Well the postie finally came and dropped off a box with some goodies inside.

Yesterday I had opened that M10 hole out to 10.3mm ( actually 13/32" ) and tried my taper tap in it which has no make on it and don't recall where or when it arrived in the workshop as it is not a size I use that much. I tried two chucks both keyed and keyless but it just stuck and span in the chuck, changing to an ER32 wich just tripped the machine instead when it got too much.

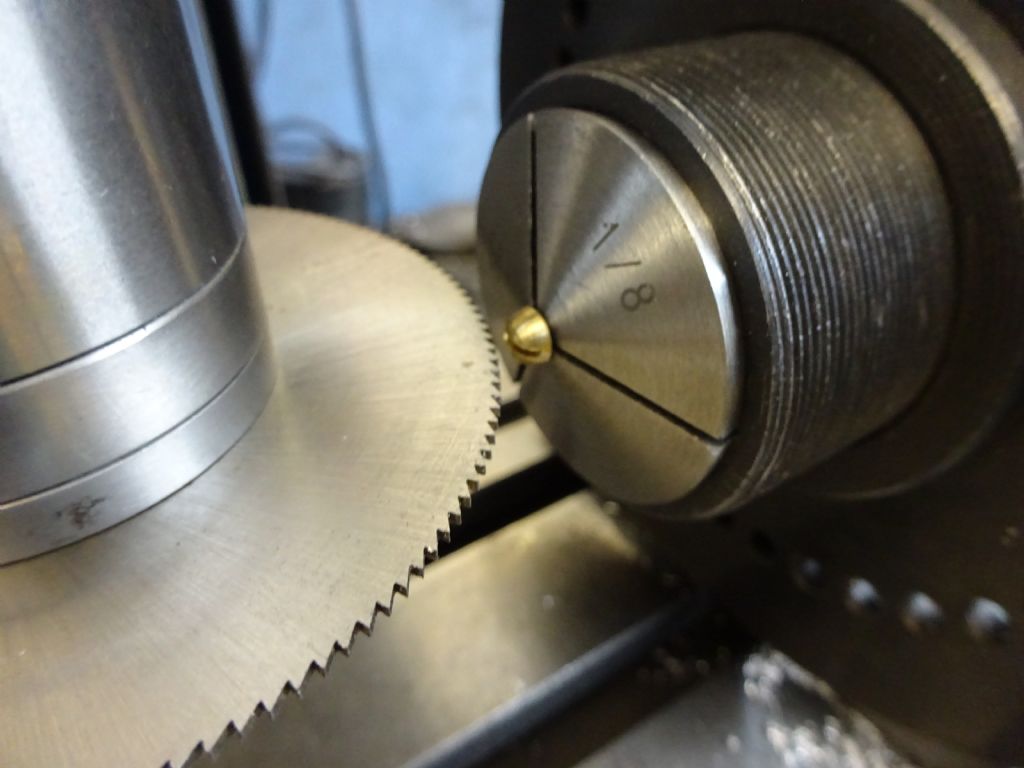

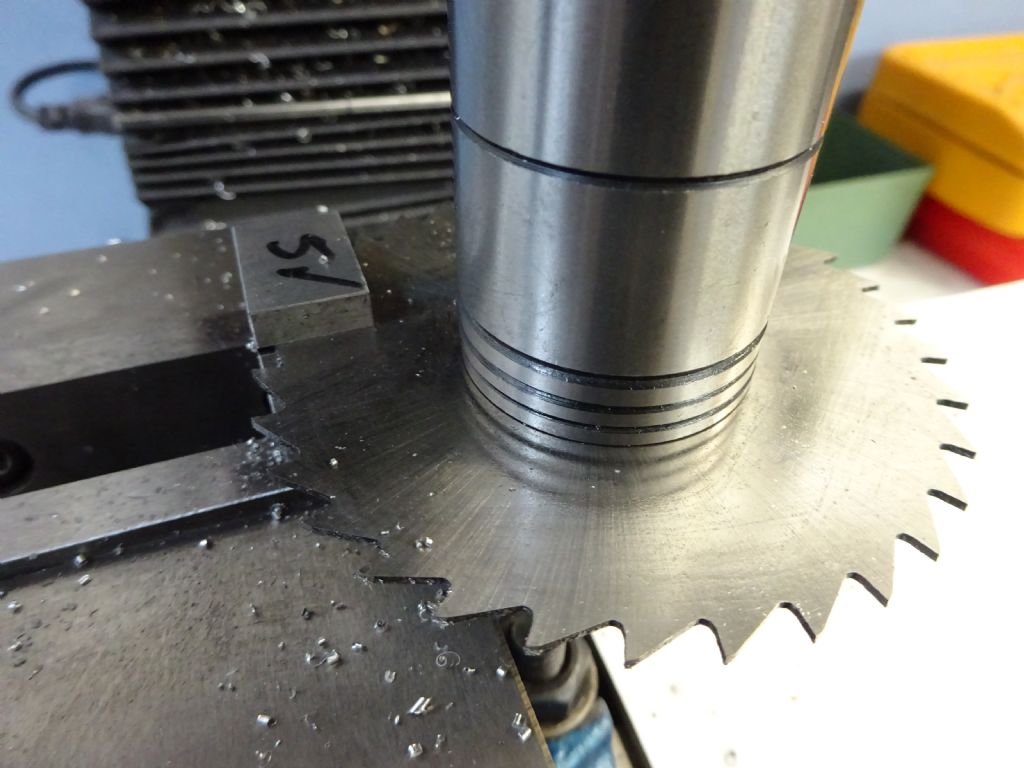

So armed with the set of spiral flute taps from ARC Euro Trade's new range and suitable tapping drills I popped a 10.2mm hole into another offcut of 1/4" steel, reverted back to the keyed chuck that came with the SX2.7 to hold the M12 tap, set machine running at 150rpm and had a go. Slowed a bit at first but then just powered through the hole with a clean looking thread produced.

I would say that is about on the limit for what this machine could do and would not want to do a lot of them in quick succession, 10.2mm does give a high percentage thread depth and that could always be upped a bit to make life easier on the mill but may try at a few other speeds which could prevent that initial slowing. Will test them further and hopefully have something to go in the next but one MEW.

J

PS Nice boxes too.

Edited By JasonB on 27/06/2019 17:56:48

Journeyman.