The answer, as always, to preventing and/or overcoming leaking joints lies behind the torch.

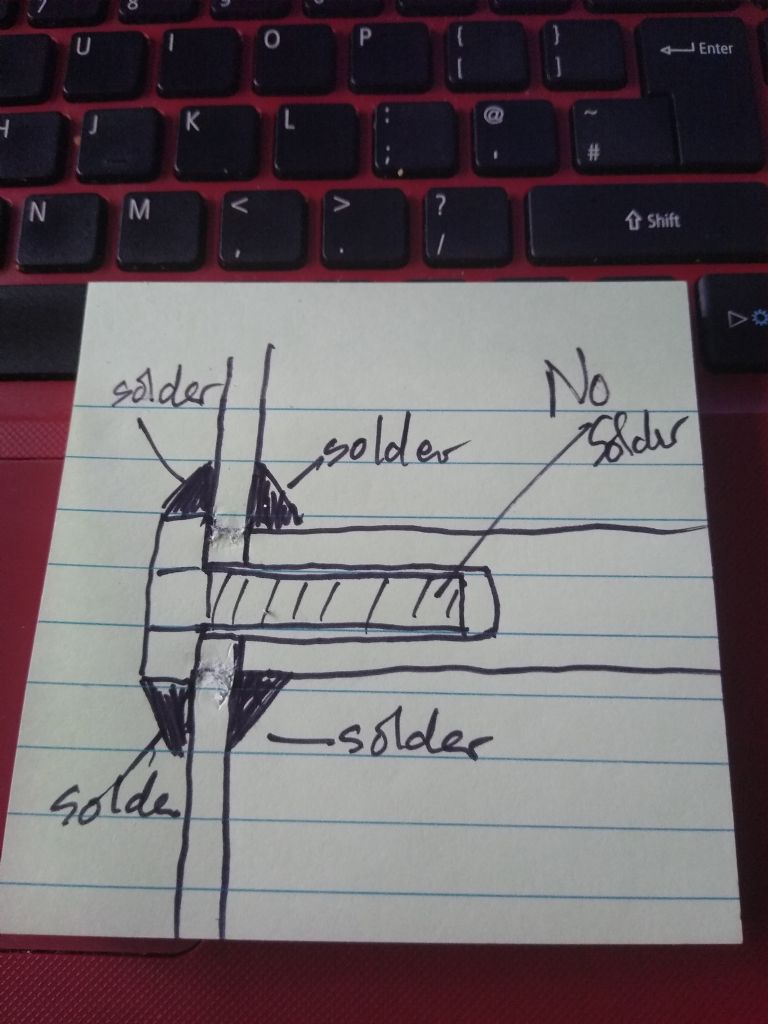

The basic principle of soldering and brazing has been ignored. If you achieve capillary flow of the solder, it will penetrate the joint. If you don't, then you will reach the situation as per the sketch where a superficial joint is made on the surface but a crack is built into the back of the joint. The joint fails as a result of a poor heating technique. Where a silver solder has been used, you can be sure that the joints have been made using a welding technique with an oxy-acetylene torch.

If in attempting to repair a leak you find another, is more evidence of a poor heating technique. The second, third, fourth……leak is developed in other weak joints created at the same time as the first.

It is virtually impossible to repair a leak in isolation. Leaks can be repaired. You just have to adopt a better heating technique. It can be done, it just requires a better heating technique and a little patience.

As in all cases, prevention is better than a cure.

For more information consult BS EN 14324 available for £220+ or get a specialist book from your supplier of brazing materials.

But bear in mind that if you decide to repair a silver solder joint with a soft solder that you are entering the"Last Chance Saloon" . If you don't succeed, some consolation will be obtained from the scrap price of copper.

Keith

PS. It's an excellent book – I wrote it!

Baz.