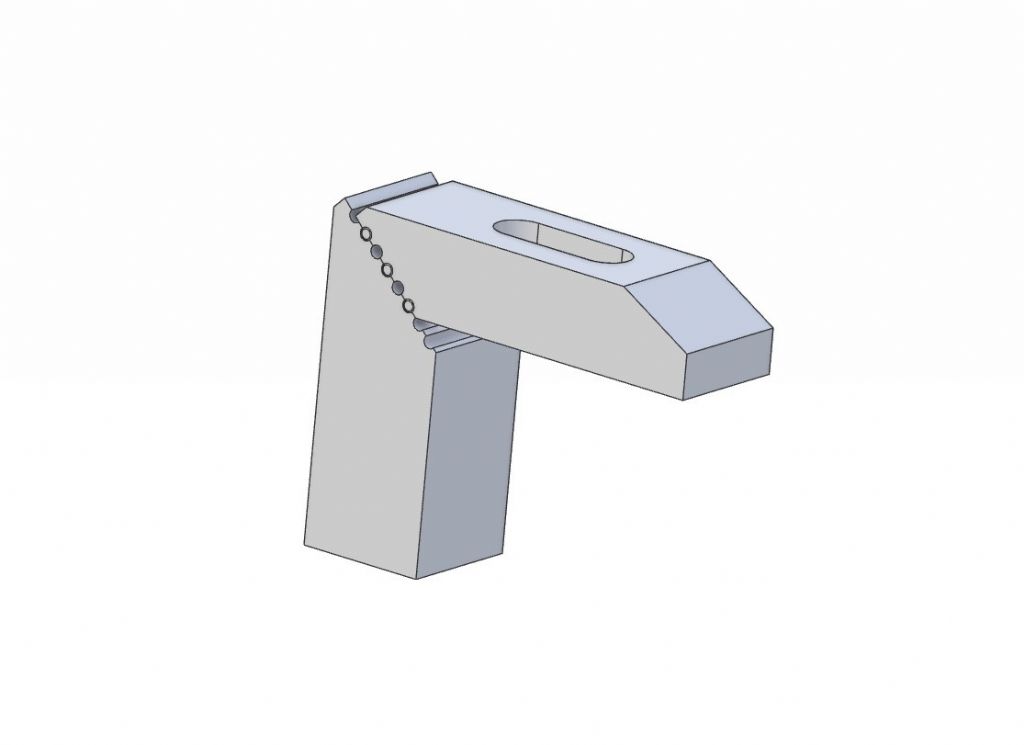

If you make your clamp bars with a tapped hole in one end – always assuming you don't consider making something for your self to use a waste of time – then the need for stepped clamping is more or less eradicated.

My collection of 6mm capheads range from 8mm long to about 120mm – anything longer I use studding. A reversed caphead in the clamp gives a good clamping supporting surface and is infinitely adjustable

