Hello all ,

on a nice easter sunday I made a test ride with my fire king to see how the turbulator work.

Last year in october I saw the performance and made the subjectiv rating that it is a remarkable improvement.

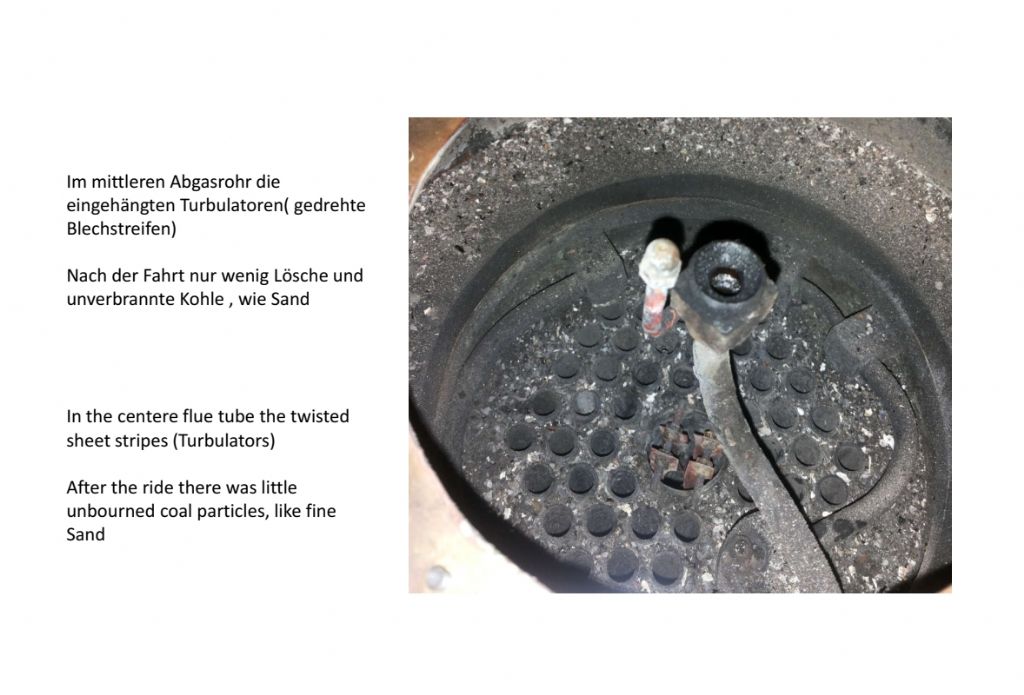

The added turbulator in the center flue tube.

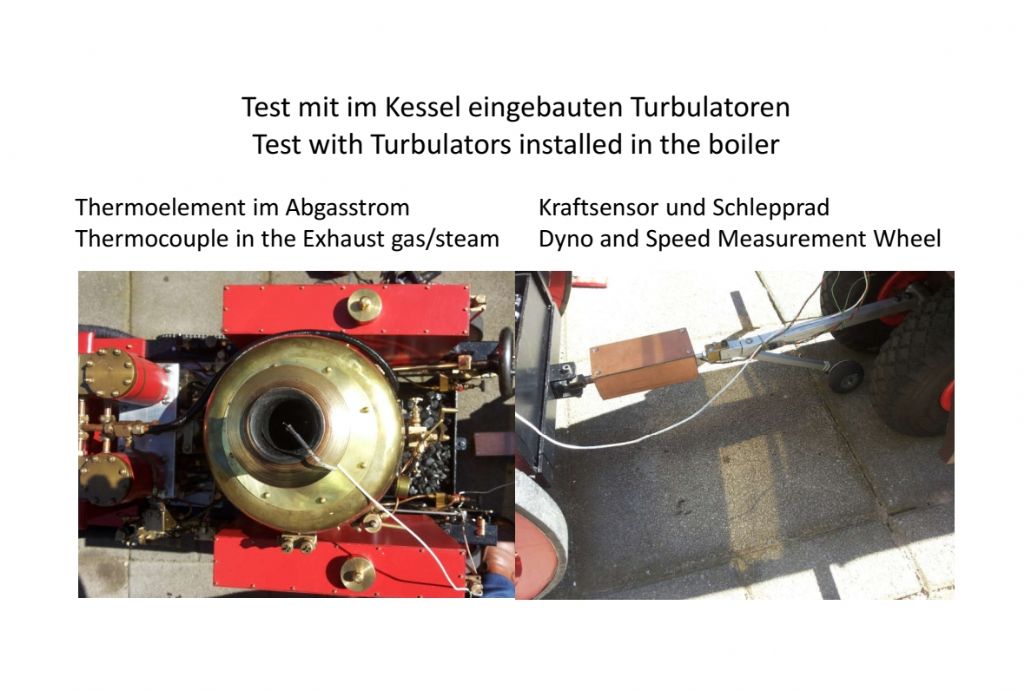

This time I added measurement equipment to see the exhaust temperature, the pulling force and the speed.

