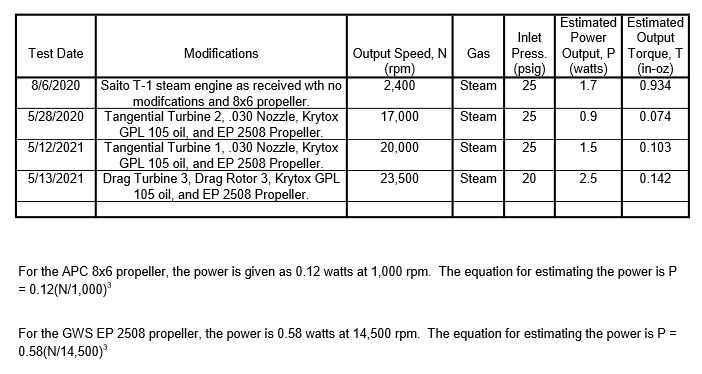

Participant@turbineguyI ran Drag Turbine 3 on steam from my Stuart 504 boiler with the GWS EP 2.5×0.8 propeller. I used two wick burners from my Stuart Twin Drum boiler for heat so that the energy input would be high enough to maintain a pressure of 20 psig. The pressure stayed approximately constant at around 20 psig for the entire run. The total time of the run was 8 minutes and 53 seconds to empty the boiler that had a carefully measured 3/4 cup of water added. The mass flow was approximately 2.64 lb/hr. The enthalpy drop for 20 psig saturated steam and atmospheric exhaust is approximately 63 btu/lb. Since I used the valve on the boiler to keep the pressure at 20 psig, the pressure at the turbine was less and so also the available energy. With this mass flow and enthalpy drop, the available energy to the turbine was less than 49 watts. The speed of the turbine remained constant at about 23,000 rpm for most of the run. The power required for the propeller running at 23,000 rpm is approximately 2.5 watts. I ran the turbine on air shortly after the run with steam to blow out any condensed moisture. The maximum speed running on air was approximately 15,500 rpm with a corresponding power of about 0.7 watts. The power running on air was lower than shown on the table of the 09/04/2021 post because of the Krytox GPL 105 oil I use when running on steam. This oil has very high viscosity at room temperature but is resistant to steam and works well at the higher temperatures. Unlike my impulse turbines, the drag turbine performed better at low pressures with steam than with air taking more advantage of the increased energy available. I updated the following chart adding the performance of Tangential Turbine 1 and Drag Turbine 3 running on steam. This did confirm that the drag turbine becomes more competitive with the tangential impulse turbines at low pressure and energy levels when there is sufficient mass flow.

15 May 2021 at 10:46 #545170AdrianR

Participant@adrianr18614Posted by Turbine Guy on 14/05/2021 16:25:29:Since I used the valve on the boiler to keep the pressure at 20 psig, the pressure at the turbine was less and so also the available energy. With this mass flow and enthalpy drop, the available energy to the turbine was less than 49 watts.

I don't understand why you kept the boiler pressure at 20PSI instead of opening the valve fully. If you had the valve fully open, would you not have been able to measure the pressure at the turbine and calculate the efficiency?

15 May 2021 at 12:32 #545193Turbine Guy

Participant@turbineguyPosted by AdrianR on 15/05/2021 10:46:16:Posted by Turbine Guy on 14/05/2021 16:25:29:Since I used the valve on the boiler to keep the pressure at 20 psig, the pressure at the turbine was less and so also the available energy. With this mass flow and enthalpy drop, the available energy to the turbine was less than 49 watts.

I don't understand why you kept the boiler pressure at 20PSI instead of opening the valve fully. If you had the valve fully open, would you not have been able to measure the pressure at the turbine and calculate the efficiency?

I had planned on running the test with the valve fully open but the pressure was so low that it could not be read on the small Stuart 504 boiler gauge. I don't use the large pressure gauge shown in previous posts when running on steam since it is recommended for lower temperatures. Interestingly, the speed went up as I closed the valve so I set the boiler pressure to what my smaller Stuart Twin Drum boiler runs at. I was using the bigger boiler because I thought the pressure gauge on the smaller boiler was not working.

