On

13 January 2025 at 20:14 JasonB Said:

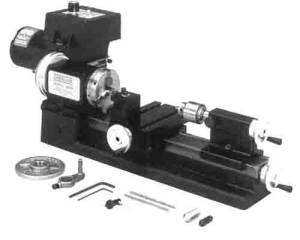

The Taigturn is like the Sherline chucker lathes for small production, if you want to drill something you hold the drill in one of many toolposts.

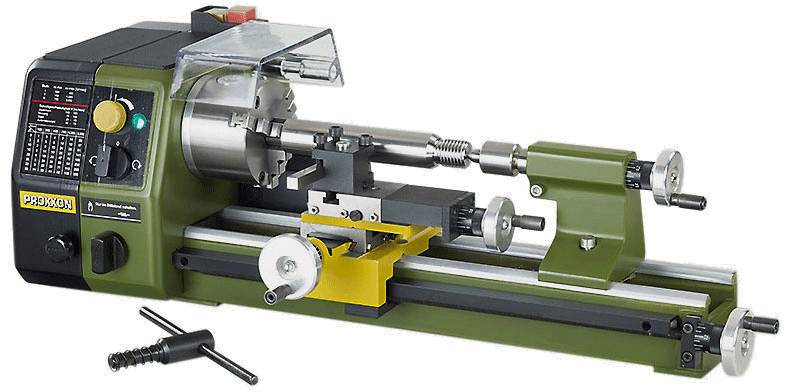

If it were me I would go with the Sherline as it has the larger capacity with the riser blocks, C package will give you screwcutting or consider a small ELS so you get power feed too. Don’t need to limit yourself to watch making, go look at the work of Chris Ruby over on MEM to see what they can do in the right hands. Even my Unimat 3 was capable of making a Stuart 10 size engine and could easily handle all the small engines I have made on the bigger machine or do mods on RC models if thats your thing.

I think also Taig/Peatol has optional riser blocks. Sherline seems to be more expensive for similar configuration. On the other hand it is available in many places, even here in Romania.

On

13 January 2025 at 20:49 Bazyle Said:

Is it only sometimes working away from home? Will you still have the big lathes? Could you join a club/maker group etc to access machines. Most of the time making something isn’t using the lathe. The supporting hand tools will also weigh a lot. A portable bench with vice would support a lot of activity.

I’ll still have the garage with all machines. But I’m moving with my family to Barcelona. We have no plans for how long we’ll stay there. It could be only months or years. And most likely well live in an apartment. To rent a house would cost a fortune there. So it will be a living room workshop. No more welding, cutting 6 meter pipes with TCT saw, angle grinder fun or furnace project. Or maybe I could still heat small parts on the beach with a large Fresnel lens and quench them in the sea 🙂

I didn’t found so far a club or maker group there. But I’ll dig deeper after I’ll arrive. Another city on our whish list was Eindhoven. It has way more jobs that Barcelona and everybody speaks English. There I found a very nice club where Philips donated lathes, mills and other machines. With 35 euro/year you can have access to everything! But my wife didn’t liked the weather. And we both fell in love with Spain.

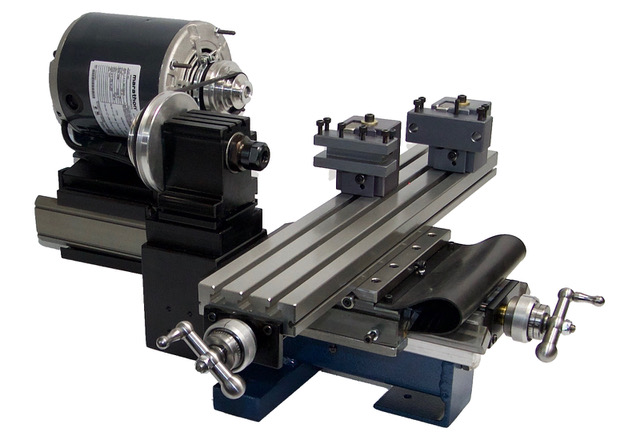

But now if I’m thinking better the weight limit doesn’t make much sense. Indeed the rest of the tools would quickly add more weight. In the past when we lived abroad we rented space on trucks to move stuff. Probably we’ll do this again. Still I would not bring the 1.5 ton mill but something up to 50-60kg should be fine.

Sonic Escape.

Sonic Escape.