Posted by duncan webster on 16/02/2019 20:17:16:

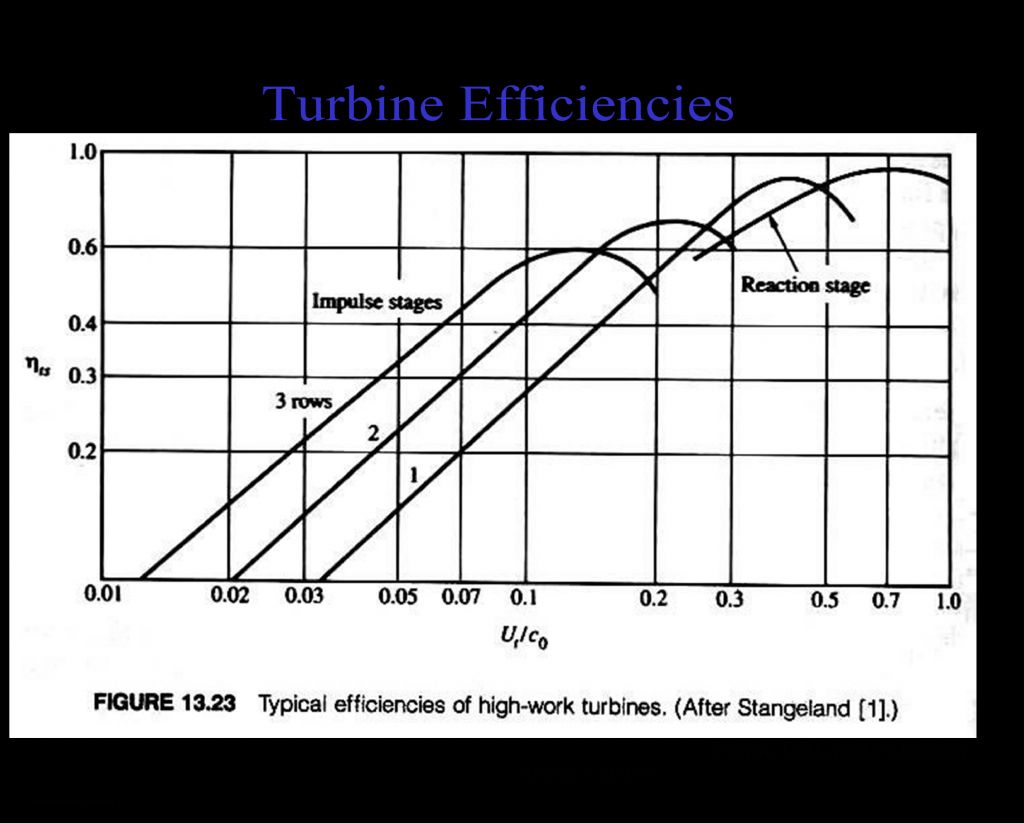

The 1200 rpm is nowhere near fast enough for a 12" diameter 2 stage Curtis. 12000 might be nearer the mark.

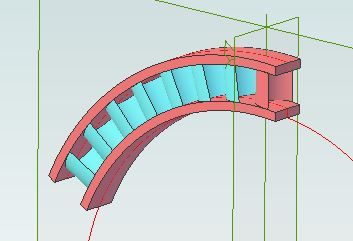

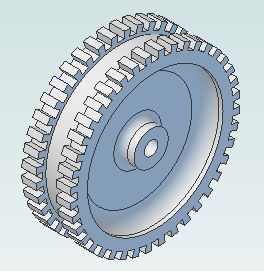

The passage through the blades should be parallel for an impulse turbine, one can't achieve this with blades pressed from thin sheet, and they should be close pitch

Edited By duncan webster on 16/02/2019 20:17:30

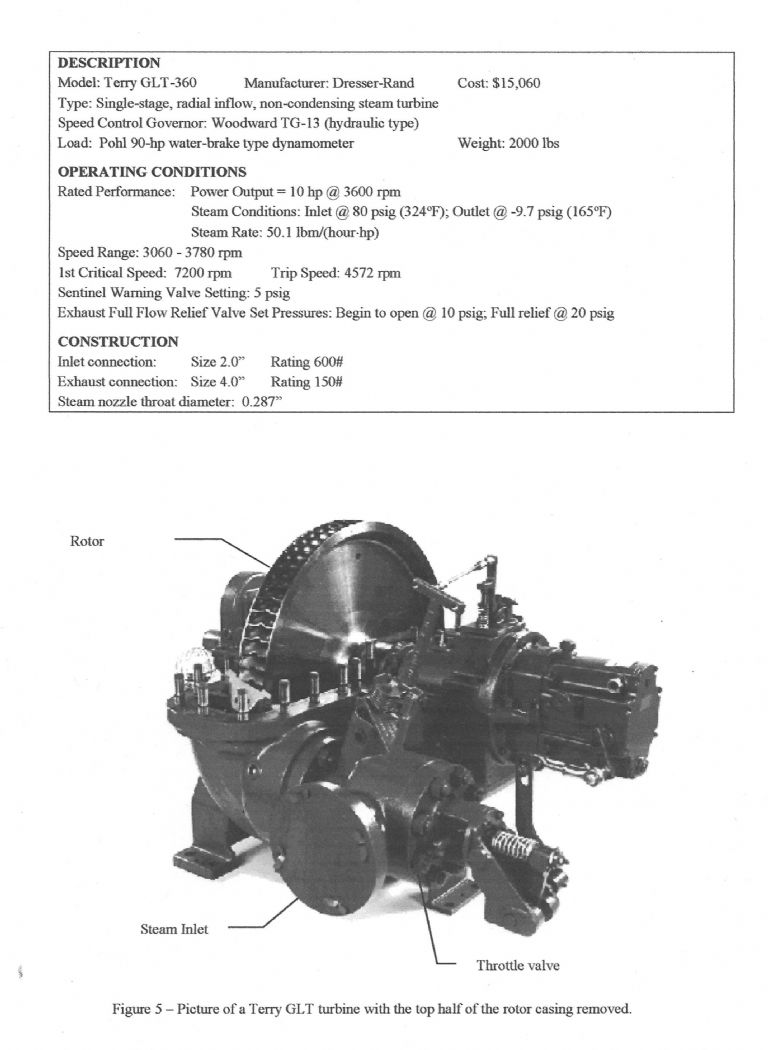

Actually Duncan, not to rain on your parade, but the 1200 rpm is very real.