15 May 2021 at 12:41 #545195Tim Stevens

Participant@timstevens64731Speed going up when you closed the valve is mirrored when you water the garden with a plain (no nozzle) hose. You can get the water to reach much further (ie with more power, and to move more force through more distance) by holding your thumb to partially obstruct the outlet.

Cheers, Tim

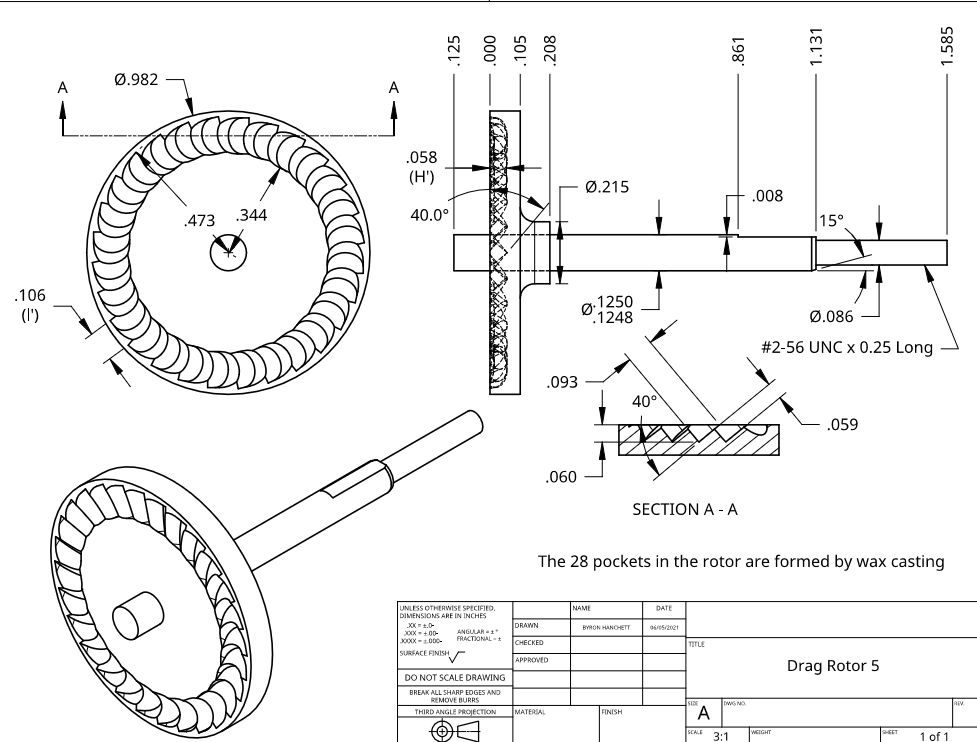

16 May 2021 at 20:03 #545507Turbine Guy

Participant@turbineguyI decided to try an open pocket type of drag rotor instead of using blades. The blades have to be very thin in the small turbines. Drag Rotor 2 was able to be cast with 0.010" thick blades, but I don't know if Shapeways would do this casting again since the blade thickness is less than the 0.024" minimum that would be applicable for the blades. When I made the blades thicker for Drag Rotor 4, the power dropped considerably. My success with the open pockets of the tangential turbines compared with the blades of the cast axial rotor makes me think this is worth trying. The following drawing shows the dimensions of Drag Rotor 2 with those of Drag Rotor 5 that I just ordered. The dimensions are the finished dimensions after casting and all machining. I tried to make the open pocket version as close to the version with blades as possible to get a good comparison of performance. While I wait on the new Drag Rotor 5 casting to arrive, I will look at the effects on performance when throttling the boiler. I would like to see if this improves the performance when running on steam for different pressures and energy inputs.

