Hello Morgens there are two books which whilst they were written at the middle of the last centenary are still well worth looking at. The books are both by F.W. Britten. The most useful is ‘Watch and Clockmakers’ Handbook (Dictionary and Guide). This is a sort of encyclopaedia. The other is ‘Horological Hints and Helps’. I think I bought my copies (which are reprints) from Camden Miniature Steam Services (usual disclaimer). They advertise in the Model Engineer.

What you want to do by shortening your clock will mean a complete redesign of the whole clock. There are very close relationships between the length of the pendulum, the count (number of teeth) of the ‘scape wheel, the span of the escapement and the ratios in the ‘going train’ (the rest of the cogs). It is the pendulum length which is the foundation of the whole clock. To put it more simply a clock is a device which counts oscillations. Change one part and you will have to change all.

If I may give you one more Krona’s worth of advice do not work to normal engineering ‘fits’ they will be far too tights. Clocks are built with a rattling good fit. I learned this the hard way. It took me many days to figure it out. Keep everything LIGHT! (as light as you can).

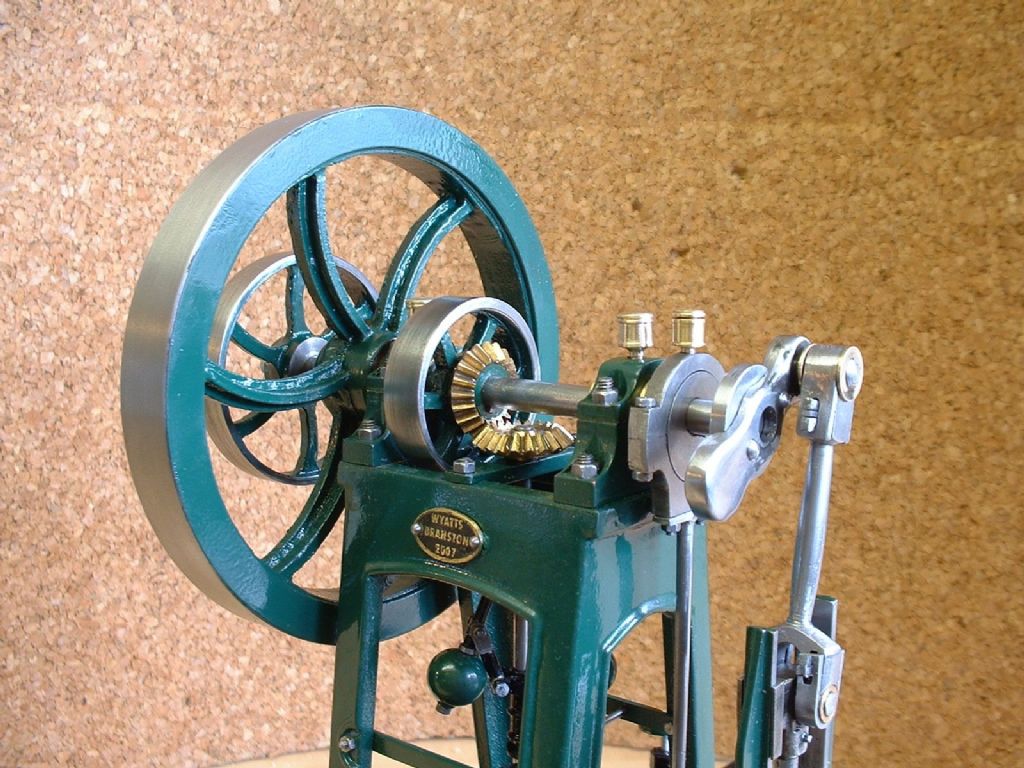

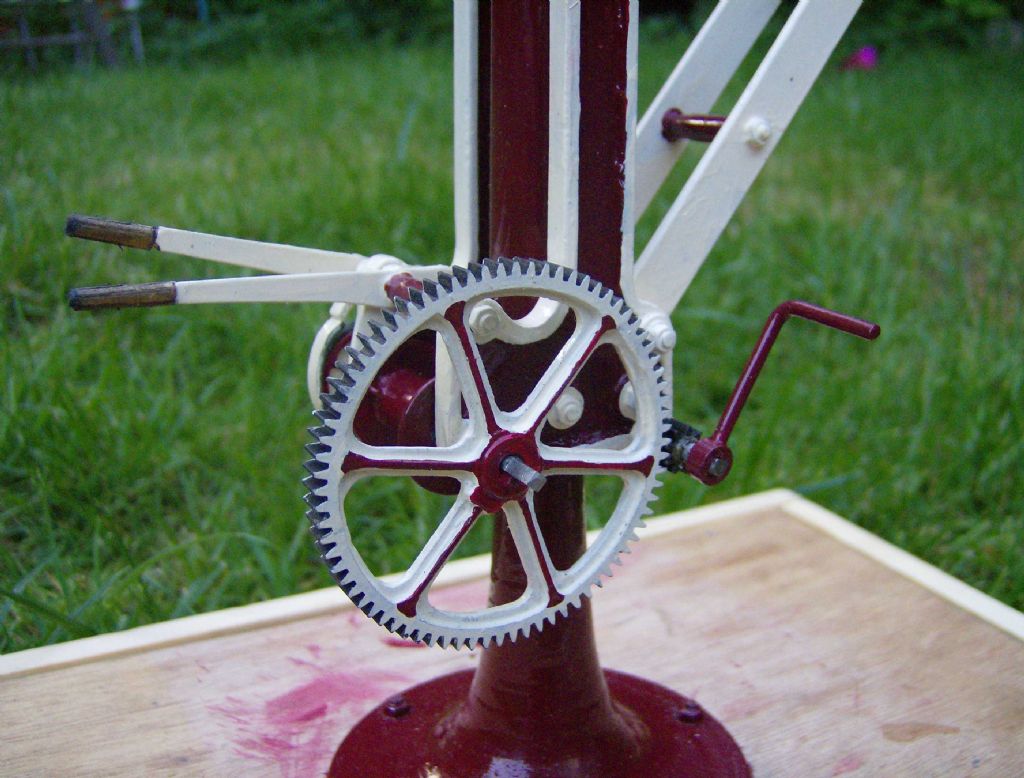

NJH – thanks for the ‘plug’. I have used the method I describe in Model Engineer and with care, it works well. I have used it to make the wheels for three clocks so far. It can be used to make straight spokes for flywheels and other similar things. I now know how to use it to make tapered spokes, but there are complications. Until I have used it and know it works I will not write it up. If anyone has problems with the method, send me a message via this site. I must also thank the Editor of Model Engineer for the drawings (mine were dreadful).

I will not comment on steel/cast iron wheels, I have never used them.

Edited By Richard Parsons on 13/12/2010 06:35:36

Richard Parsons.