With issue 289 about to be available in digital here are a few additional photos to go with part 14.

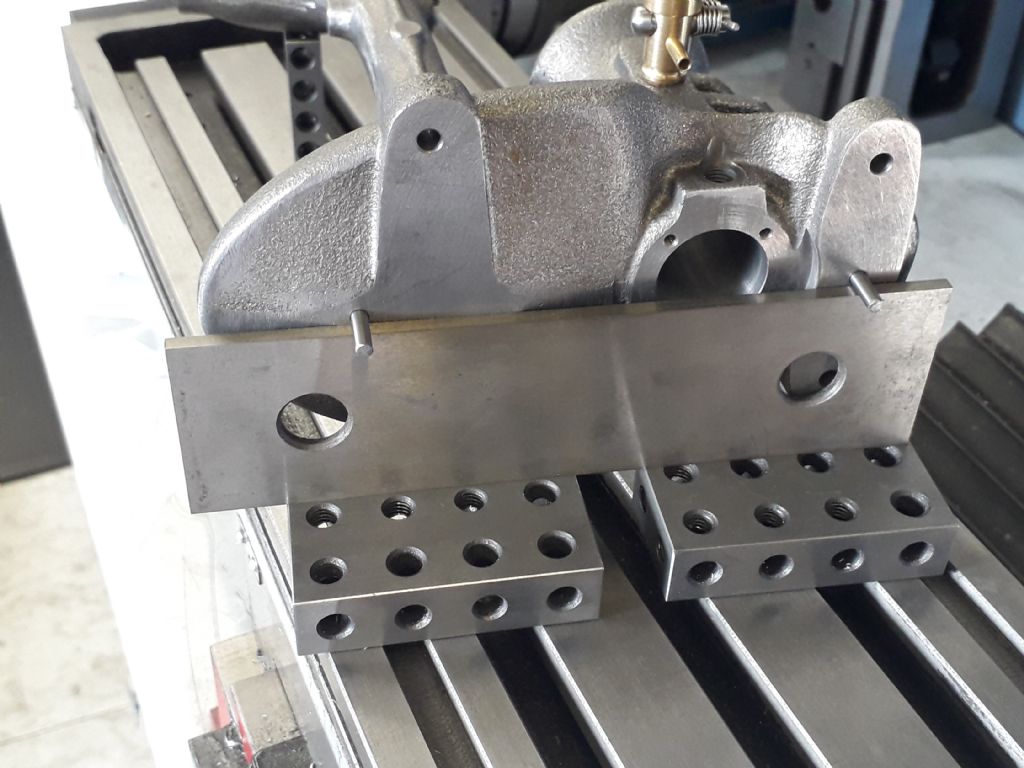

A posed photo to better show how the two pins inserted into the base of the casting along it's front to back axis can be used to set the casting for machining features at right angles to that axis.