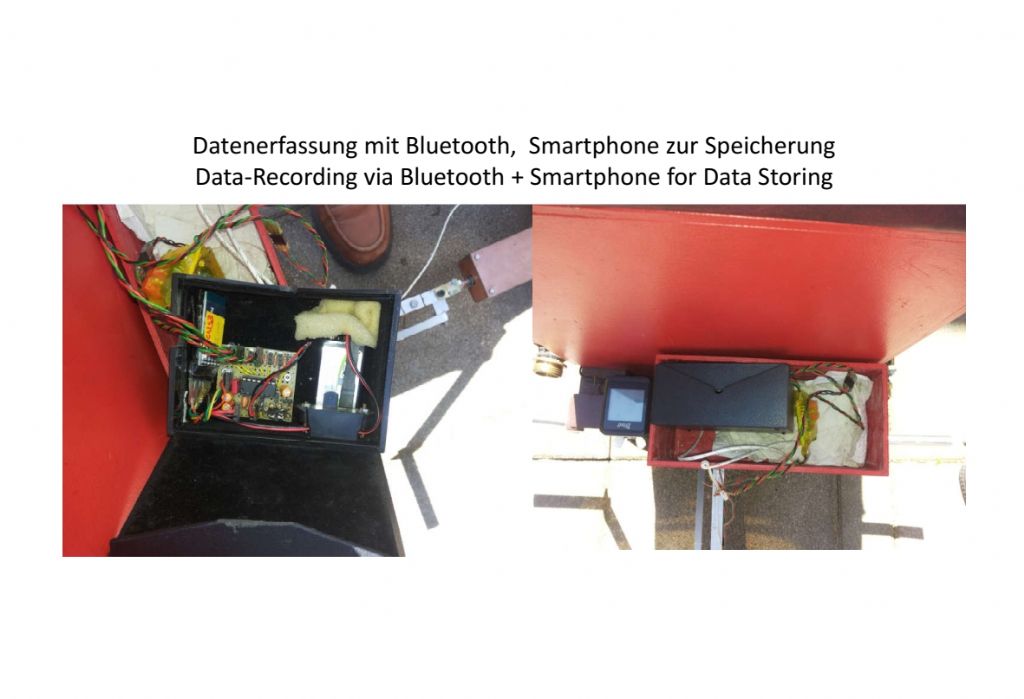

I recorded this by my own software via bluetooth with a smartphone.