18 May 2021 at 19:43 #545788Turbine Guy

Participant@turbineguyI ran Tangential Turbine 1 on steam from my Stuart 504 boiler with the GWS EP 2.5×0.8 propeller. I used one wick burner from my Stuart Twin Drum boiler for heat. The single wick burner was able to supply enough heat to the Twin Drum boiler to hold a pressure of around 25 psig with a 0.029” nozzle throat diameter. When I opened up the nozzles of my turbines, the pressure could never reach the 25 psig with the single wick burner. The pressure was so low with the larger nozzles I thought that the pressure gage had quit working. I tested the pressure gage and found that it was okay. Using the single wick burner with the Stuart 504 boiler is not as efficient as with the smaller Twin Drum boiler because the larger boiler has so much more mass to heat up and so much more area to lose heat. The following picture shows the boilers side by side and the wick burner I used. I ran this test with the Stuart 504 boiler because it has a valve to control the discharge. I used the boiler valve to find the boiler pressure that gave the turbine its maximum speed. The pressure stayed approximately constant at around 35 psig for a maximum speed of approximately 18,000 rpm. The power required for the propeller running at 18,000 rpm is approximately 1.1 watts. The speed and power dropped off for any pressure above or below 35 psig. The throttle valve will be necessary for running any model that can pull the steam out of the boiler too easily. Throttling the steam allows the boiler to add more energy by working at a higher pressure. The steam downstream of the valve is at a lower pressure but dryer. The dryer steam partially offsets the loss in available energy to the turbine after throttling. Even with the extra losses using the larger boiler with only one wick burner, Tangential Turbine 1 was able to put out almost as much power with steam than with air using my airbrush compressor (1.1 watts vs 1.2 watts).

21 May 2021 at 12:27 #546160Turbine Guy

Participant@turbineguyI ran two tests using Tangential Turbine 3 SC, the GWS EP 2508 propeller, and the Stuart Twin Drum boiler a while ago that I didn’t publish because I could not determine why the results were so bad. The maximum speed the propeller reached in both tests was approximately 7,500 rpm. The power required to turn the propeller at that speed is approximately 0.08 watts. I was able to turn the propeller at a speed of 11,000 rpm using my airbrush compressor to blow out the moisture immediately after each run. The turbine was still hot enough that the Krytox GPL 105 oil allowed the higher speed. The power required by the propeller for a speed of 11,000 rpm is approximately 0.25 watts. Part of the low performance of these tests was due to the very viscous oil. After finding out that the pressure gauge was still working, I thought the main problem was the very low energy in the steam. I ran a test yesterday similar to the one I described in the last post. I ran this test with the Stuart 504 boiler because it has a valve to control the discharge. I used the boiler valve to find the boiler pressure that gave the turbine its maximum speed. The pressure stayed approximately constant at around 25 psig for a maximum speed of approximately 18,000 rpm. The power required for the propeller running at 18,000 rpm is approximately 1.1 watts. The speed and power dropped off for any pressure above or below 25 psig. Just like the last post, the power increased with throttling. Tangential Turbine 3 SC had the same power running on steam from the Stuart 504 boiler with one wick burner as Tangential Turbine 1 even though it’s performance on air using the airbrush compressor is quite a bit higher (2.6 watts vs 1.2 watts). I think this confirms that extra space for the gas to expand before contacting the rotor is needed for converging only nozzles running at high energy levels. It also confirmed that a valve on the boiler is needed for running the turbines if the nozzle bore size is too large.

Edited By Turbine Guy on 21/05/2021 12:31:00

21 May 2021 at 18:32 #546207Turbine Guy

Participant@turbineguyI ran one more test of Tangential Turbine 3 SC with everything the same as in the last two posts except I replaced the ball bearings in this turbine with the ball bearings used in the last test of Tangential Turbine 1. Since I am comparing the performance of these two turbines, I thought I should make sure the ball bearings are in the same condition. Now I can compare the performance of these two turbines with the same boiler, burner, oil, throttled flow, and ball bearings. I ran Tangential Turbine 3 SD on steam from my Stuart 504 boiler with the GWS EP 2.5×0.8 propeller and one wick burner. I used the boiler valve to find the boiler pressure that gave the turbine its maximum speed. The pressure stayed approximately constant at around 25 psig for a maximum speed of approximately 19,000 rpm. The power required for the propeller running at 19,000 rpm is approximately 1.3 watts. The speed and power dropped off for any pressure above or below 25 psig. The change in performance of Tangential Turbine 3 SD using the ball bearings used in the test of Tangential Turbine 1 was a gain in power of approximately 0.1 watts, so the ball bearings had only a minor effect on the outcome.

