Well, now that school is out I can spend a little un disturbed time on this project.

I made some better progress today. After the previous mishap I marked a new centre hole on the same piece of blank steel but on the opposite side (this will be covered by the Angle Plate anyway).

After marking and drilling the centre hole, I placed the baseplate on the Compound Slide Swivel Plate (or Micrometer Pan), as it is called in the manual and transferred the position of the first hole using a 4mm drill. Once drilled and checked I transferred the position of the second hole in the same manner.

Here are the old and new sets of holes.

Next I needed to measure the heads of the allen bolts and counterbore the holes so that the bolt heads were not proud of the face. The problem was that, after turning the workshop upside down, the bolts were nowhere to be seen!!!

I then searched in all of my bags and the house, probably spent about an hour looking and after giving up, I found them later that day!!!

To counterbore, I needed an 8.5mm flat bottomed drill, which I do not posses, so I made one using a spare drill bit.

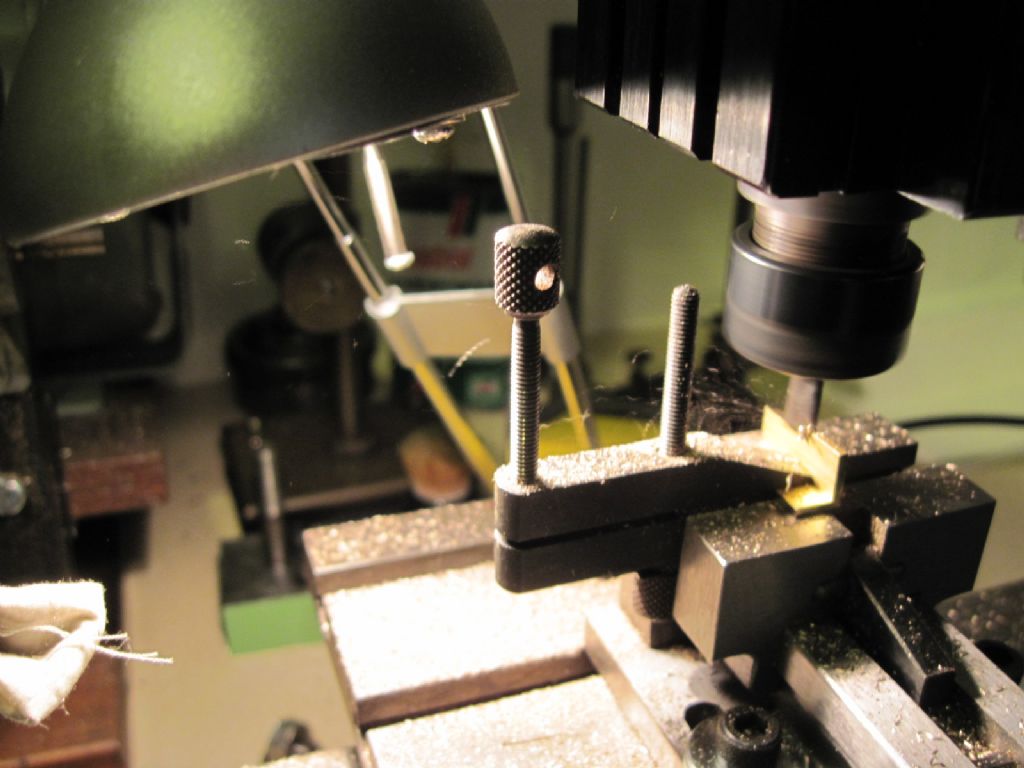

I started the hole with an 8.5mm standard drill bit and then lined up and went in with the flat bottom drill bit. For these larger drills I turned the drill speed down to 600rpm?

I also lined the drill up with the face of the material and set a depth stop.

Then lined up the drill bit, secured the work piece and in we went.

Here are the two holes, one is slightly deeper

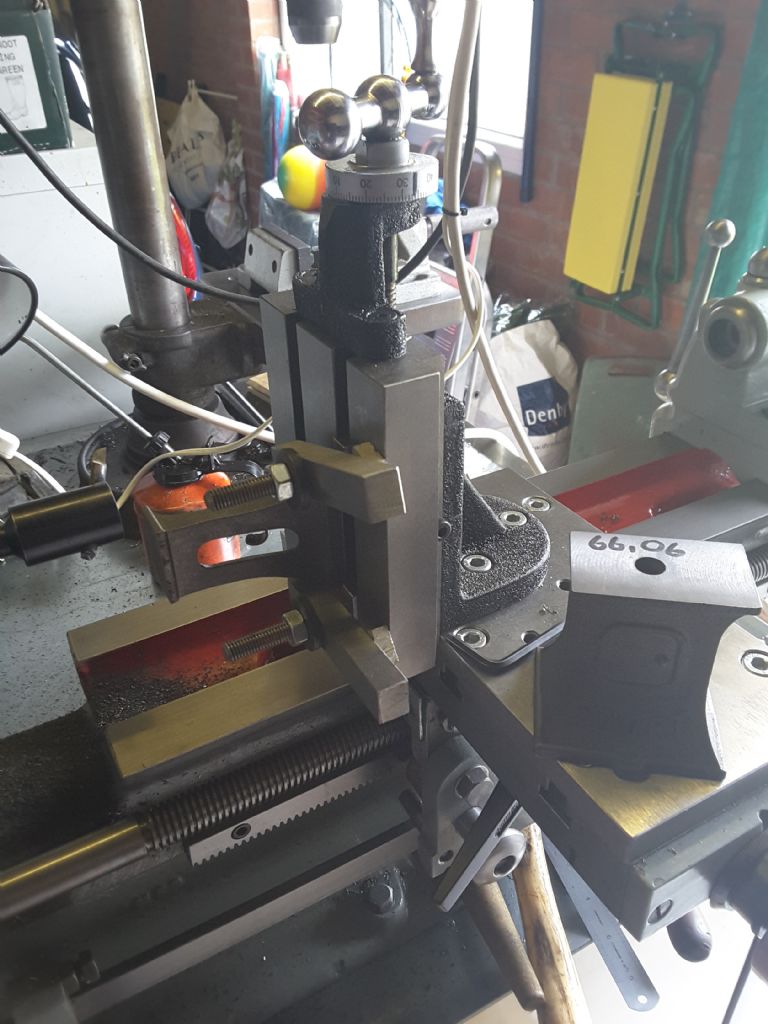

Here it is in place.

The bolts need shortening slightly and I need to make a recess in the base or maybe fit a shim, as the screw that holds the cross slide threaded nut in place sits proud of the face plate.

Jager.