Good progress with the wheels. I thought I'd show some of my machining operations as I was using a faceplate for the first time. Any comments from the experts would be post appreciated. My idea was to build the whole assembly on a disc of aluminium which could be moved between the faceplate and the mill rotary table without moving any parts. This way I would (hopefully) maintain concentricity.

The outer rim was made from four strips of brass pinned and glued together:

Mounted on the faceplate I machined the outer diameter:

Then the inner diameter:

Because of the size of the rim I couldn't figure out how to machine the tyre groove on the OD, so I transferred to the rotary table and slowly milled the groove:

I also drilled the holed for the axles with the same setup. Then on the bench I could assemble the axles and the hub:

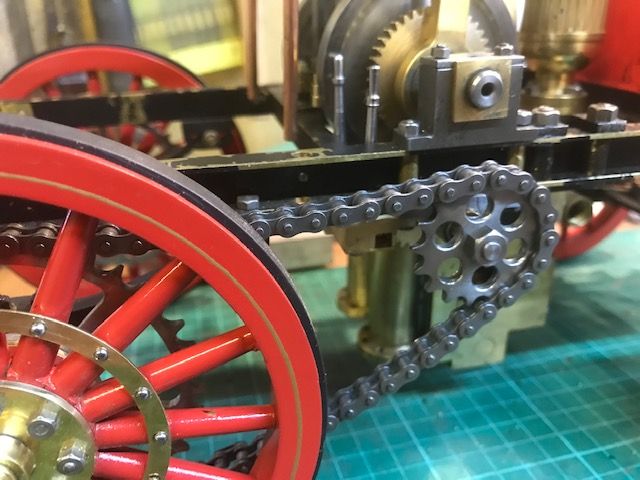

I was disappointed to realise that when I machined the tyre groove most of the pins I had put in to hold it all together had been nearly machined away and the whole assembly looked a bit flimsy. So I decided to add a brass tyre at the bottom of the groove and screw that in place. That seemed to work well, but it did reduce the depth of the groove from 8mm to 6 mm. Fortunately I already had the neoprene square section for the tyres and with a bit if experimenting found I could mill 2mm off the thickness – disaster averted. So here is one of the finished wheels. Not sure how to bond the neoprene tyre to the rim though. Any suggestions?

Bob

Bob Wild.

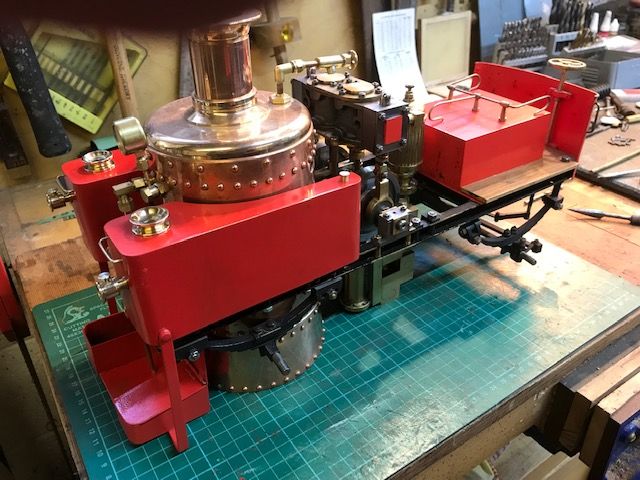

Your engine is very impressive Bob. Well done.

Your engine is very impressive Bob. Well done.