Hi All

Final update ……

I retired at Christmas, so my job is now playing in the workshop !!

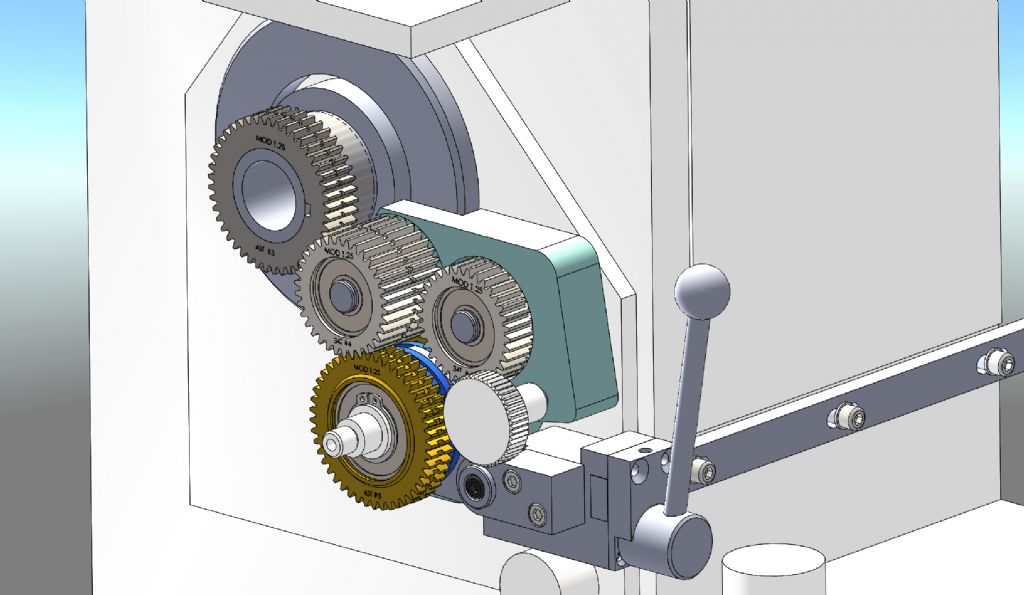

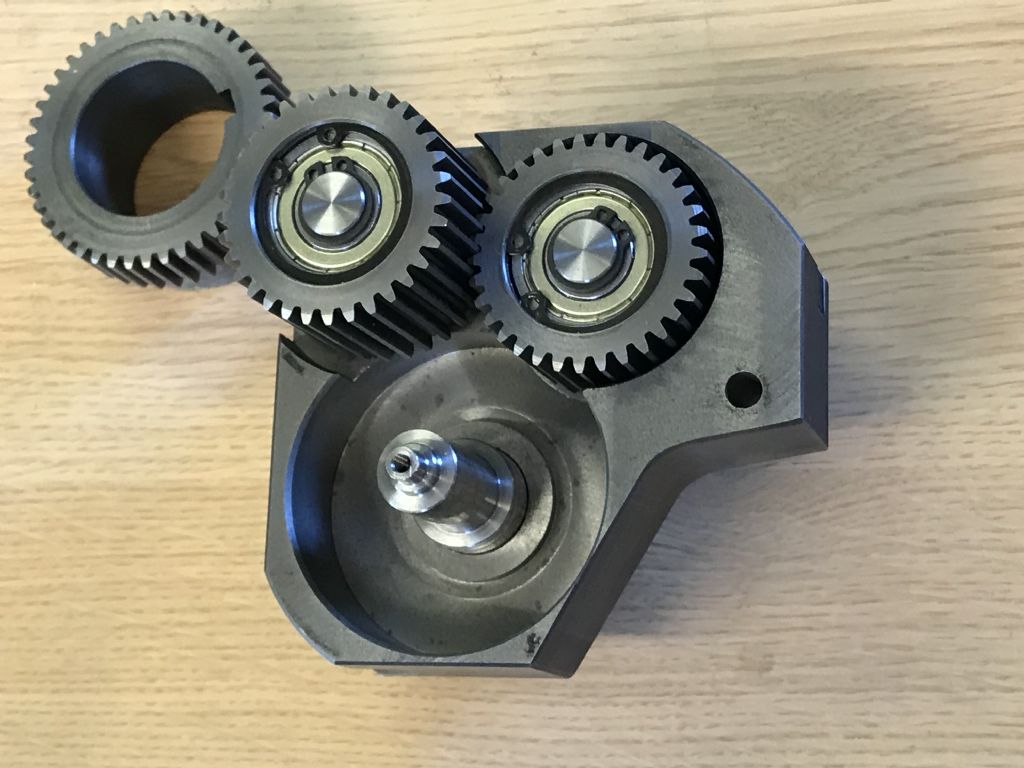

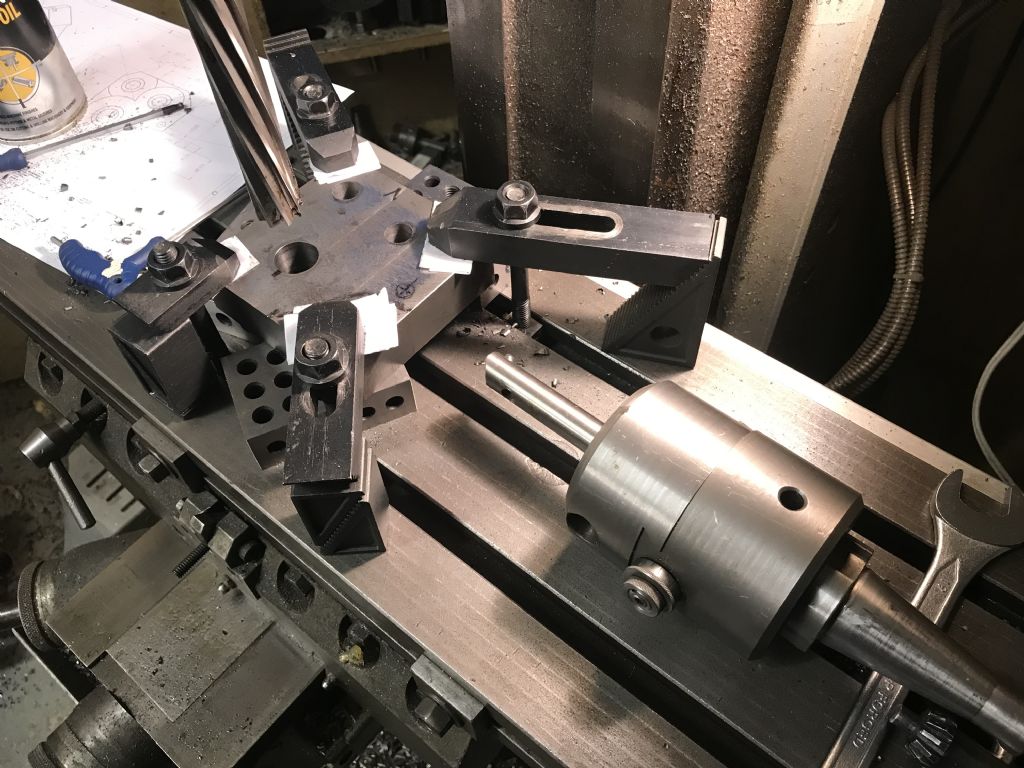

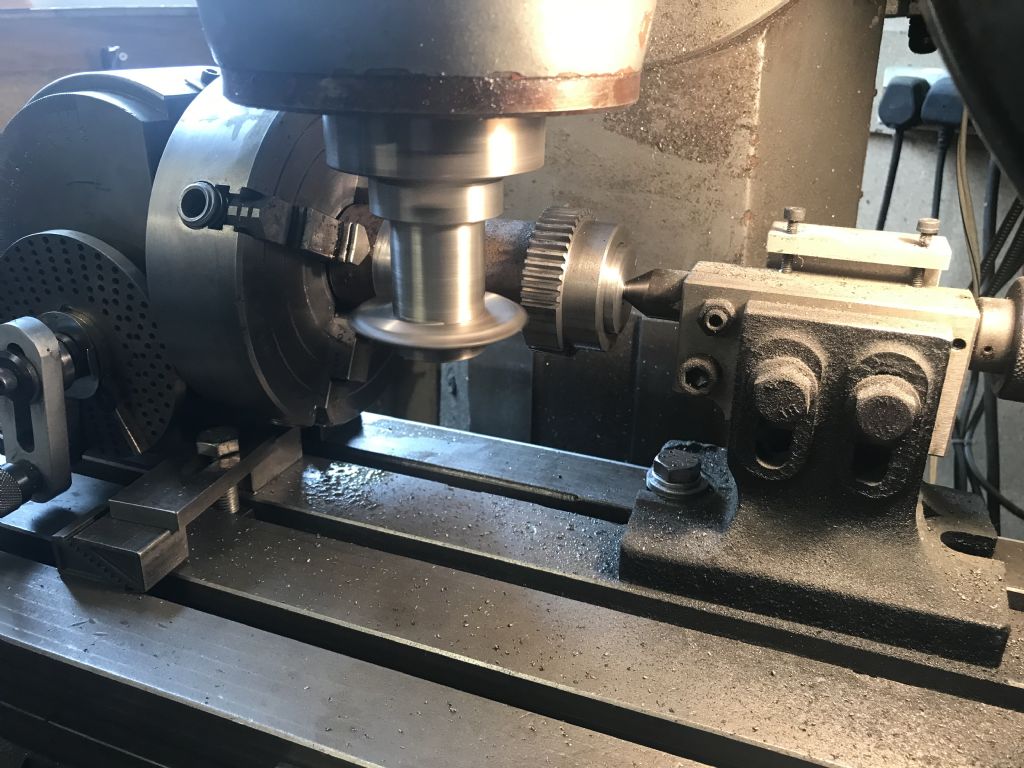

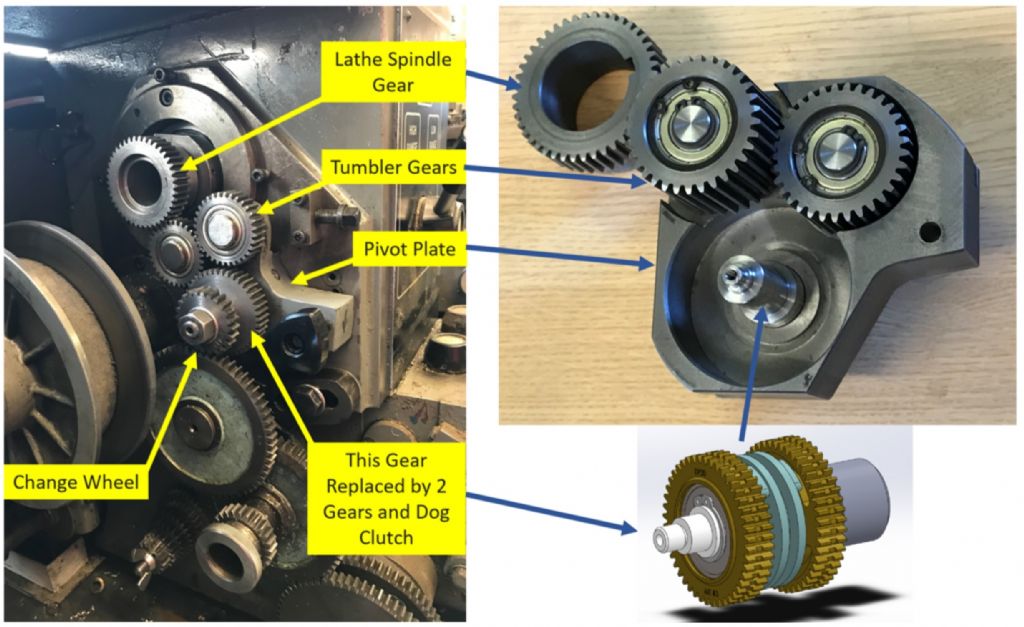

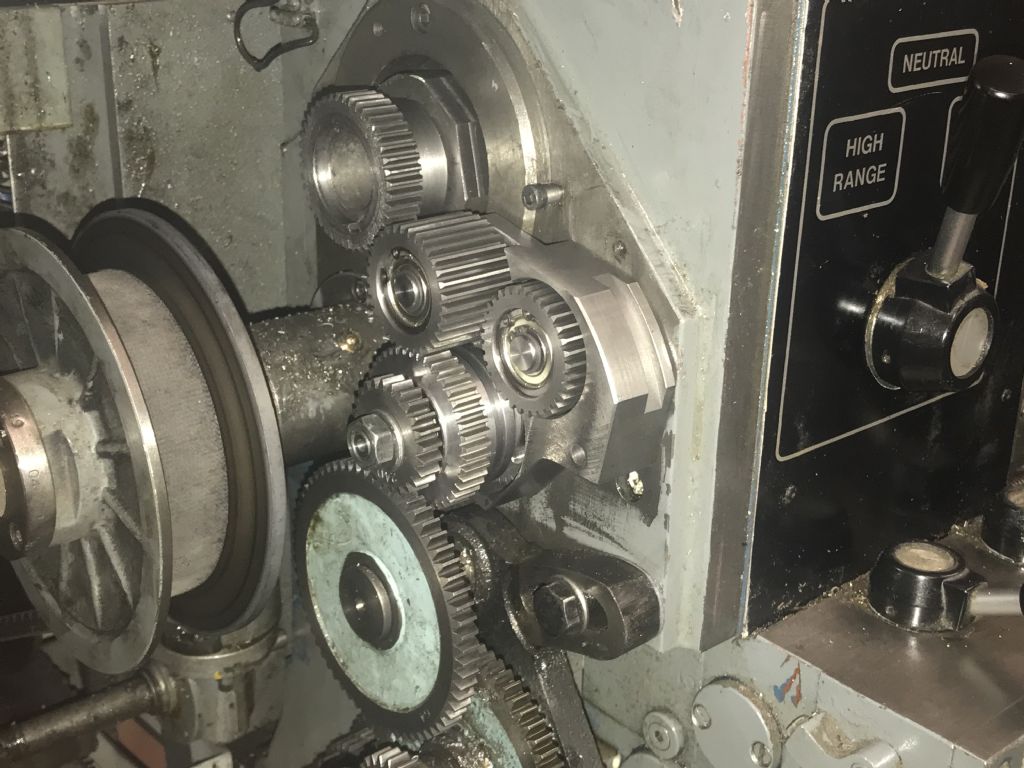