24 May 2021 at 16:29 #546850Turbine Guy

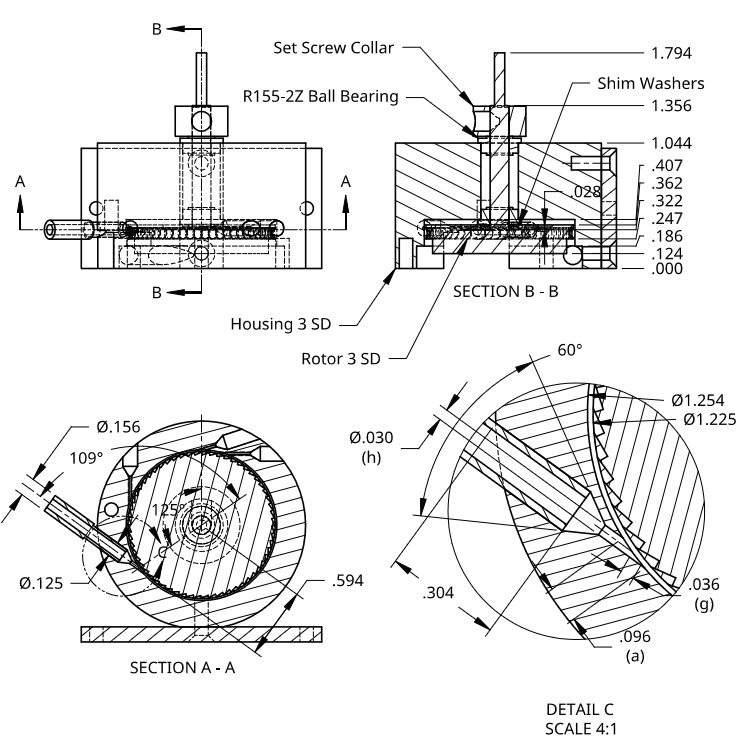

Participant@turbineguyI decided to go ahead and try enlarging the housing diameter that the rotor fits under in Tangential Turbine 3 SD. The following drawing is an update to the drawing shown in the 27/09/2020 Post. I increased the diameter from 1.230” to 1.254” to provide a space for the gas exiting the nozzle to expand before contacting the rotor. The dimension 0.036” (g) is the minimum distance the gas travels before contacting the rotor. I thought that opening this gap for the higher energy flows would reduce the power for lower energy flows. I ran several tests before opening the gap and compared the results with those after opening the gap. The next post will show the table I created to compare the results.

