Hello Paul,

Only too glad to help, I was an owner after my father died for about 20 years which gave me a familiarisation time from when he bought it in 1945 of about 40 years.

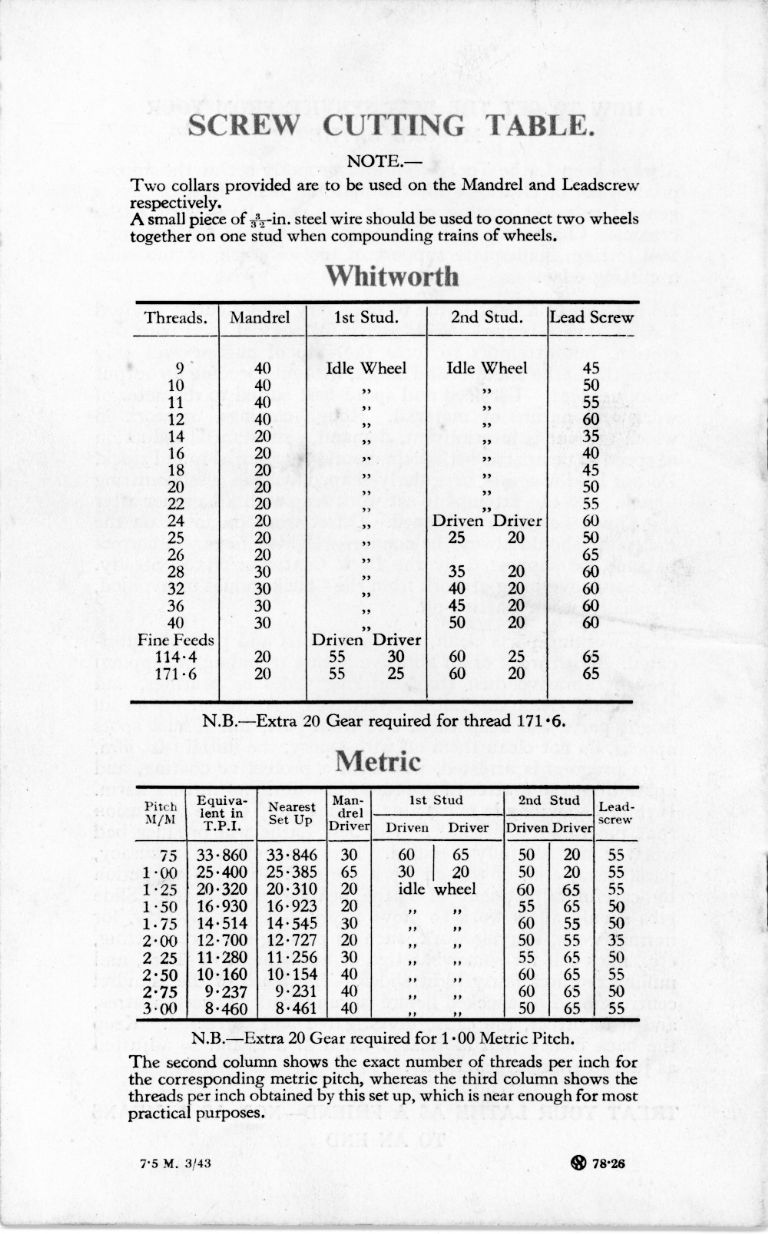

The thing to bear in mind with gearing is that a simple chain of gears, all in line with each other, is that the ratio is determined by the first and last gear in the chain; just as would be the case of a pulley system with the belt linking the two pulleys. The 'belt' in that case is idler gears that merely provide the link and can be any size for convenience.

Compound gearing however, examples are in the fine feed and metric table I sent, alter the overall gearing ratio.

Get a pencil and paper and lay out such a chain with the driver wheels on the top line, divided by driven wheels on the bottom line, multiply the result by 1divided by 8 [the leadscrew tpi] for imperial or 1 divided by 8 times 25.4 for metric to get the resulting pitch of the thread produced.

Returning to your original question, cutting an 8 tpi thread. Before you actually cut metal I have always found it useful to do an 'air-cut' first just to be sure you are following the expected track and that all the subsequent cuts to depth are in phase.

Please get in touch if I can be of further help

Brian

Brian Wood.