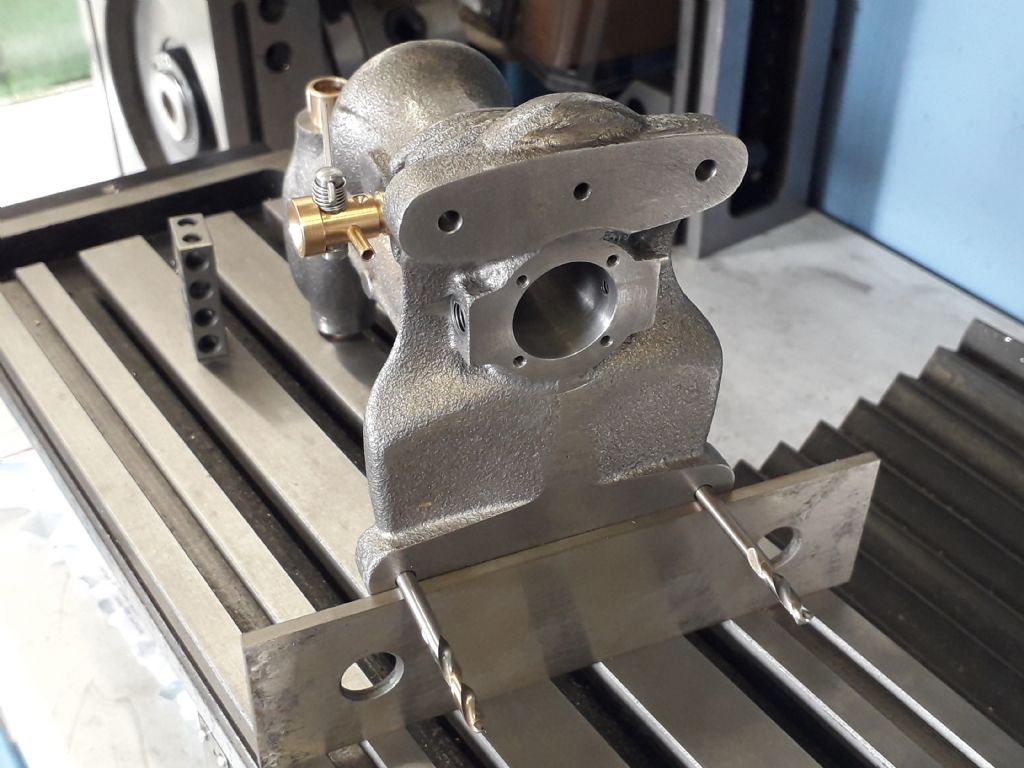

A similar setup but making use of the castings mounting holes to take pins (drill bits) to rest on the parallels

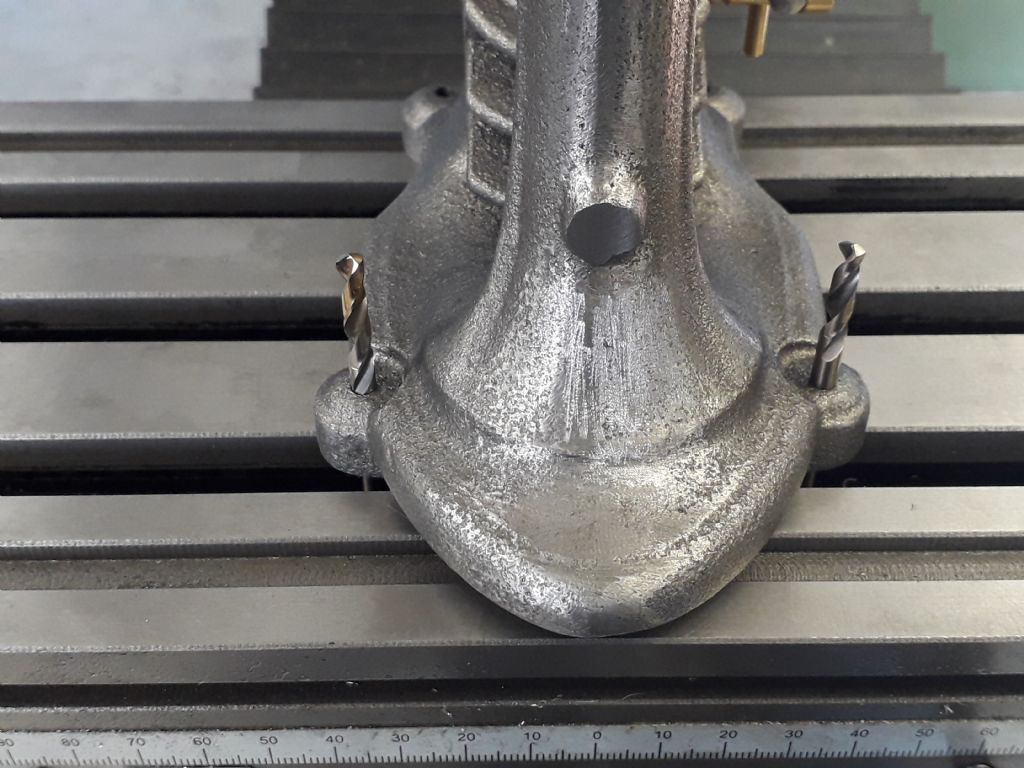

Using the same mounting holes to line up the casting but this time with the pins (drill bits) set against the side of the mill table's tee slots.

