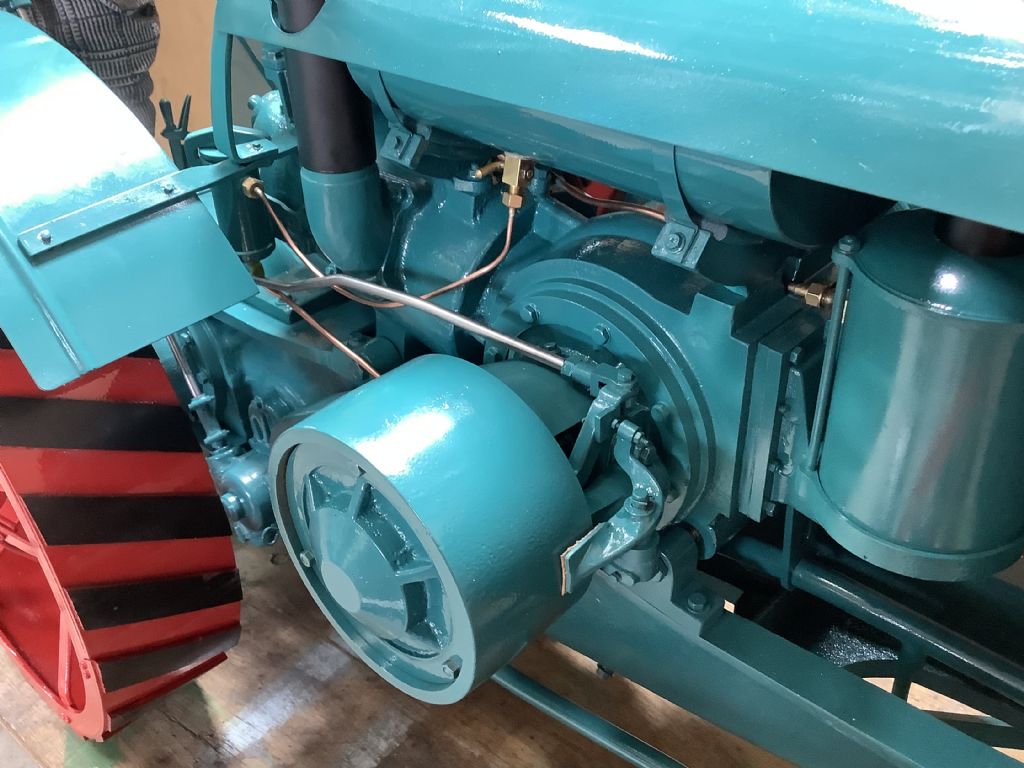

Mc Donald Model tractor

Mc Donald Model tractor

- This topic has 358 replies, 35 voices, and was last updated 11 March 2023 at 10:46 by

Andy_G.

Andy_G.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Myford Super 7 restoration problem.

- Small horizontal mill – capabilities?

- Dodgy car parts a new low

- Stuart Twin Victoria (Princess Royal) Mill Engine

- Tensile Strength Machineability

- Anyone know about wells and Victorian plumbing?

- Lady Stephanie

- leftover gear oil uses?

- Some help with a Cowells speed controller needed.

- Drummond round bed