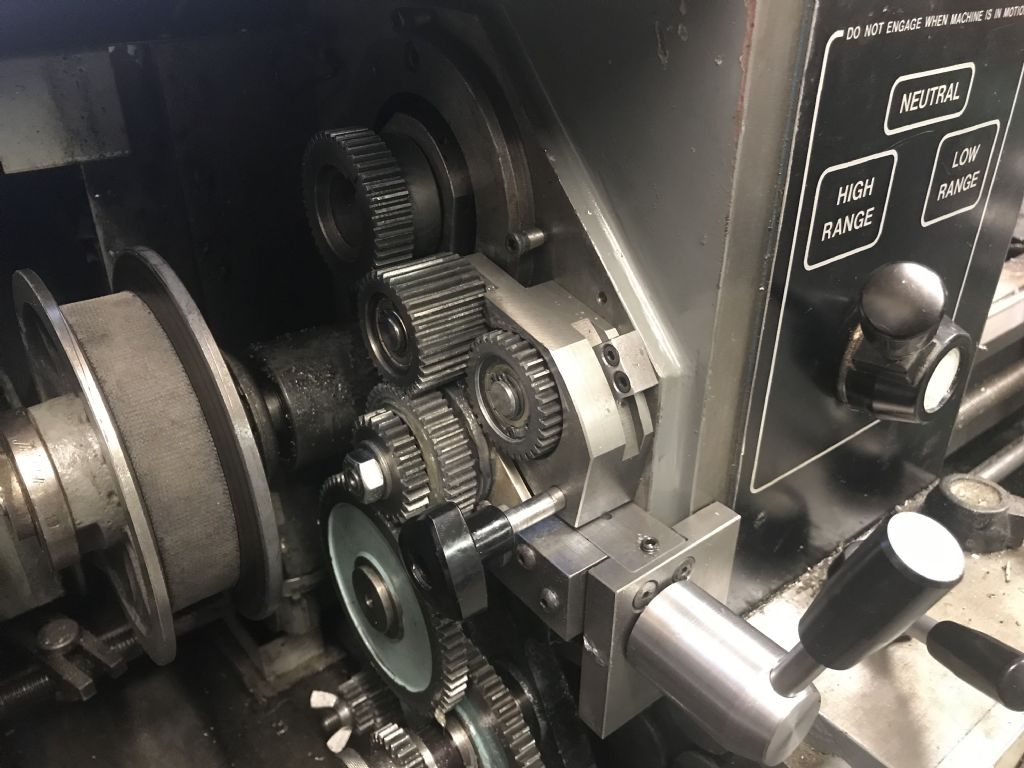

So I’ve blitzed the dog clutch that I started 19 months ago, and finally finished the complete system, with the saddle auto actuation being the last bit. But that’s it, done, and it works a treat !!

The lever system is a bit convoluted, but the saddle feed disengages the threading quite accurately, with a nice satisfying snapping action and a repeatability of few thou at low feed rate, which is great.

Screw threading at 500 rpm is less repeatable, but still reliably around 0.2mm, which is usable, but not sure I fully trust it yet at that speed.

Worked out a way that didn’t need any welding of the door, just an aperture cut out.

Only compromise is that the saddle has lost 50mm of travel at the Chuck end. I can’t say I ever remember needing to move the saddle that close to the headstock, but if required, I’d have to take off the lever. Not the end of the world.

So, next project is a CNC’d polarising flash filter holder for my son’s camera. Better finish the drawings – no time to waste 🙂

Cheers Will

Fatgadgi.