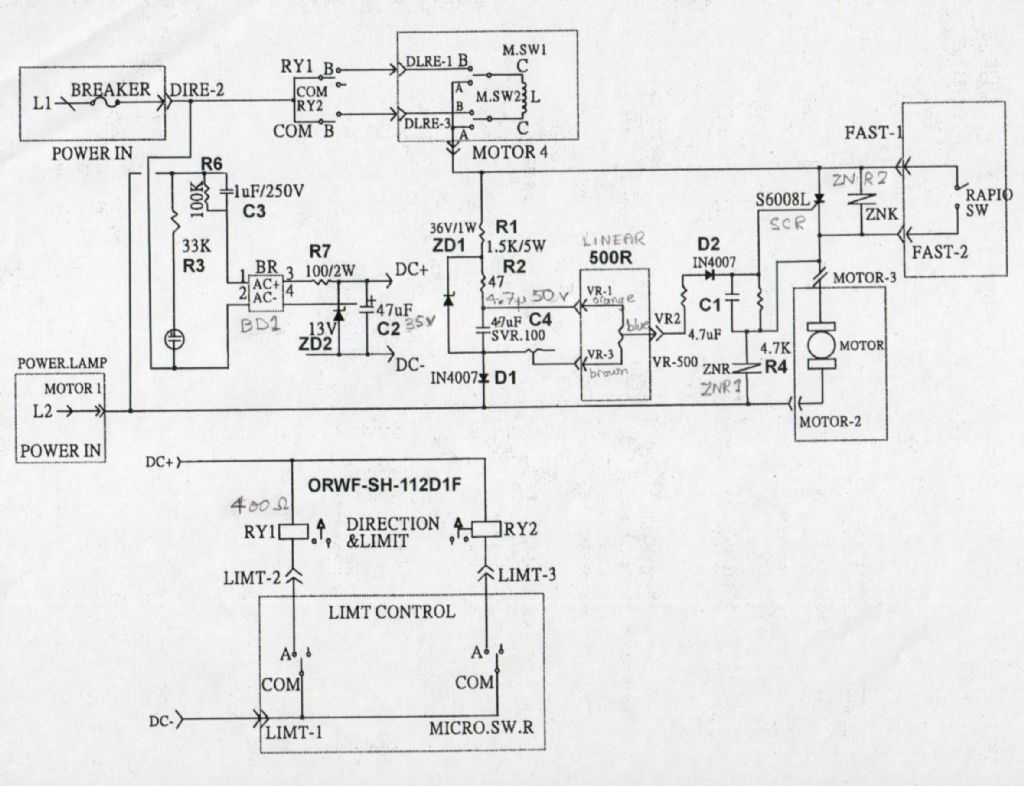

Here is a circuit diagram of an Align power feed. There are several incorrect diagrams on the web, but this one seems to be correct for my unit (though it is a different model).

It is certainly worthwhile checking thoroughly for any defects. Near minimum speed, any mechanical unevenness will easily cause speed fluctuations. The best of luck working inside the unit, it is not well designed for component access, though the circuit board isn’t too bad.

According to my ancient GE SCR Manual, circuits like this mostly use motor back EMF to help with speed stability. Unfortunately this must rely on residual magnetism to work, the field not being energised at the point of triggering the SCR (thyristor). In some cases the motor field yoke is made from a material with high magnetic remnance. Anyway, as already said, my unit works surprisingly well, with the available speed range pretty well matched to needs.

To use the motor with a different control method would probably need the field to have its own power supply (parallel field), otherwise you would be stuck with a series universal motor configuration. The voltage for the separate field supply might be able to be increased relatively, resulting in slower motor speeds. Also note that the armature will probably need only 50V DC for full speed, and only a few volts for the wanted speed range.

UncouthJ.