24 May 2021 at 16:50 #546853Turbine Guy

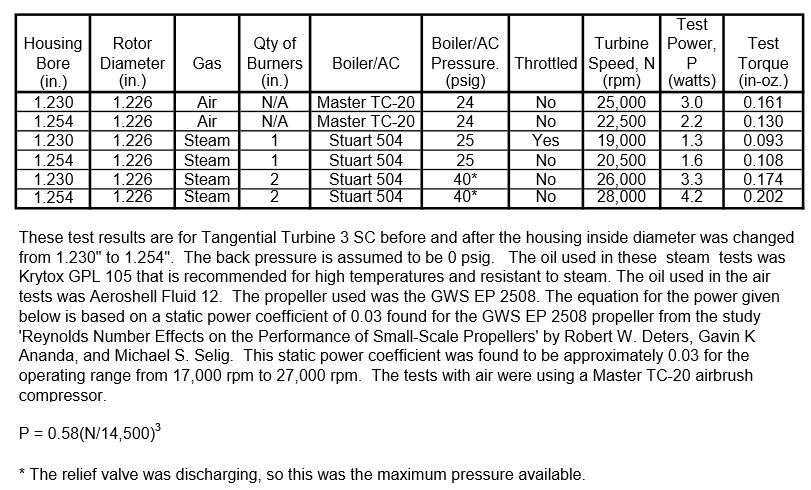

Participant@turbineguyThe following table shows the results of the testing I described in the previous post. The power decreased 0.8 watts running on air at 24 psig from my airbrush compressor. This is the lowest input energy and needs the smallest gap. The power increased 0.3 watts running on steam from the Stuart 504 boiler with 1 burner. This is a slightly higher level of input energy and requires a little more gap. The power increased 0.9 watts running on steam from the Stuart 504 boiler with 2 burners. These tests indicate that if you plan to run on a low energy source like a airbrush compressor the gap should be kept small. If you plan on running on steam the gap of 0.036” would be right for pressures up to 50 psig. These results are using a convergent only nozzle with a throat diameter of 0.030”.

26 May 2021 at 14:13 #547217Turbine Guy

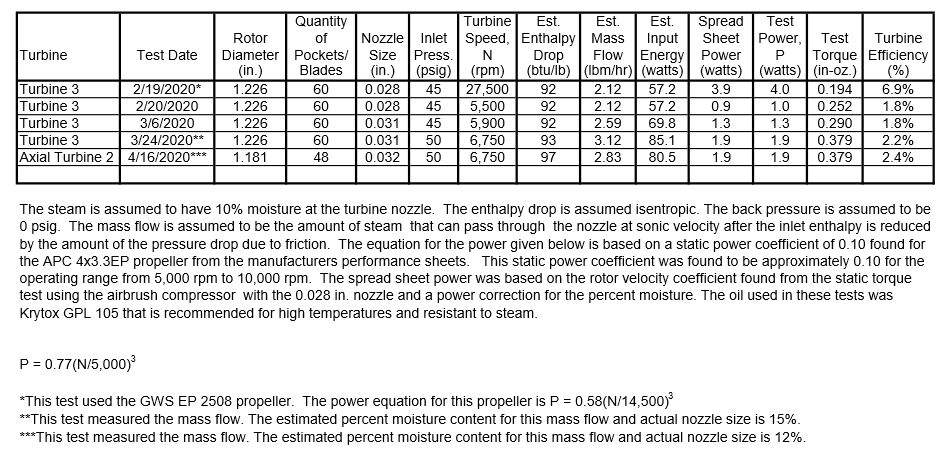

Participant@turbineguyAfter running the last few tests, I was curious how the torque in the table shown below (copied from the post of 30/04/2020) could be so large. I quit testing the turbines on steam at the higher pressures using the GWS EP 2508 propeller because I thought with this much torque, the speed would get too high. I ran the following test with Axial Turbine 2 using the GWS EP 2508 propeller, the Stuart 504 boiler, two burners, the same bearings of the last few tests, and with the Krytox GPL 105 oil. The maximum speed obtained was 27,500 rpm at a pressure of approximately 40 psig. The throttle valve was fully open and the boiler relief valve was continuously releasing a small amount of steam. The amount of steam released in this test was quite a bit less than the test in the last post. The nozzle in Axial Turbine 2 is larger than the nozzle in Tangential Turbine 3 SD (0.032” vs 0.030"

so this test had more mass flow than the last test. The power required by the propeller at a speed of 27,500 rpm is approximately 4.0 watts and the corresponding torque is 0.194 in-oz. This power and torque appears to be correct since they are close to the power and torque of some of Werner Jeggli’s test results of this rotor. Werner has a much better testing setup as explained in the 10/09/2020 Post. I ran a second test with everything the same except using the APC 4×3.3 EP propeller. The maximum speed obtained was 5,500 rpm. The power required by this propeller at a speed of 5,500 rpm is 1.0 watts and the corresponding torque is 0.252 in-oz. These values of power and torque indicate the test results in the following table are not correct. I was having trouble getting good readings of speed when running on steam with my first propeller tachometer and changed to a type that is less effected by the steam blowing around the propeller. I will correct this table to show the latest test results.

