Posted by Ray Lyons on 20/02/2022 15:54:04:

Some time ago, I said that when number 300 was reached I would stop the subscription since my time in the workshop is now limited and the contents of many of the articles being computer based were of little interest to me. Here we are, No 313 and I still manage to find at least one little gem in each edition.

This time it is John Purdy's quick stop for quill machines. It was just after Christmas when I was last in the workshop and trying to make a stop system but John's idea is much better and I will have a go when the weather allows.

Then there is the photos of his indexing setup on the Myford lathe which requires little explanation. One job on my list is to engrave dials for my almost finished T&C grinder and that shown seems to be a simple method.

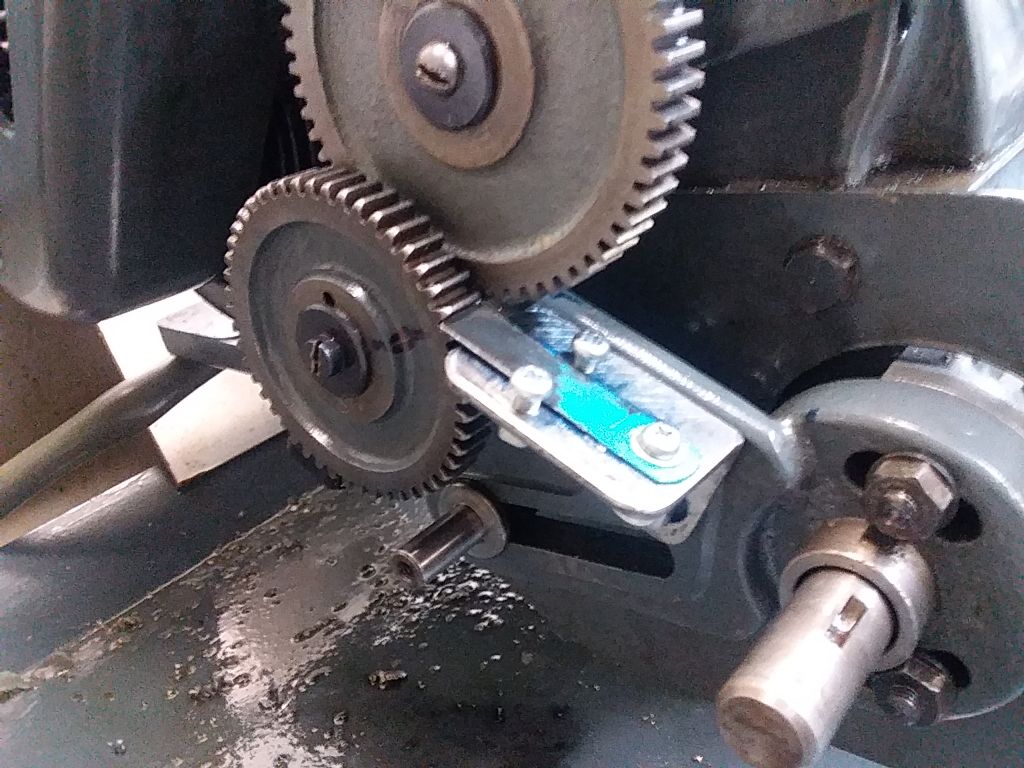

Ray, I haven't seen issue 313 yet but here is a pic of a simple method I used recently to graduate some cross slide dials. Made from a bit of hacksaw blade and a scrap of 1" steel angle bolted to the banjo, engaging with a 50T gear that is geared 2:1 with the spindle.

I found it way quicker than using my previous spring-loaded detente plunger because you don't have to look away from the dial in progress to move to the next position. Just rotate the chuck and the hacksaw blade clicks into the next tooth slot. I set it so it would allow movement in one direction only. And used a piece of cord wrapped around the chuck and up over a pulley with a weight on it to keep the gear tooth firmly against end of the hacksaw blade "detente".

