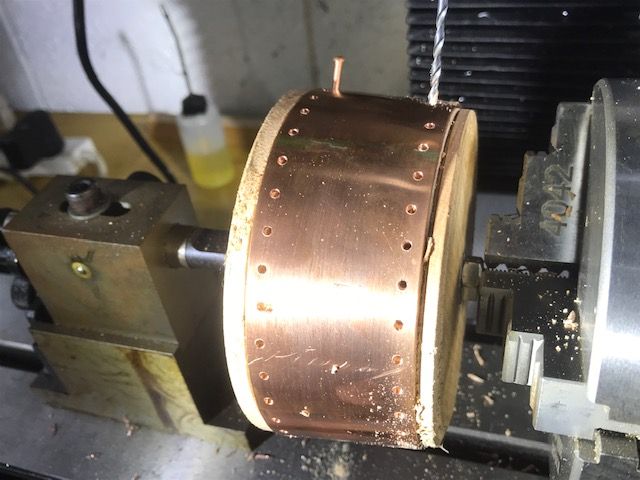

I said that I was a novice ! Made a lovely hardwood former to shape the lower tapered part of the boiler. Sawed off the excess overlap after bending and silver soldered the join after a fashion. Drilled two sets of 36 rivet holes at a 6 degree angle by tilting the head. Being a novice I completely forgot that the burrs from the drilled holes would dig into the wood. No amount of (gentle) tapping or prising would persuade the ring to separate from the former !!!

So as a last resort I decided to (hack) machine away as much wood from the former as I could to expose one set of rivet holes

The former is actually made from two pieces of 25 mm beach screwed together. So I figured that if I drilled four clearance holes in one piece and bashed four screws it was worth giving it a try to separate the two pieces to improve my chance of getting the ring off the other piece of wood.

And bingo, it worked. And finally the ring came off the former in one piece. Got to fettle it up and figure a way of riveting it to its mounting plate. That will be in a while since SWMBO wants to go off in our caravan for a while.

But it gives me an opportunity to think about how to fix those rivets. My inclination is to glue the lower ones in place since they are purely cosmetic and don’t hold anything. Especially as the annealed copper scratches even when you look at it.

When it comes to the upper mounting plate I thought about tapping the end of the rivet and bolting the ring to its mounting plate. The rivets are 3/32 dia which is only a nat’s whisker over 8ba. So a little skim on the end of the rivet would make this possible which would avoid any bashing to form a proper rivet. Any thoughts from you experts would be most appreciated.

Bob

Bob Wild.