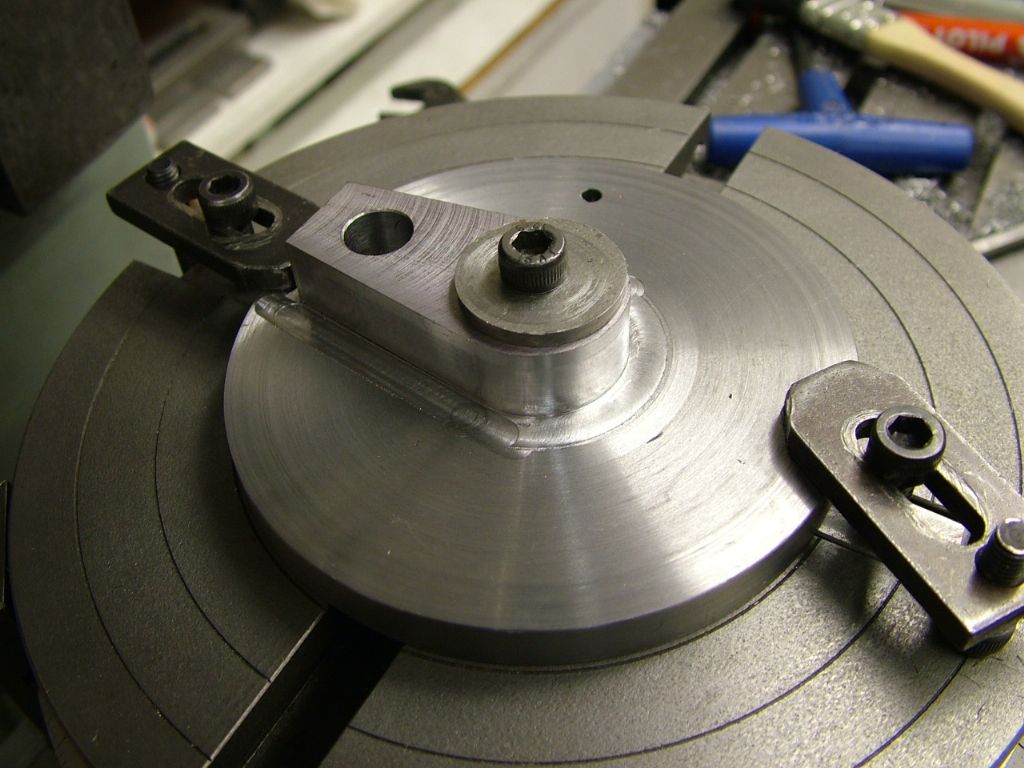

I have a set of those Picador blocks that are shown above – I don't think they've seen the light of day for forty odd years – indeed the way they easily keep falling apart as you're trying to set them up and difficulties of holding them in place on a faceplate led me to the system I now use. If you have a stack of them a caphead dropped through them but short of the table keeps them in line.

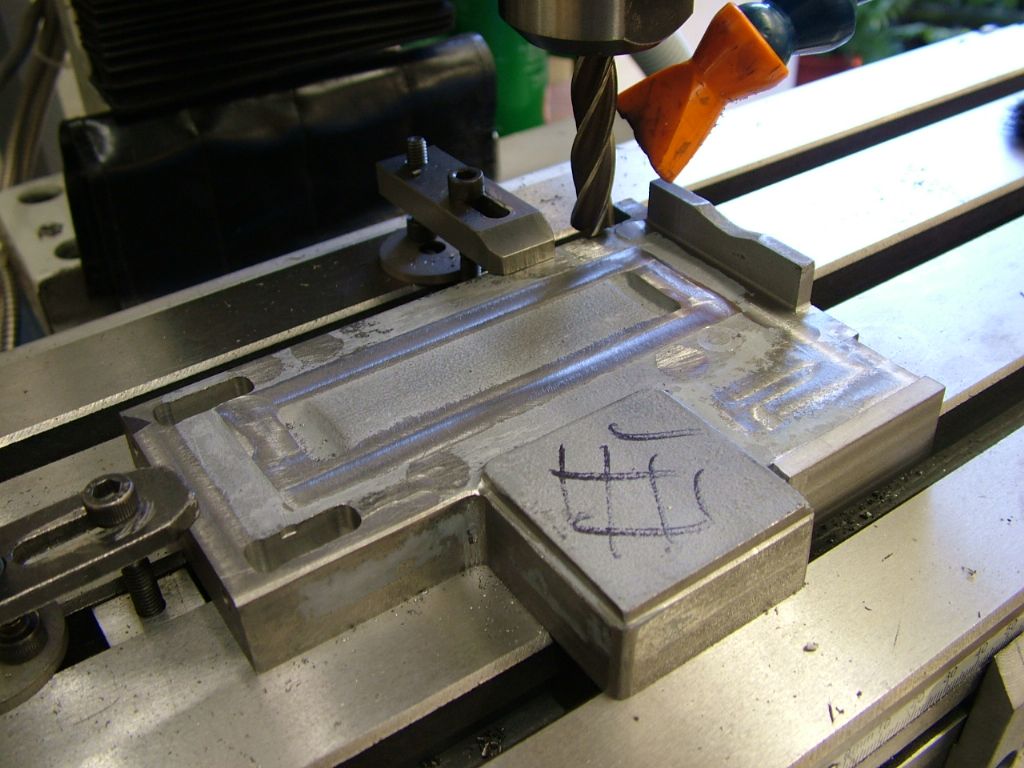

It's always desirable to buy 'kit' – not least a clamp kit to mount beside the mill. Depending on what you are going to make of course but something based on the above is far more practical for the milling machine in question than spending on something that for the greater part will sit idle.

As always, it's down to choice – horses etc., but I think I'd rather spend a few hours using my new mill for making something that I will use forever on it and spend the money on something I can't – a decent set of parallels for instance.

What ever way you go Bosun enjoy your machining

Tug

Tug

Edited By Ramon Wilson on 19/11/2021 22:40:09

David George 1.

David George 1.