I got out to the shed last night for some more measurements, but unfortunately (?) I was mugged by a bottle of wine on the way back in and failed to report!

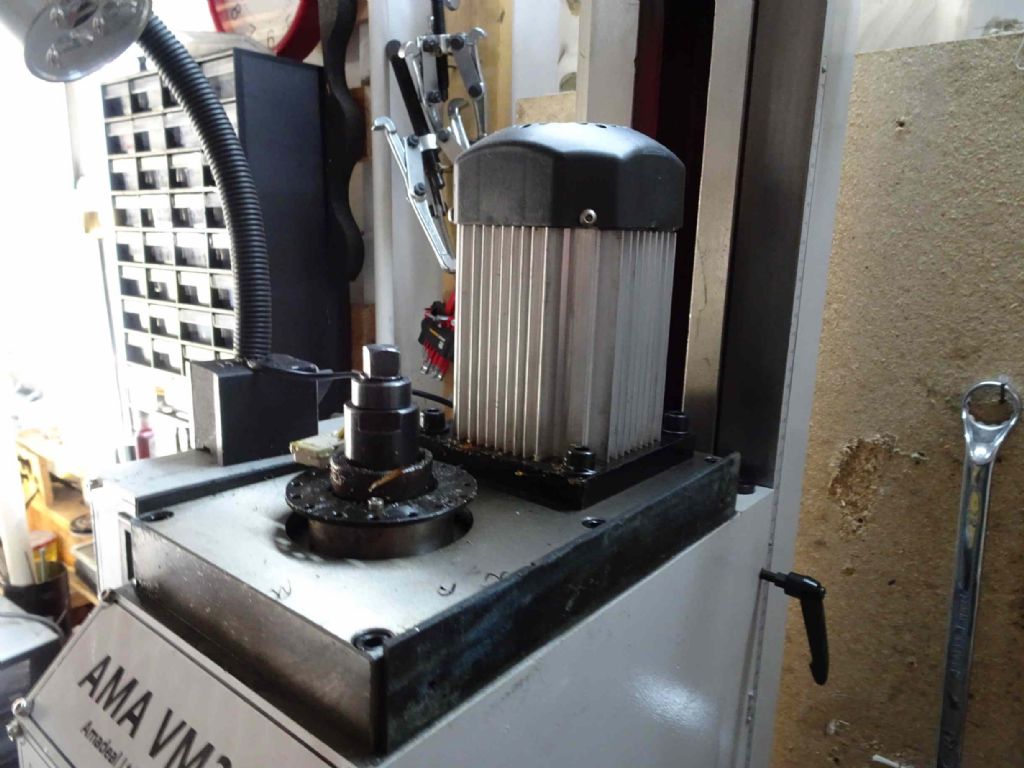

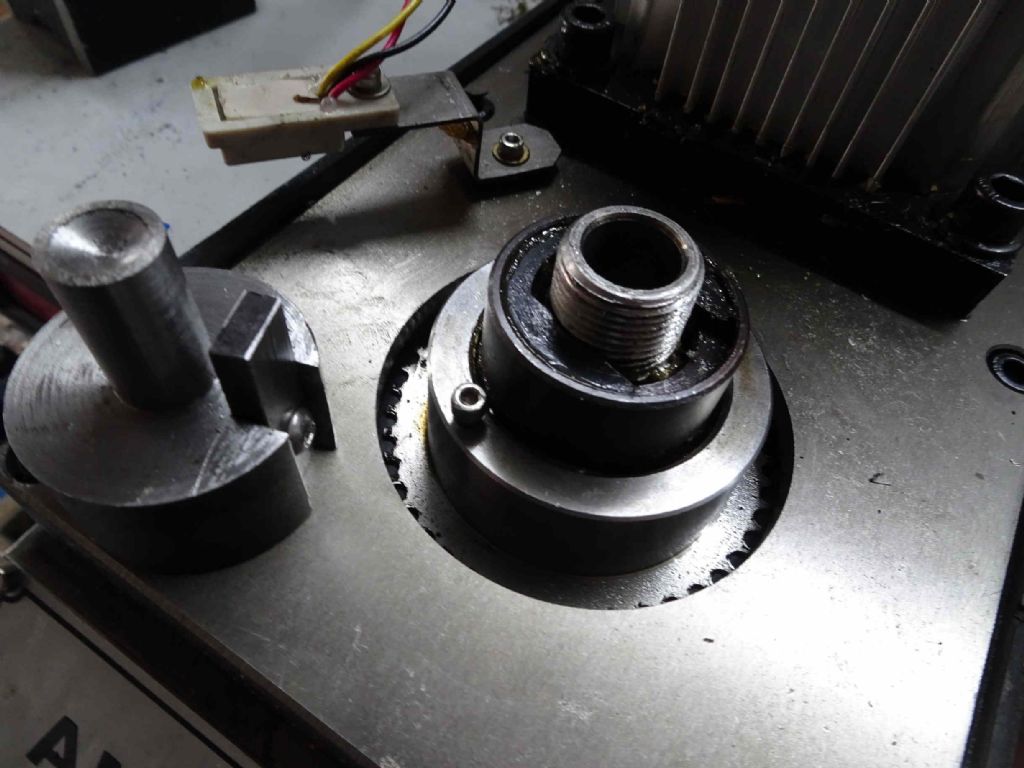

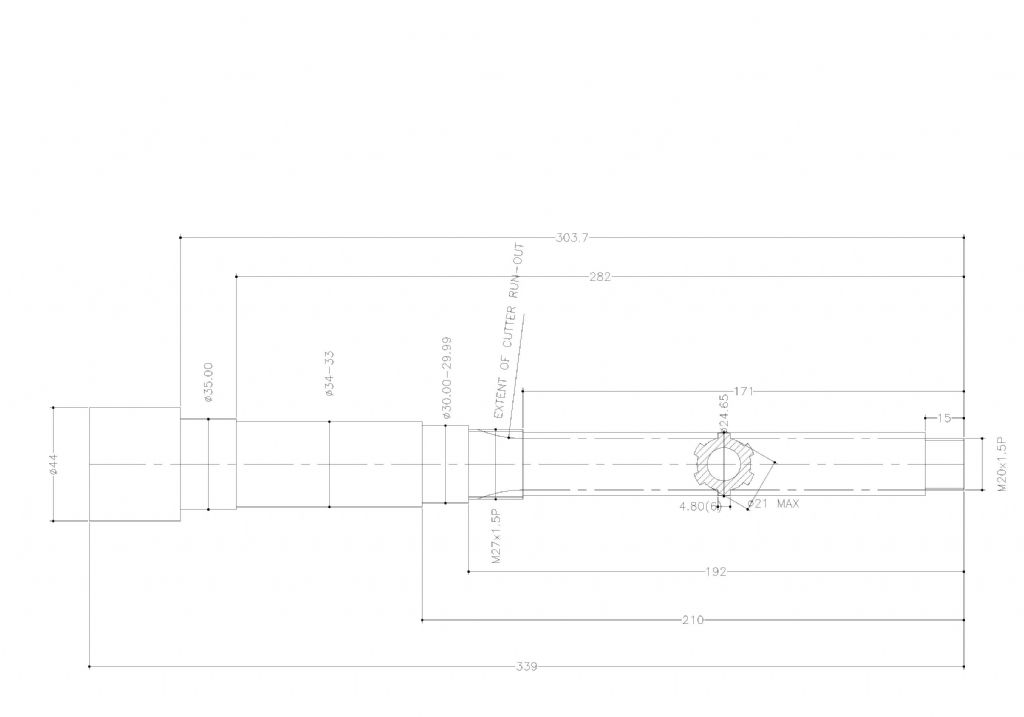

I looked at the runout on the 50mm face mill. On the body of the mill I saw 30 microns, On the arbor I saw 10 microns and on the spindle 6 microns.

A less capable indicator inside the spindle showed about 3 or 4 microns – barely a twitch on a 0.01mm indicator.

I also put a spot on the point on the rotation of all (body, arbor, inside spindle and outside spindle) of a minimum and they were reasonably in line.

I tried again with the 20mm bar. This time (for variety) with the 3rd of the 20mm collets I own. Before I installed this, though I backed the set screw out half a turn or so and the drawbar screwed up nicely. At 100mm down from the spindle I had a run out of about 46 microns or less than 2 thou, which is unlikely to make me lose sleep.

But this didn't marry up with the results of the machining test, so I decided to pull the quill all the way down and test again. With this mill, if you want to reach near the bed, you have to pull the quill pretty much all the way out, so that's how the machining in the previous post was done.

The result shocked me.

The first (and not particularly shocking result) was that the runout went up to 60 microns.

Then I noticed that if I pulled the bar to the left, it moved quite a bit and slowly (1 second) settled back to a lower value (about 20 microns, perhaps). If I pulled the bar to the right, it moved quite a bit and settled back to a higher value. That it moved slowly was alarming, but that there was 33 microns between each of the two 'settled' points was 33 microns or thereabouts. This was repeatable.

When I was turning the spindle to check the runout with the quill extended, I noticed that it was really quite rough, so I thought I'd try it under power.

Here are some videos – forgive me if they aren't quite as slickly embedded as others manage.

First the spindle rotating about as fast as I thought the indicator could cope with: here

Then running about as slow as it will go : here

And finally returning the quill to the top and running at a reasonable speed : here

You will see that the rotation with quill up is reasonably smooth, but with the quill down it's a mess.

I've left a message on the Amadeal ansafone, but heard nothing back yet. I'm not even sure if they are open. I will keep trying.

If this sounds like anything you've come across or have any ideas for more investigation, I'd appreciate it!

Iain

Graham Meek.