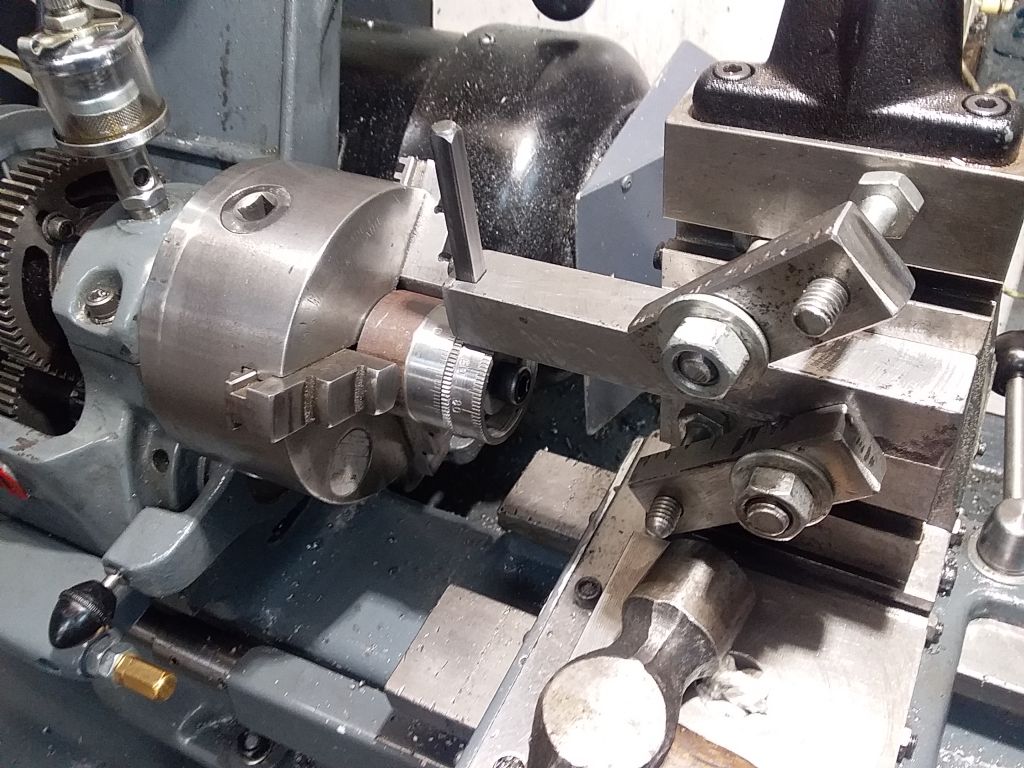

And here is my quick and dirty tool for stamping the numbers on nice and straight and even. A piece of square bar held on the vertical slide. Bar has a 6mm slot milled in the end to hold the stamp. Slot is closed off with a piece of thin plate held over the end by two small screws. Worked a treat. I used the hacksaw blade detente for the stamping too. Each number was one click before the mark, and the accompanying 0 was one click after the mark. Made the job really quick and easy. EXCEPT, not all cheap Chinese number stamps have the numbers in the set all perfectly the same alignment relative to the square shank, so there was still some small variation which was annoying but probably nobody would ever notice.

YOu can see too at bottom left the carriage stop used for "planing the graduations on the dial to uniform length. I did the short marks first, skipping every 5th mark. Then advanced the topslide to make the "5" marks 30 thou longer and went around and filled in those ten marks, then the same procedure again with with longest "10" marks. Much easier (for me) than trying to do the longer marks as you go and then going back to the shorter and so on. Just cranked the carriage back and forth by the handwheel. It all worked rather well.

(I don't know what my favorite tool is doing lying on the cross slide in that pic. I was not even working on Harleys that day.)

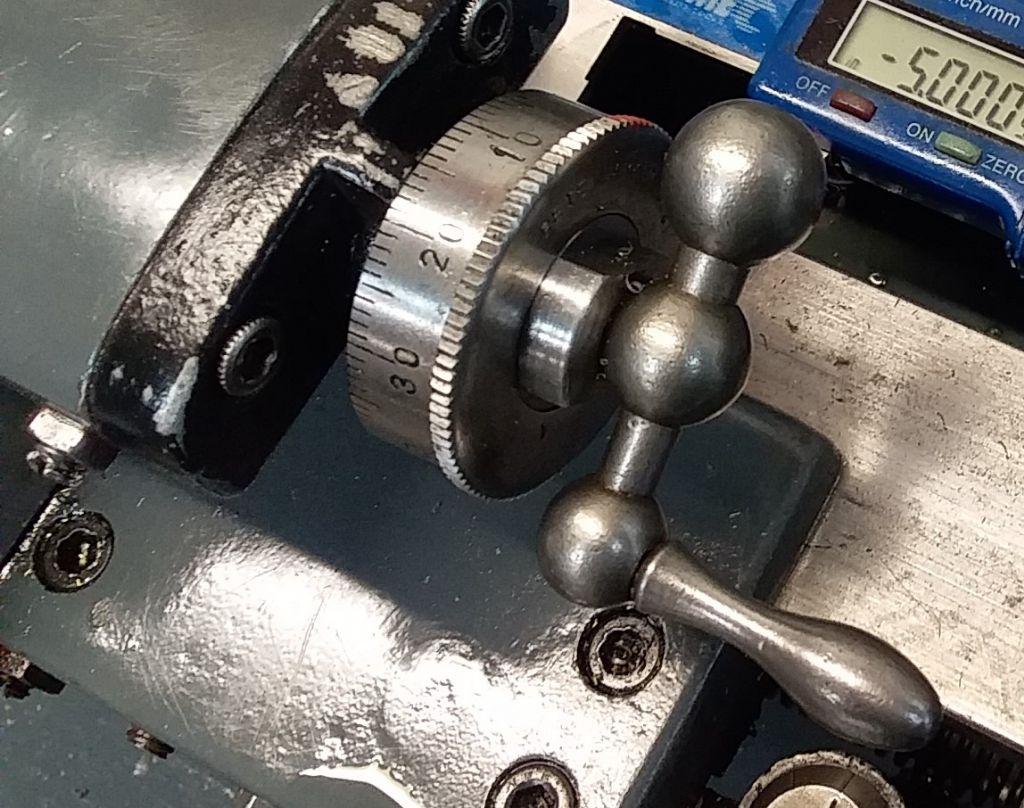

End result I thought was passable. You can see though, the 0 on the number 30 is clearly leaned to the left at the top of the number. And on the 20 if you can see through the glare. And the 0 is slightly shorter than the other numbers But that's the way the number stamp was made. Annoying after all that work!

Edited By Hopper on 21/02/2022 12:08:39

Neil Wyatt.

Neil Wyatt.