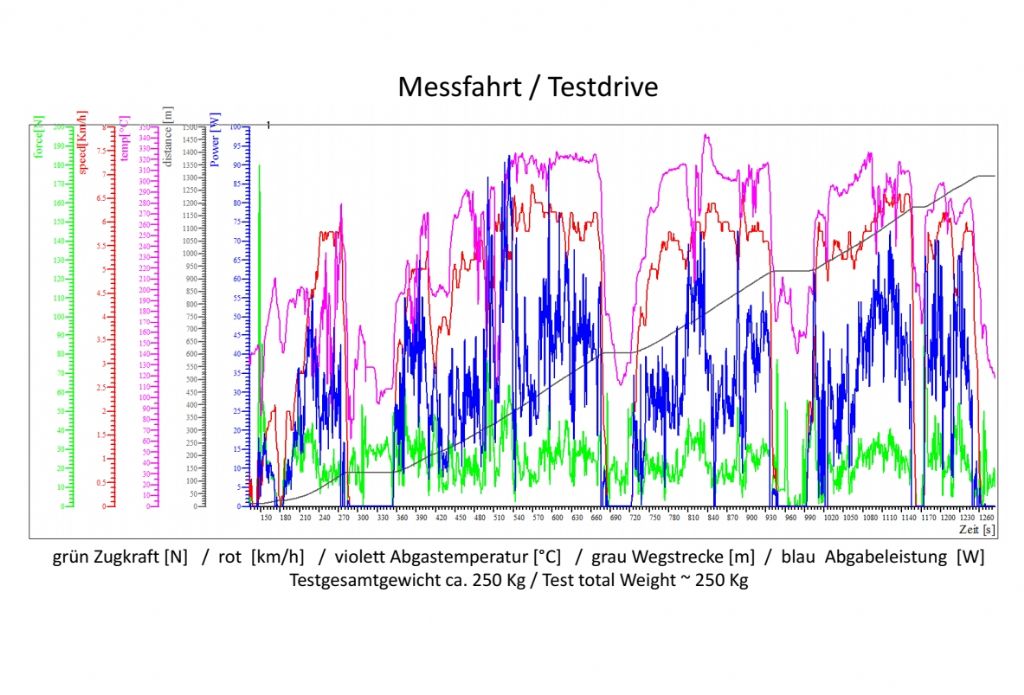

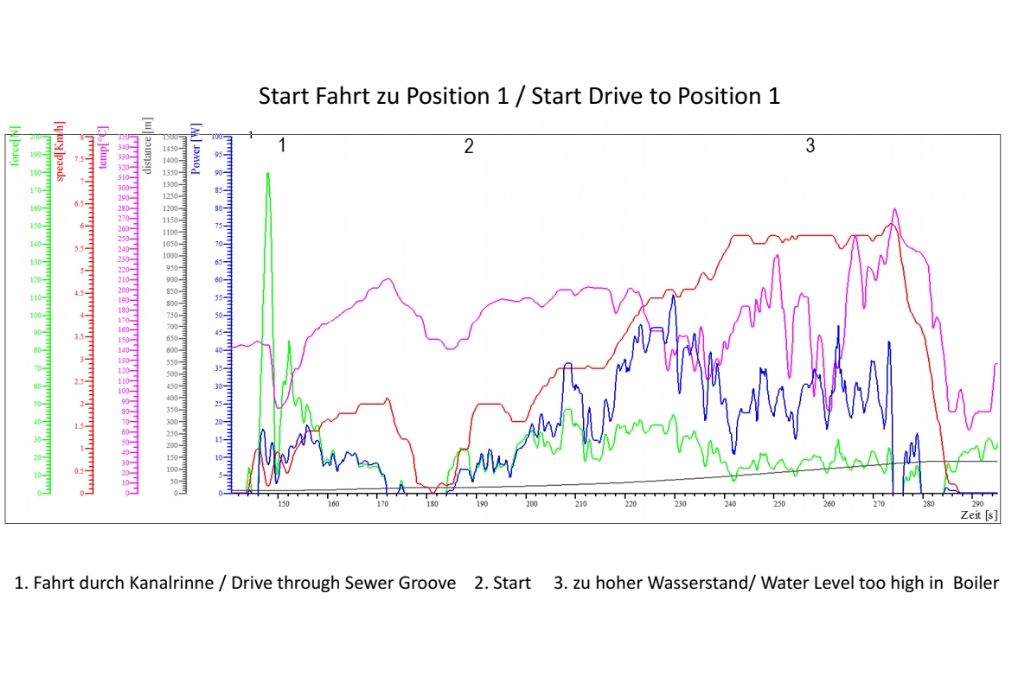

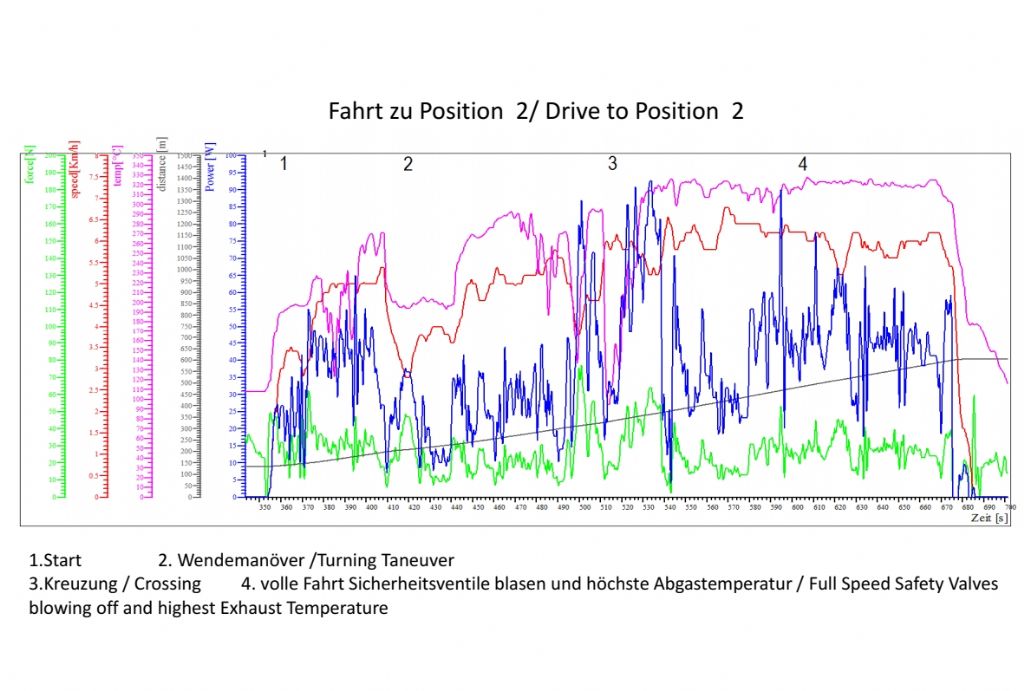

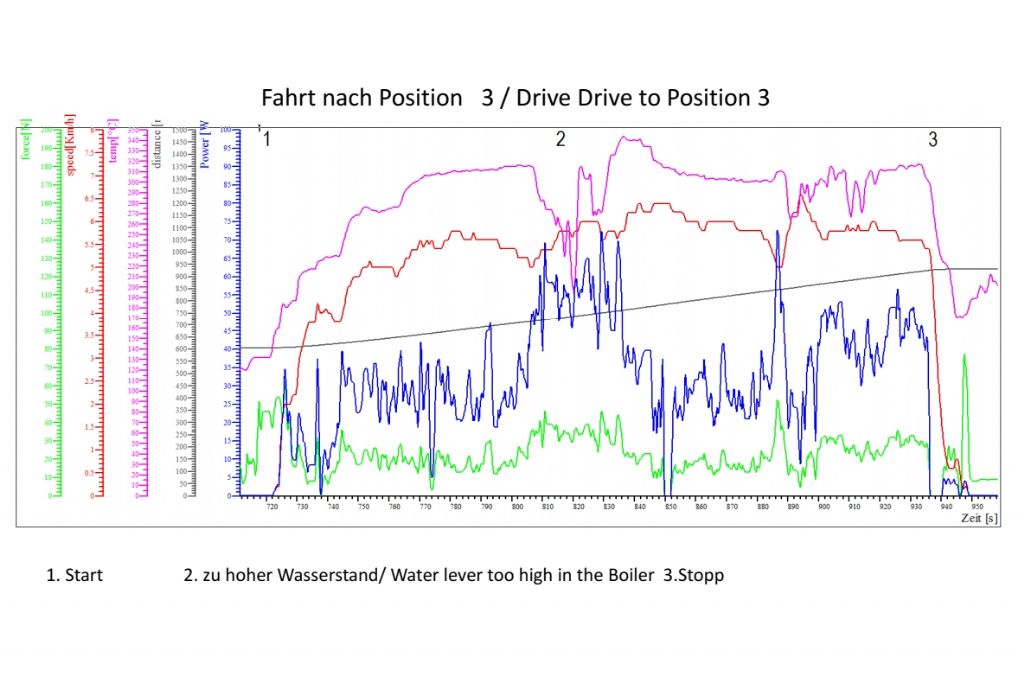

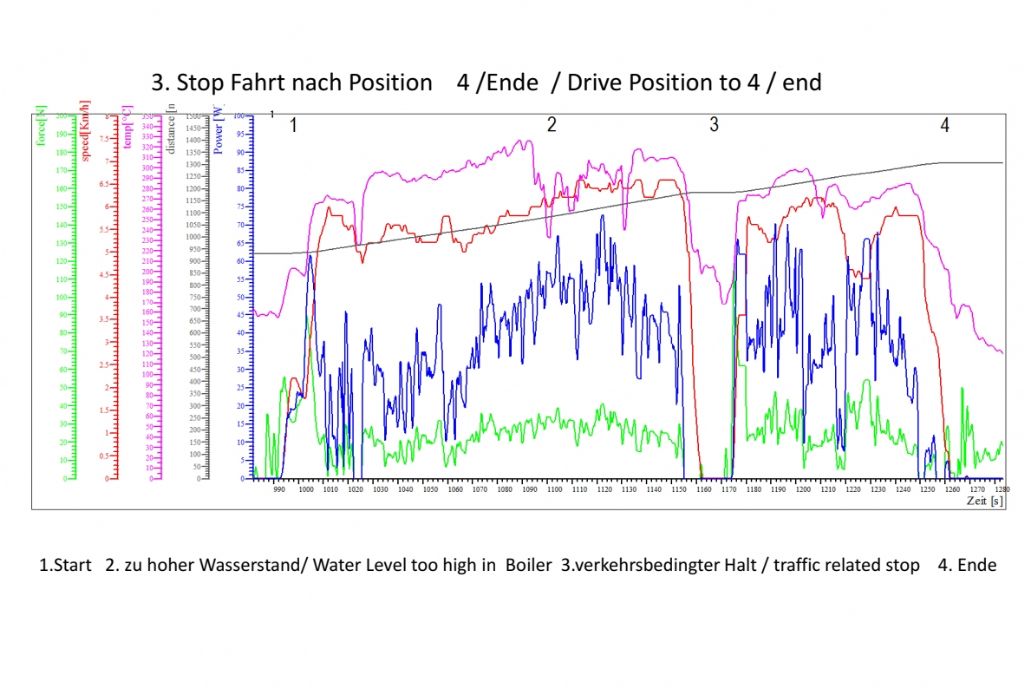

The colours are green the pulling force max 200 N, red the sppeed max 8 Km/h, violet the exhaust emperaturemax 350 °C, the calculatet distance in grey max 1500 m and blue the calculated power max 100 W

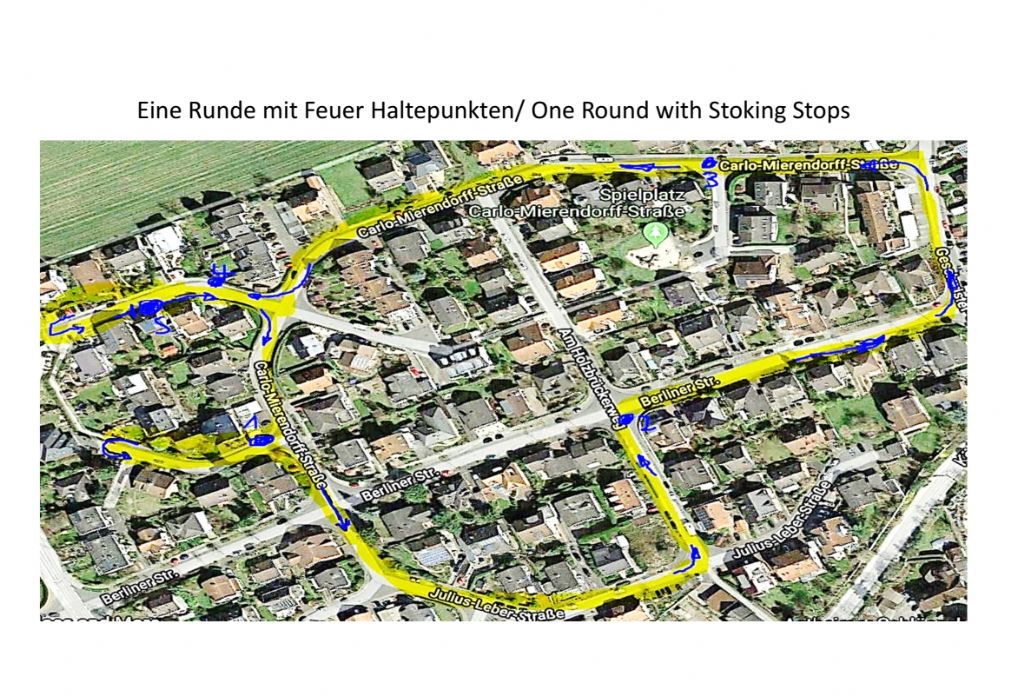

To show the measurement more in detail I devided it in parts. And marked the parts in a road map.

The fllowing diagrams are related to the parts marked in the map.

The ride over the pedestrian way into the street there was a peak force of 180 N . In 2 the journey starts.

The violet down peaks are related to the cold steam engine and a high waterlevel.

At Position 2 I filled the grate with coal nearly to the fire door. And then I start driving. In 3 I had to look to traffic and slow down a little. And then I was in full motion the boiler had lots of power an nearly constant 330 °C exhaust temperature and I was able to hold the speed legal speed of 6 km/h.

The same I made at position 2 I filled the boiler grate with coal and looked to the oil pump.

In 3 on my way back home I had to wait and made a traffic related stop. On my way the safety valve blew very often and I tried to pump water to come down with the pressure. I drove the round as fast as possible to see what happens.

With this fast driving there is not much unbourned coal int the smokebox. With a vaccum cleaner it was an easy job to clean.

For me it was a great success to see how the fire king performs now. There were some little drawbacks . I forgot to weight the coal ,it was about 3 Kg and 14 liter water. The powersupply of my measurement equipment was only good for one round. The wiring of the sensors to the recorder have to be improved.

best regards

Werner

David George 1.

David George 1.