There are also a number of errors that could lead to the beginner to have to remake some parts. Not having got the last part of the article yet, I have made up the crank and some other parts using what material/sizes I had.

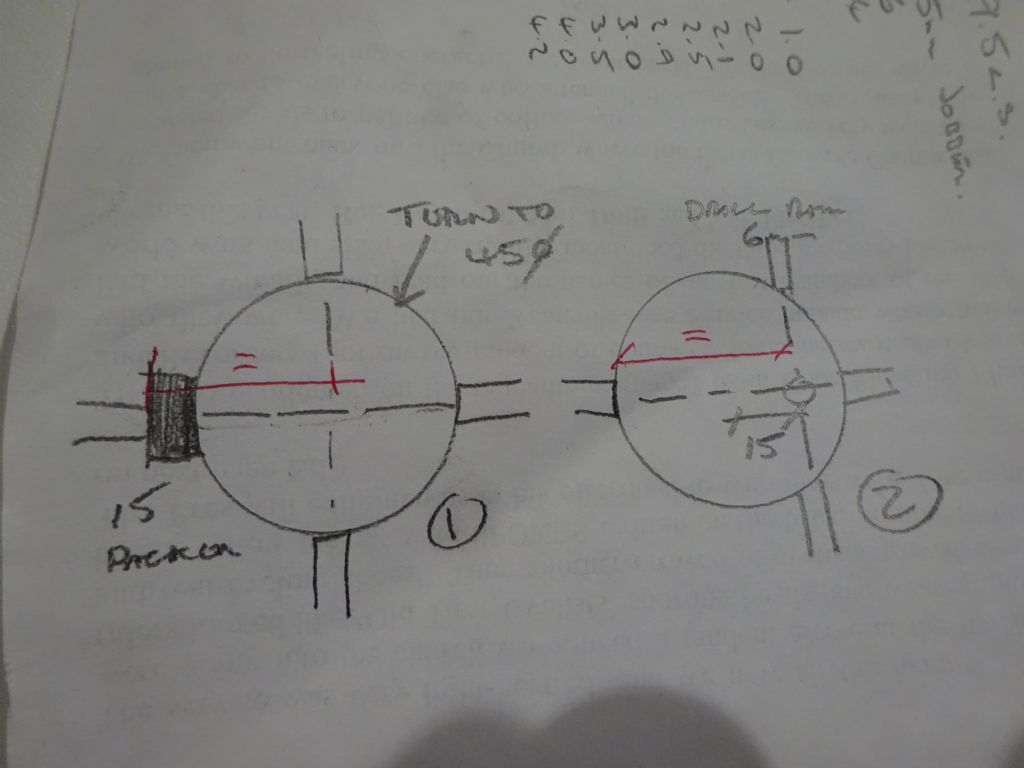

As the instructions for crank assembly were not available yet (to me!) I made the discs from 13/4 bar, turned to diameter and centre hole drilled and reamed, then transfered to the mill/drill to drill the offset holes( I have cheap dro's on the mill)

A pet hate of mine is when the auther says he used various bits of scrap lying about in the workshop rather than having to go out and purchase same. I nearly died of heart failure when I priced up 6mm brass sheet!!!

I did not particularly like the method of cylinder construction so made mine out of 25mm hex bar, only parts left to make now are the end caps for the cylinders, otherwise the engine has been run in as is by driving the main shaft.

Next step is strip down, clean, reassemble and try putting some air through and see what happens. Interesting but enjoyable build at my level of competence(quite low I must admit), and managed to spot the mistakes before parts were ruined. I did manage to get hold of the original ( middleton v4) construction notes which helped fill in some of the gaps while waiting for the magazine to catch up.

Eric Cox.