so this test had more mass flow than the last test. The power required by the propeller at a speed of 27,500 rpm is approximately 4.0 watts and the corresponding torque is 0.194 in-oz. This power and torque appears to be correct since they are close to the power and torque of some of Werner Jeggli’s test results of this rotor. Werner has a much better testing setup as explained in the 10/09/2020 Post. I ran a second test with everything the same except using the APC 4×3.3 EP propeller. The maximum speed obtained was 5,500 rpm. The power required by this propeller at a speed of 5,500 rpm is 1.0 watts and the corresponding torque is 0.252 in-oz. These values of power and torque indicate the test results in the following table are not correct. I was having trouble getting good readings of speed when running on steam with my first propeller tachometer and changed to a type that is less effected by the steam blowing around the propeller. I will correct this table to show the latest test results.Edited By Turbine Guy on 26/05/2021 14:17:02

29 May 2021 at 19:54 #547717Turbine Guy

Participant@turbineguyBecause I have shown tests performed with my biggest boiler (Stuart 504) and smallest boiler (Stuart Twin Drum), the test results are a little misleading. All the tests with the Stuart Twin Drum boiler were made without a throttle valve on the boiler. As I have recently found, a throttle valve is needed in some cases to get the best performance. Since I am now doing all my testing on steam with the Stuart 504 boiler but sometimes using just one burner to simulate power from a small boiler, I will show the number of burners used and if the flow was throttled. I also checked the nozzle size used for the last few tests and show them in the new table shown below.

4 June 2021 at 16:39 #548313Turbine Guy

Participant@turbineguyI received the casting of Drag Rotor 5 described in the 16/05/2021 post from Shapeways. The following photo shows the face of the rotor. I hope you can see from the photo that Shapeways was able to make the open pockets very close to what was in the step file I sent them. The edges are sharp and the surfaces pretty smooth. To use the overlapping pockets in a drag turbine, I need to force the gas in the direction it flows down the channel. The overlapping of the pockets results in the center of the pocket having a clearance from the face of the rotor. This clearance will increase the leakage unless the gas has to reverse its direction to move toward the exhaust port. I will show in the next post the cover plate I designed to force the flow to move in the right direction. This is something I think will increase the performance with the other drag rotors.

