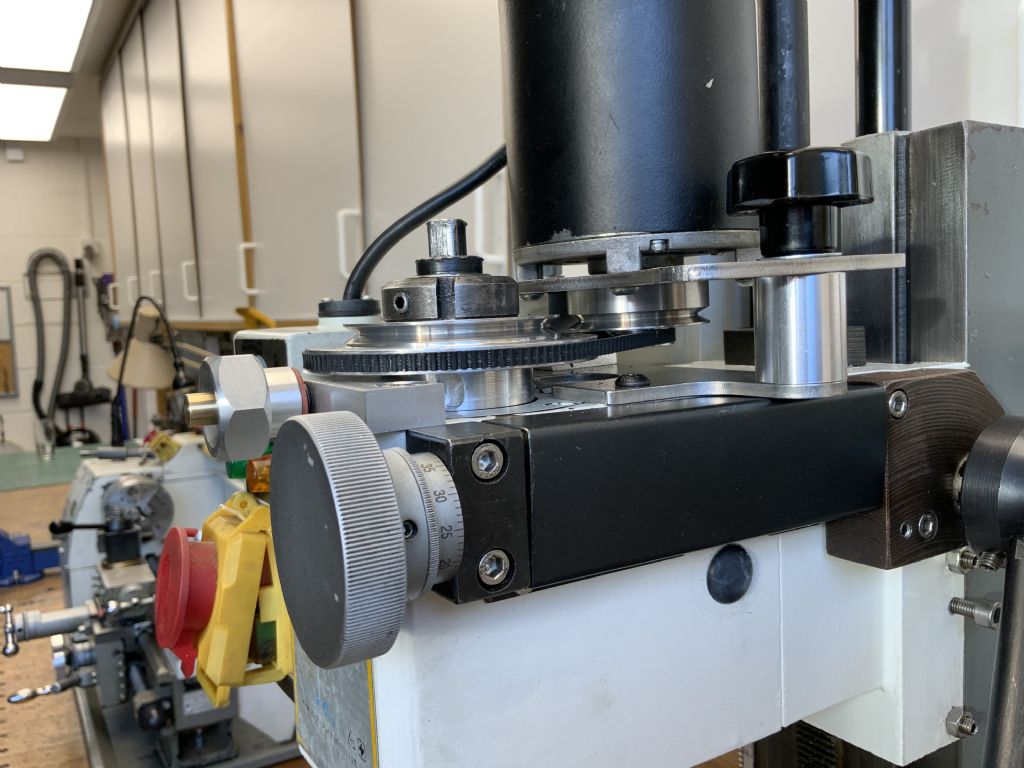

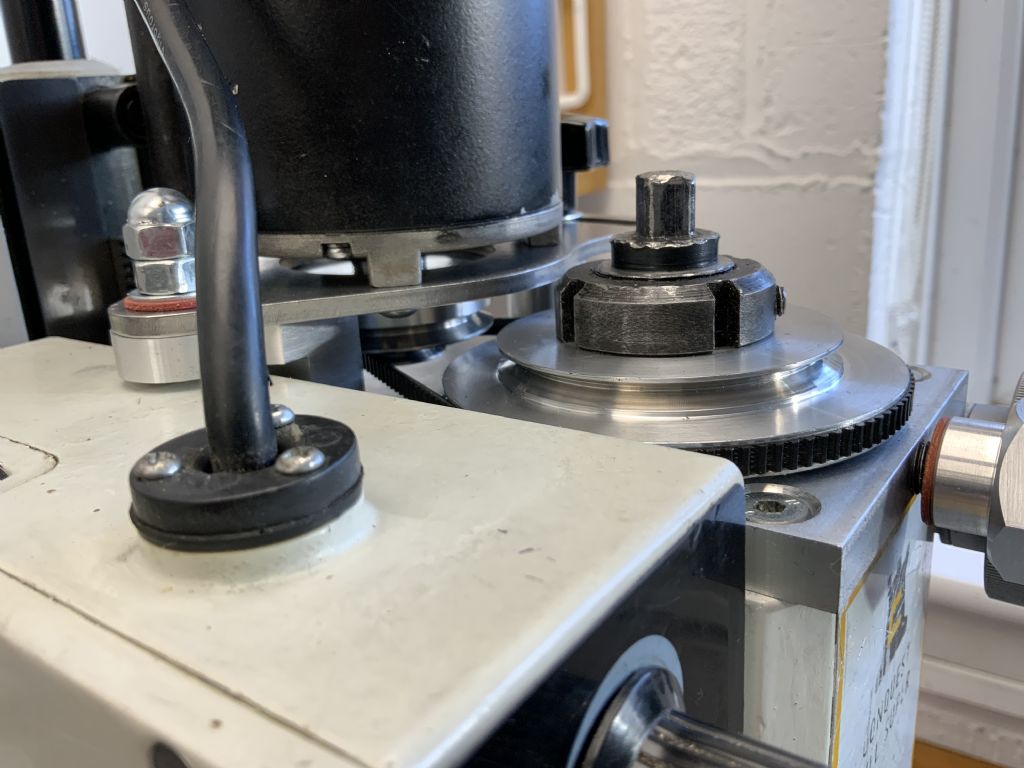

I have a Warco WM16 gearhead mill and was also considering taking a punt on this Turkish supplier of belt conversions http://www.mbbilici.com/

I would be interested to learn from anyone that has purchased a conversion unit, what was the actual customs / VAT charge on import?

Has anyone fitted that particular conversion to an actual WM16? Do they have pictures or a description they could share? Looking at the picture of the unit, I cant grasp how it is fitted to a WARCO 16 other than somehow over the spindle on top of the existing Hi/Lo gear stack. Does this mean that the motor cover / speed pick up may have to be modified to re-fit? Is there still a noise issue with the gears (presumably less as no longer under load).

Can this mod be simply carried out with the head left in place on the machine? Or does it actually involve pressing out of bearings etc. to remove the intermediate gear shaft and/or Hi/Lo spindle gears? (ie. almost complete dismantling?).

From the warco manual, if the shafts are pressed out of the head casting, will this damage either the upper or lower bearing on removal and require a replacement? may not matter if the intermediate gear and shaft is to be binned anyway.

Any info gratefully appreciated.

Even with ear plugs, the ear shattering shriek from this machine of when running at speed is tiresome, to put it mildly and puts me off using. While I have managed to avoid damaging the plastic gears so far, I suspect that is down to good luck rather than good management, so any simple mod that engineers out these two issues would be a delight!

Martin of Wick.