Close up of the pins against the side of the tee slot

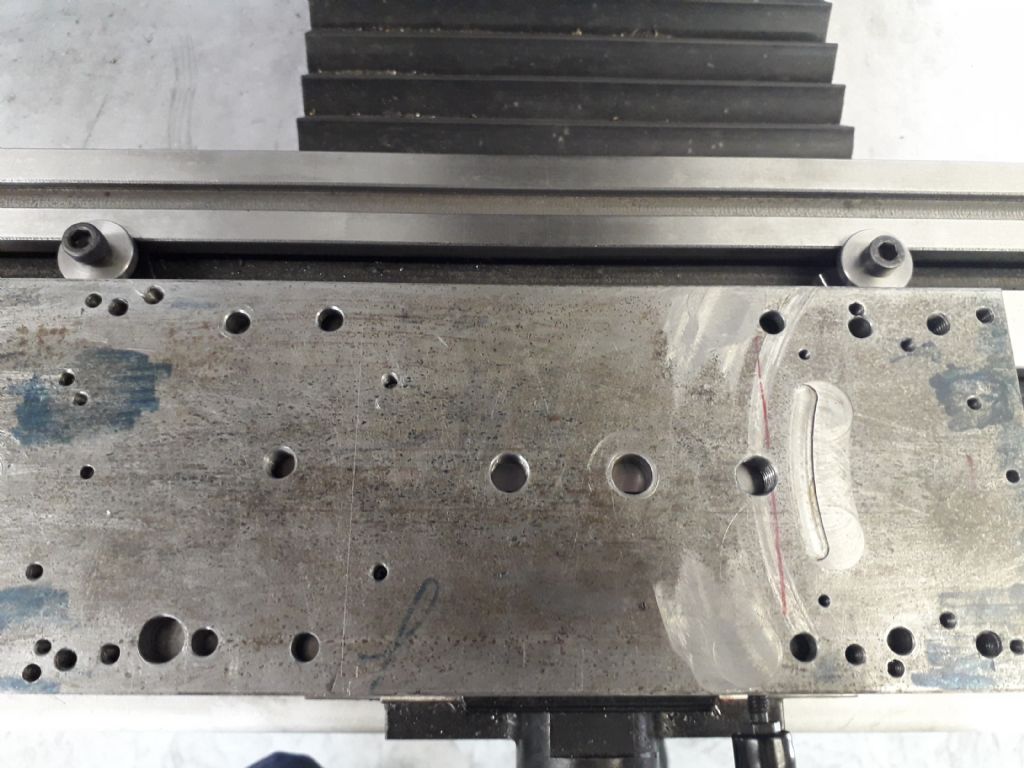

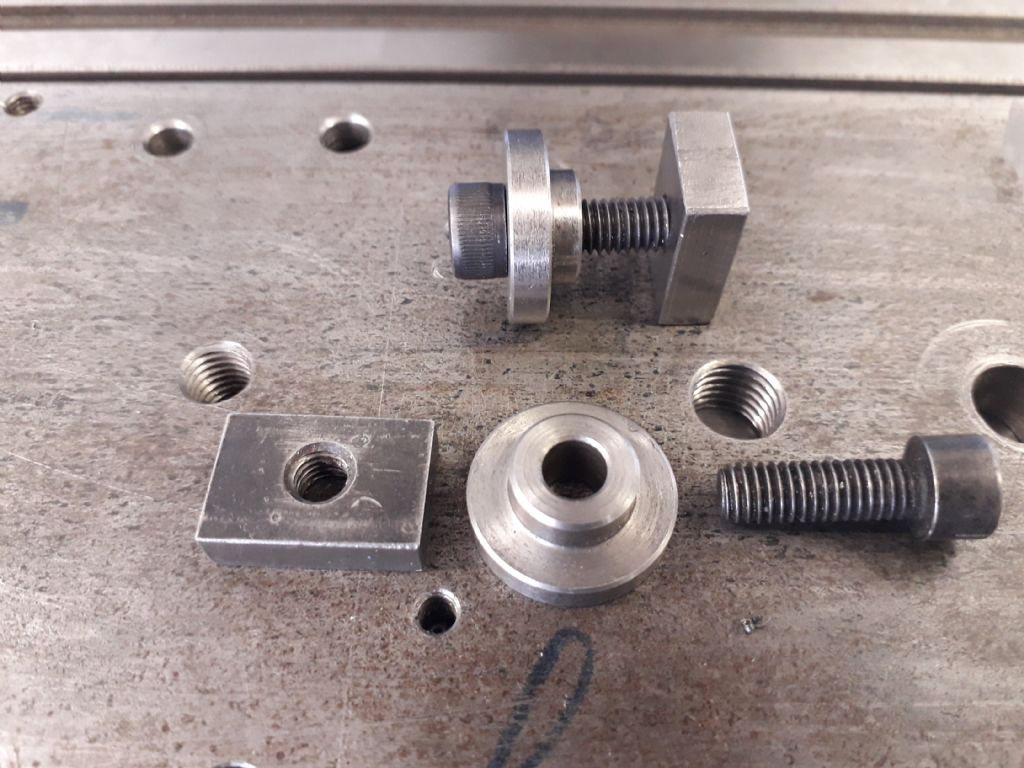

If using a machining plate that will need to be repositioned several times then some simple buttons can be made to fit the mill's tee slots and then the edge of the plate placed against them. Buy using two slots and adjusting the position of the buttons the plate can be quickly reset at an angle which would be time consuming to have to set up each time the plate is moved

Close up of the buttons for anyone wanting to make a pair.

Journeyman.