4 June 2021 at 20:03 #548344Turbine Guy

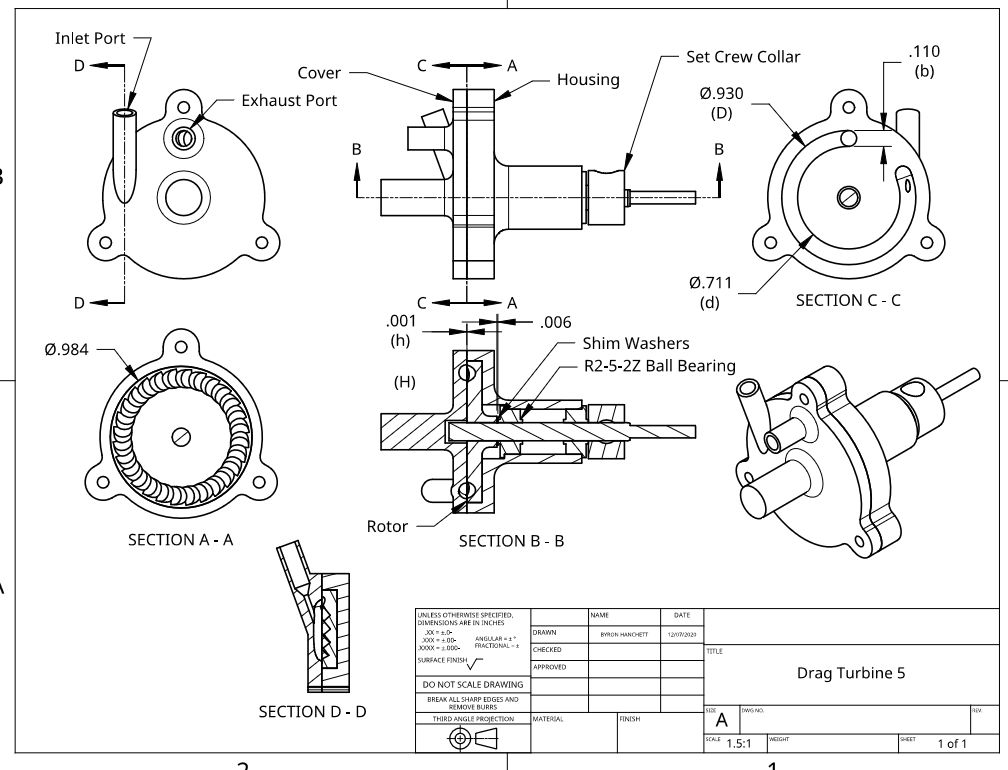

Participant@turbineguyThe following drawing of Drag Turbine 5 shows the new Cover 5 described in the last post. Sections C-C and D-D show the converging nozzle that has been added to the inlet and the direction of the flow. This and Drag Rotor 5 are significant enough changes to be treated as a new turbine. I am hoping that starting the flow in the correct direction will decrease the leakage and help get the corkscrew type of flow started. I also believe that there will be additional torque added by the impact of the high velocity inlet flow contacting the rotor pockets. I expect that there will be an optimum throat diameter of the inlet nozzle for each gas supply source (boiler or air compressor). I also think that Cover 5 will increase the performance when used with my other drag rotors. I have ordered the casting for Cover 5 from Shapeways and it has been accepted for production and given an expected time for delivery of the end of this month.

7 June 2021 at 19:42 #548751Turbine Guy

Participant@turbineguyI measured the actual dimensions of Drag Rotor 5 Cast and added them in parenthesis to the following drawing of the design dimensions assuming 2% shrinkage. The assumed shrinkage appears to be about right for this size and shape. I finished the machining of Drag Rotor 5 and show a photo and a drawing showing the finished dimensions in the next post.

Edited By Turbine Guy on 07/06/2021 19:50:49

7 June 2021 at 19:52 #548752 -

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Stationary engines › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Scam email

Started by:

Ian McVickers in: General Questions

- 16

- 22

-

9 May 2025 at 19:42

duncan webster 1

-

S&B Sabel lathe quick change tool post

Started by:

gerry45 in: Beginners questions

- 2

- 2

-

9 May 2025 at 19:37

Clive Foster

-

What size gear cutter for gear

1

2

Started by:

David George 1

in: Help and Assistance! (Offered or Wanted)

David George 1

in: Help and Assistance! (Offered or Wanted)

- 18

- 30

-

9 May 2025 at 19:24

Pete Rimmer

-

bolts harness and head shearing?

Started by:

jon hill 3 in: Related Hobbies including Vehicle Restoration

- 13

- 15

-

9 May 2025 at 19:06

bernard towers

-

Stuart Twin Victoria (Princess Royal) Mill Engine

1

2

…

50

51

Started by:

Dr_GMJN in: Work In Progress and completed items

- 33

- 1,262

-

9 May 2025 at 18:35

Dr_GMJN

-

Mystery Object found in FE College

Started by:

Master of none in: The Tea Room

- 3

- 4

-

9 May 2025 at 17:54

larry phelan 1

-

Myford Super-7 chuck – unacceptable run-out??

