Without wanting to hi jack Fred's thread, have been thinking about Roger's model of a Marshall, and Tim's comments.

Tim is right that the early two strokes relied upon a "Harmonic" exhaust system to scavenge the combustion products from the cylinder, and to partially charge it.

Because this relied upon the exhaust system being in resonance, the engines were virtually constant speed units, to stay close to the resonant frequency. Anyone who has heard a Marshall two stroke running will testify to this

A model of a Marshall, running at 2,000 rpm, will sound anything but prototypical!

The dynamic magnifier curve is extremely "Peaky", so that a comparatively small deviation from the resonant condition can result in the loss of the advantage. What works well at 2,000 rpm may do nothing at 1950, or 2050 rpm. Witness the need for speedway and motorcycle racers to stay "on the meg".

Similarly, at 1,000 or 4,00 rpm the system may do just the reverse of what is needed, as the engine and exhaust pulse are then completely out of phase.

The resonance depends upon the speed of sound under the temperature conditions prevailing in the system, but that, unlike the components, cannot be scaled.

So to have an engine that runs in any way like the prototype, there will be the need to depart from the original.

It may be possible to lengthen the exhaust tract, and yet apparently stay with a prototypical looking "silencer".

A 1/6 scale model would need the exhaust system to be six times as long, as scale, to reproduce the conditions of the original.

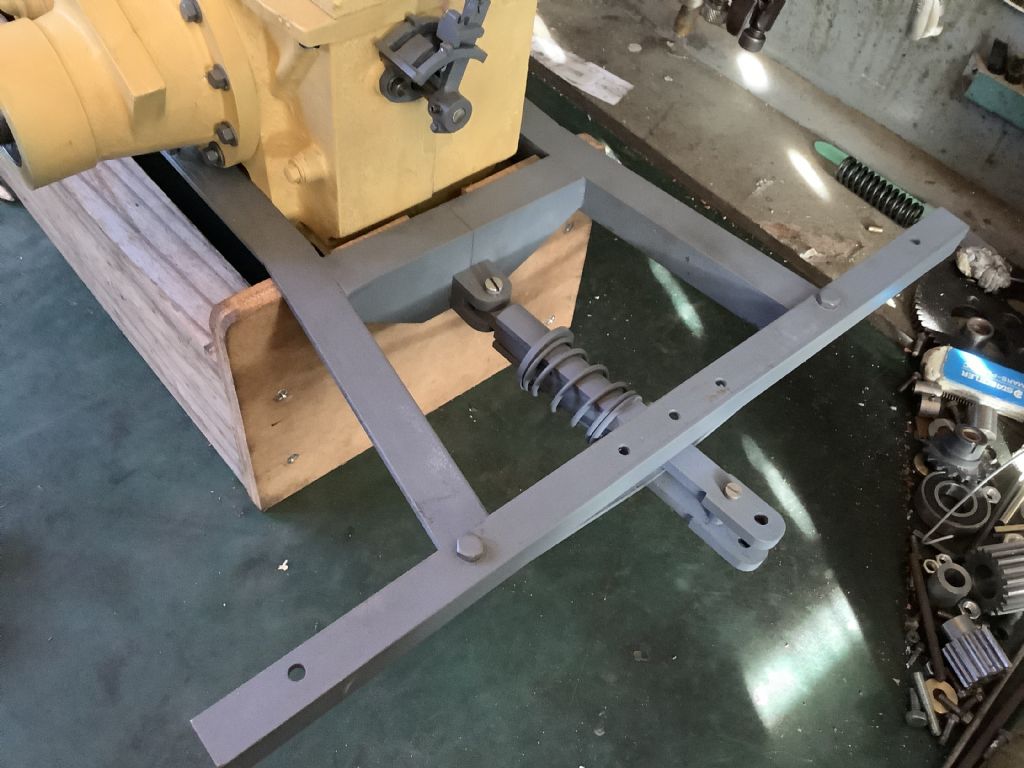

It MAY be possible, but not easy, to fold the exhaust pipe into an extended coil. and site it within the "silencer" outline, so that actual length is possibly three or four times the apparent length, whilst keeping the divergent- convergent external form.

Just a suggestion..

Howard.

Andy_G.

Andy_G.