What seems to have been missed is that BA screws are available with size-smaller heads, but what in fact are we trying to replicate? The original Whitworth hexagons, which would be right for many models, were larger than those later used so if wanting very close matches to scale surely we should compare the early proportions to what is available now.

Where the original size is uncertain, as when constructing a model to manufacturer’s drawings or other archive material, or when trying to metricate a long-established published model plan-set, one approach is to multiply the candidate fastener by the scale to assess its proportions.

This is a case where finding very old, and preferably even contemporary, engineering trade reference-books can be valuable by giving typical detail proportions of components and their fastenings; often quoted from manufacturers’ drawings.

Very early machinery often had square nuts on square-headed bolts anyway, and here we have no choice but to make the fastenings if we want correct replication.

.

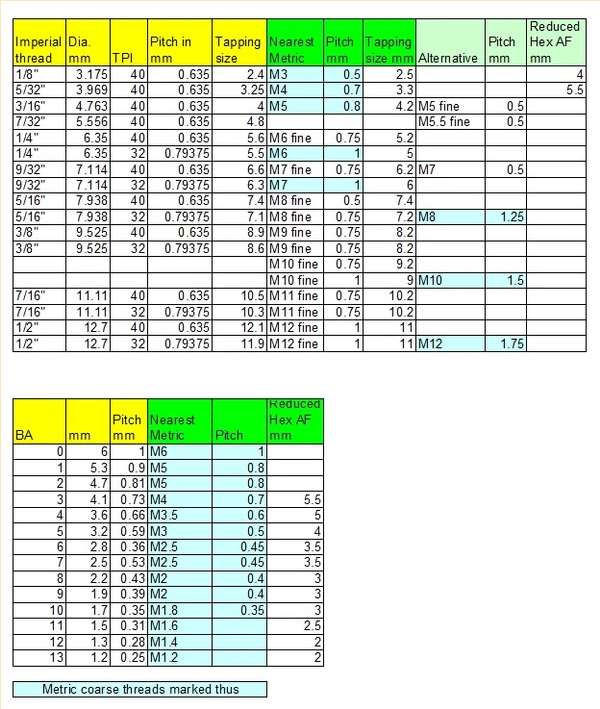

Also, ironically, BA is of course metric, based on the Swiss ‘Thury’ system – although BSI describes it in inches – and its full range is by geometrical progression broken by the odd sizes becoming “non-preferred”. It does though have very few close matches with ISO fasteners, by size, and different thread-form.

To my mind the aesthetic objection to metric fasteners is less the size (the larger the scale the less noticeable the effects anyway) than the roughly-stamped bolt-heads, with embossed numbers. I suppose if you are really worried about this you could skim the heads smooth.

It is difficult to see why BA might be thought “superior” to ISO-M screws except where scale size and appearance really are critical, and BA is the nearer. There may be some advantages in some situations, by the BA’s finer pitches.

The point about BSW and BSF of course is not some sense of “superiority” but of fidelity. If the prototype used Whitworth bolts, then in the larger scales at least, Whitworth fastenings are correct. Not only historically, because the outward appearance is not affected all that much and the function is not affected at all. Rather, the hexagons are proportional to diameter. E.g. a modern 1/4″ BSW nut and bolt will be correct for a 3/4″ or 1″ original at 3″ or 4″ scales if that used the later standards. If the prototype used the early Whitworth proportions the modern fastener will be very slightly small but still proportional to its diameter at any scale. The difficulty comes in the very limited ranges of BSW / F fasteners now made, meaning if you really want the Gold Medal having to make the things yourself.

.

When I embarked far too long ago on my steam-wagon project I started with UNF! Why? Readily-obtainable fasteners (and spanners) when BS was beginning to disappear, inch dimensions compatible with the rest of the vehicle, usefully fine pitches, consistent diameter steps (by 1/16″ from 1/4″ upwards), and very neatly-finished hexagons both proportional to diameter and usefully but not noticeably smaller than the BS equivalents. With BA sizes for 3/16″ / 2BA and below. This though was in six-inch, subsequently four-inch, scale.

.

If the ISO-M series has any real consistency in diameters and proportions I have yet to find it. The range seems to be broken into rather random sub-series interrupted by random alternative pitches. M5 for example, comes in no less than five pitches – two “Coarse” and three “Fine”!

As far as I know the ISO set is the only standard fastener range of all the common ones that is neither consistent nor proportional within itself. Although it may work industrially perhaps it is this clumsy, bureaucrat-led approach that may be the real difficulty in making our models just right.

Nigel Graham 2.