Started by:

flatline in: Manual machine tools

- 8

- 18

-

9 May 2025 at 17:40

old mart

-

FreeCAD v1.0 tutorials

1

2

Started by:

Michael Gilligan

in: CAD – Technical drawing & design

Michael Gilligan

in: CAD – Technical drawing & design

- 11

- 36

-

9 May 2025 at 17:30

Michael Gilligan

Michael Gilligan

-

Comm Ads

Started by:

bernard towers in: Website Questions, Comments, and Suggestions

- 3

- 9

-

9 May 2025 at 14:44

Hugh Stewart-Smith 1

-

Countersinking carbon fibre sheet with my Sieg CNC Mill

Started by:

Sarah F in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 6

- 15

-

9 May 2025 at 12:41

Sarah F

-

Adaptation of the Proxxon Milling machine

1

2

3

Started by:

Graham Meek in: Manual machine tools

- 13

- 62

-

9 May 2025 at 12:16

Graham Meek

-

Building Bernard Tekippe’s Precision Regulator

1

2

3

4

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 12

- 85

-

9 May 2025 at 12:13

Michael Gilligan

Michael Gilligan

-

connectors for NEMA17 motors

Started by:

Roger Hart in: General Questions

- 3

- 5

-

9 May 2025 at 11:51

John Haine

-

Clarkson T&C Grinder

Started by:

Ian Owen NZ in: Manual machine tools

- 5

- 18

-

9 May 2025 at 09:25

renardiere7

-

Tasteless advertising?

Started by:

Mike Hurley in: Website Questions, Comments, and Suggestions

- 8

- 8

-

9 May 2025 at 07:46

Graham Titman

-

LMS 2F Experiences

Started by:

Bryan Cedar 1 in: Locomotives

- 8

- 12

-

9 May 2025 at 07:16

Diogenes

-

Kia Ora from the bottom of the world. Tool hoarder & enthusiast.

Started by:

gimme72 in: Introduce Yourself – New members start here!

- 8

- 25

-

8 May 2025 at 22:51

Nigel Graham 2

-

What Did You Do Today 2025

1

2

…

4

5

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 28

- 108

-

8 May 2025 at 19:42

Diogenes

-

Purpose of pivot on carburettor linkage ? ?

Started by:

Alan Donovan in: Help and Assistance! (Offered or Wanted)

- 5

- 12

-

8 May 2025 at 19:03

Howard Lewis

-

Half Scale 1/4HP A J Weed Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 4

- 21

-

8 May 2025 at 18:40

JasonB

JasonB

-

Photos

Started by:

petro1head in: Website Questions, Comments, and Suggestions

- 7

- 17

-

8 May 2025 at 17:35

Colin Bishop

Colin Bishop

-

Help needed to price a Myford lathe going for sale

Started by:

Mick Durkin in: Help and Assistance! (Offered or Wanted)

- 2

- 3

-

8 May 2025 at 17:30

Mick Durkin

-

Oilite bush sizes

Started by:

Nick Taylor 2 in: Beginners questions

- 13

- 25

-

8 May 2025 at 11:02

Peter_H

-

Rain Gutter Power

Started by:

Michael Gilligan

in: Suggested Online Resources

Michael Gilligan

in: Suggested Online Resources

- 8

- 22

-

8 May 2025 at 09:54

duncan webster 1

-

Lathe improvements?

1

2

…

4

5

Started by:

Niels Abildgaard in: Manual machine tools

- 23

- 122

-

8 May 2025 at 09:23

Niels Abildgaard

-

Scam email

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Scam email

- S&B Sabel lathe quick change tool post

- What size gear cutter for gear

- bolts harness and head shearing?

- Stuart Twin Victoria (Princess Royal) Mill Engine

- Mystery Object found in FE College

- Myford Super-7 chuck – unacceptable run-out??

- FreeCAD v1.0 tutorials

- Comm Ads

- Countersinking carbon fibre sheet with my Sieg CNC Mill

so this test had more mass flow than the last test. The power required by the propeller at a speed of 27,500 rpm is approximately 4.0 watts and the corresponding torque is 0.194 in-oz. This power and torque appears to be correct since they are close to the power and torque of some of Werner Jeggli’s test results of this rotor. Werner has a much better testing setup as explained in the

so this test had more mass flow than the last test. The power required by the propeller at a speed of 27,500 rpm is approximately 4.0 watts and the corresponding torque is 0.194 in-oz. This power and torque appears to be correct since they are close to the power and torque of some of Werner Jeggli’s test results of this rotor. Werner has a much better testing setup as explained in the