Coppus manufactured radially split 2 row turbines in wheel diameters from 9" to 23", specifically designed for hp ranges from fractional to 1000bhp, at speeds anywhere from 600 to 6600 rpm. As well as most typical speeds in the 3600 rpm range, low speed direct drive applications were quite common, such as lube oil pumps, boiler draft fans and feed pumps. While the lower speed applications were not very thermally efficient, the exhaust steam was typically used to feed a deaerator/feed water heater instead of using a PRV, thereby recovering the residual waste heat. I know this for fact, as I worked with literally hundreds of them over the course of 40+ years (as well as turbines manufactured by Elliot, Worthington, ABB & others).

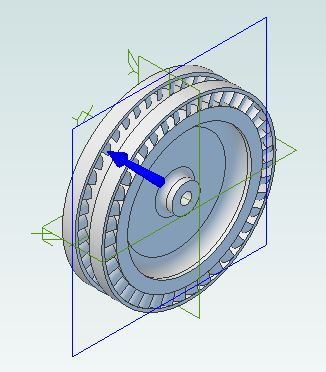

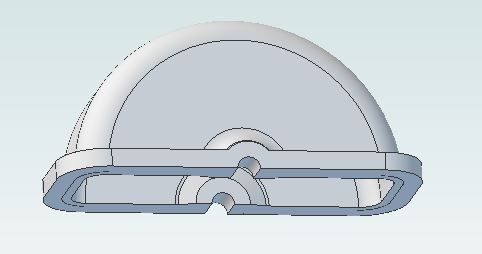

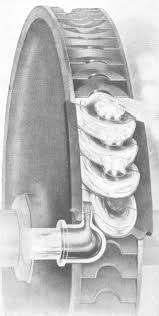

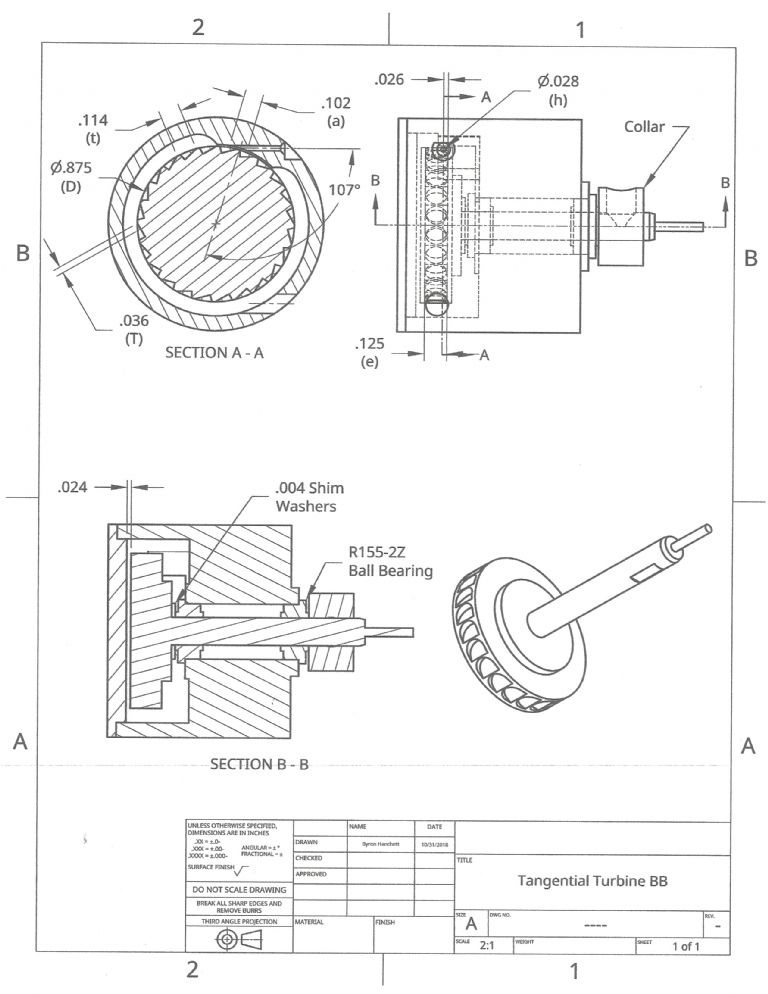

I am aware that a formed bucket is not an ideal design – if you read my earlier posts, you will note that I stated that in the real world they are broached out of a steel alloy. Using a formed bucket is a compromise, as broaching buckets in the very small size for my scale model is not realistic. That said, I can very accurately produce a nozzle block with multiple parallel convergent/divergent steam nozzles whose flow is parallel and feeds the wheel at the correct angle. As designed, the blades will be deliberately wider than the final dimension, with post assembly machining to final dimension providing a knife edge.

Tim

Edited By Tim Taylor 2 on 17/02/2019 01:30:05

Turbine Guy.