How much space do you have? And what do you want to do with it?

General rule with machine tools is bigger is better unless specialising in small work. It's because big machines can usually do small work, albeit uncomfortably, but small ones can't do big.

Anyway, assuming you're after a mill that will sit on a bench, there are various options.

One of the many attractions of clockmaking is that the equipment doesn't take much space, and is clean and quiet enough to be done indoors: box-room, or under the stairs etc, Same applies to small-stuff hobbies like jewellery, model-railways, and makers adding modest metalwork to 3D printed items. The Sherline Mill is popular for this scale of work:

Or, bit bigger, a Far Eastern micro-mill, this example is sold by ArcEuro, an SX1LP, weight 50kg:

The micro-mill is first in a series of similar machines, each bigger and more capable. From Warco, the WM12 (weight 54kg), WM14(60kg), WM16(113kg), and WM18 (220kg) Of these, I think the biggest I would put on a bench is the WM14. A WM18 is much too big.

Although the WM12 and SX1LP are similar, there are reasons for preferring one over the other. For instance, the SX does high RPM with a less powerful motor. This may be exactly what's wanted on a small milling machine. Small cutters work best at high-rpm, so with a 2mm diameter drill in the chuck, an SX should do better than a WM12. However, if the mill routinely tackles larger work (still small), I'd expect the WM12 to win, because it's more powerful motor can also manage the lower rpm needed. With a 6mm drill in the chuck, the WM12 has the advantage. Both machines will do the job, but they're not identical.

Proxxon sell a micromill too:

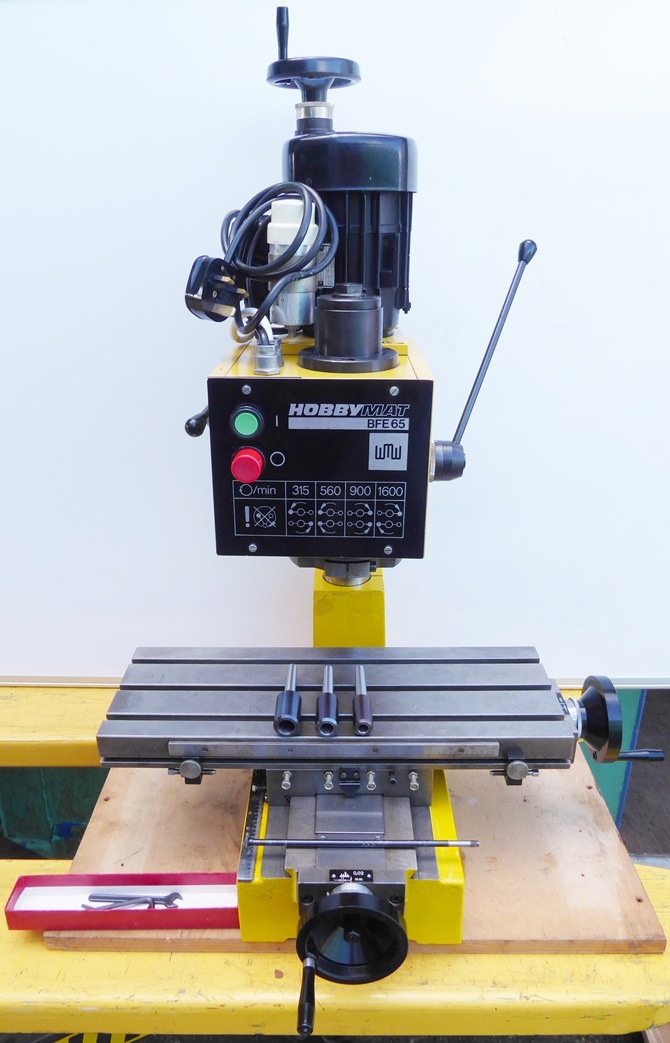

There are second-hand possibilities too, but with these condition is everything. This example is a Hobbymat:

Ought to say affordable small milling machines get mixed reviews. I suspect the problem is they have to be operated carefully within their limitations. They're not powerful or rigid, so anything remotely heavy handed will cause trouble ranging from low accuracy, to cooked electronics and burnt out motors via stripped gears! Patient delicate cutting rather than showers of red-hot swarf!

Can you say more about what the mill is for? Clocks and motor-bikes are very different.

Dave

Dave Halford.

Dave Halford.