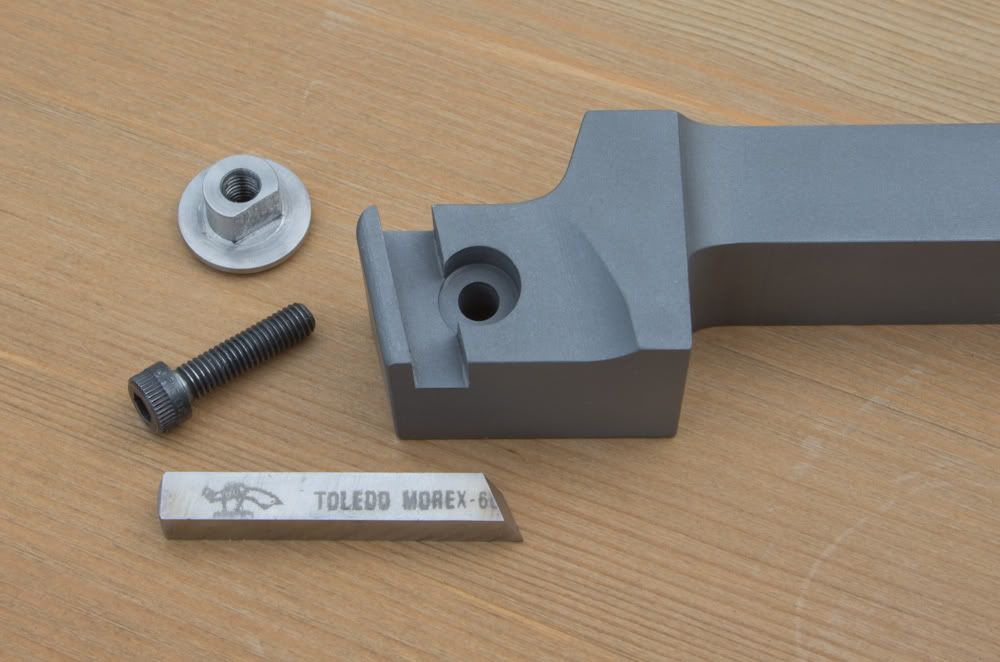

Lacking a chunk of metal big enough to make Michael Cox’s toolholder without wasting loads, I’ve just milled a crude copy of the eccentric holder out of some 3/4″ bar.

It’s a bit rough as it was very much an experiment to work out how the clamping manages not to foul the work. The answer is ‘with difficulty’, I had to grind a lot of the clamp away. I ground the top of the tool by eye, and tidied it up and out a tiny radius on with a diamond slip.

Problem was I made the clamp ‘hooked’ around the front edge of the bar; the eccentric tool squeezes it from the sides. but at least I’ve worked out how to get the angles.

I was still able to see what happened on some intractable 1/2″ stainless. And the result – was rather good. At least as good as any other tool I’ve used on what is nasty work-hardening stainless. The swarf came off as a continuous spiral, hot but not blued. Depth of cut was about 20 thou with 4 thou fine feed.

Another try needed to make a tool that will face and deal with large diameters, but on the wholea useful proof of concept.

Neil

Grizzly bear.