I mentioned a little bit about my diesel at the start of this thread however things have moved on. I have been experimenting with fuel injection for some time and have successful manifold injection systems for Petrol/Gas/Benzin. The diesel injection system appears to reach around 100 Bar but good atomisation is proving difficult. The initial engine was a horizontal two stroke based on the Field Marshall design.

The two stroke diesel would start and run on standard automotive diesel fuel. I believe that an amount of the running was on fuel that had passed by the piston and was vapourised in the crankcase. This was backed up by the amount of oily black clag that comes out of the exhaust and the lack of response to the fuel rack position once it starts.

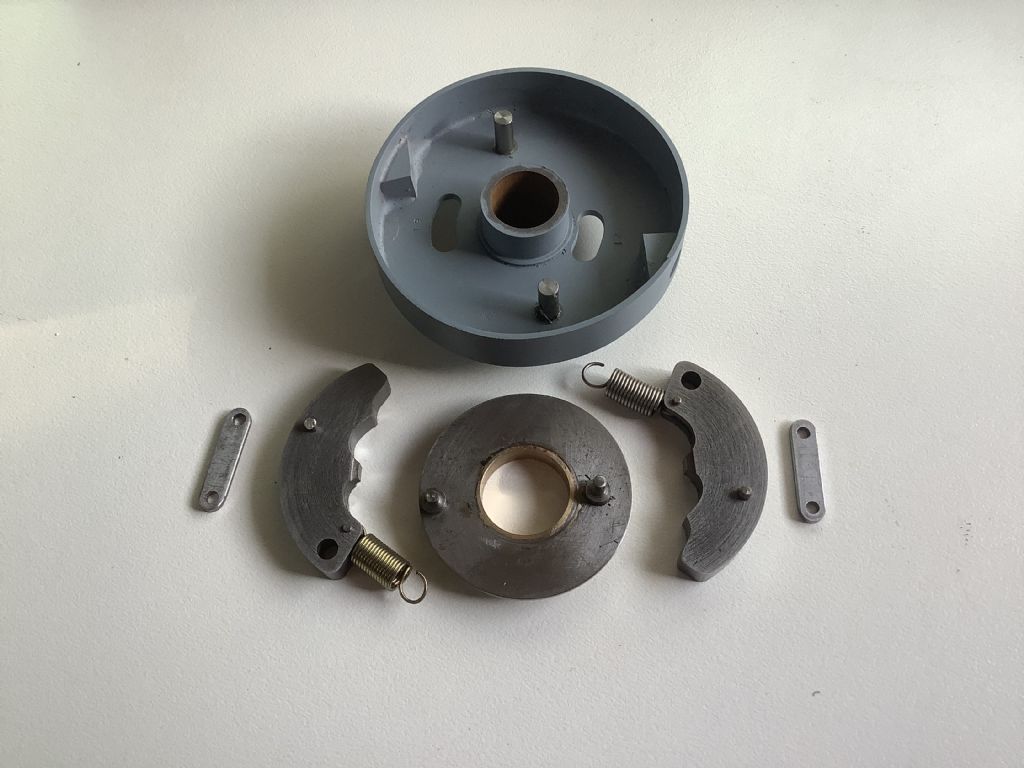

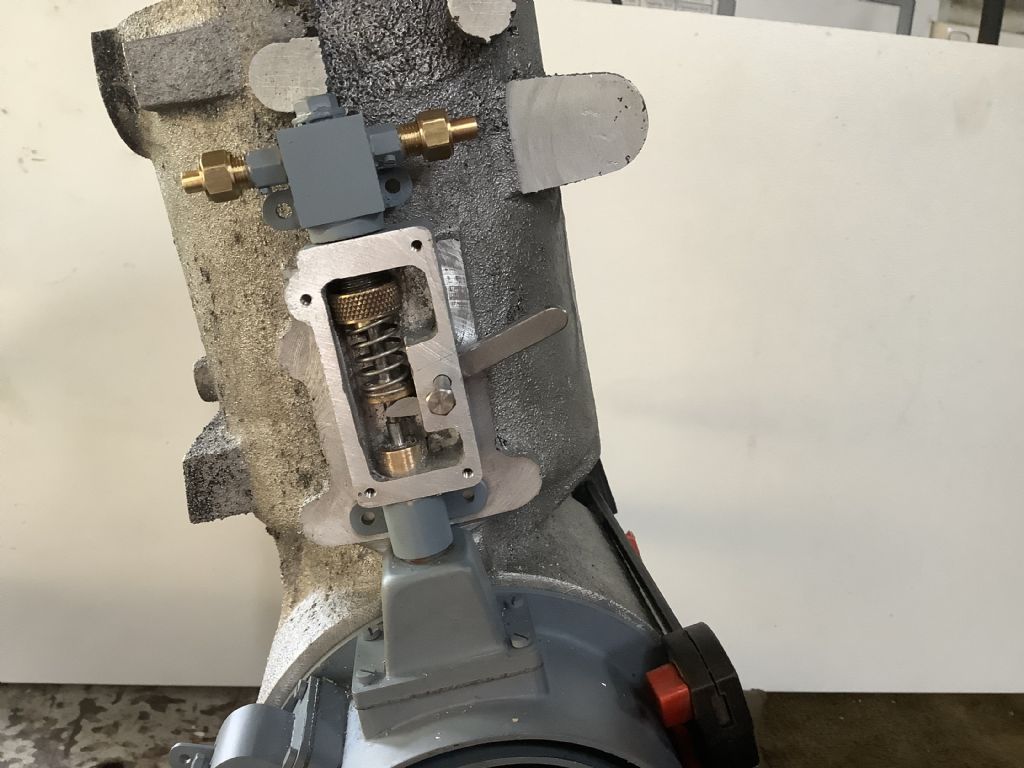

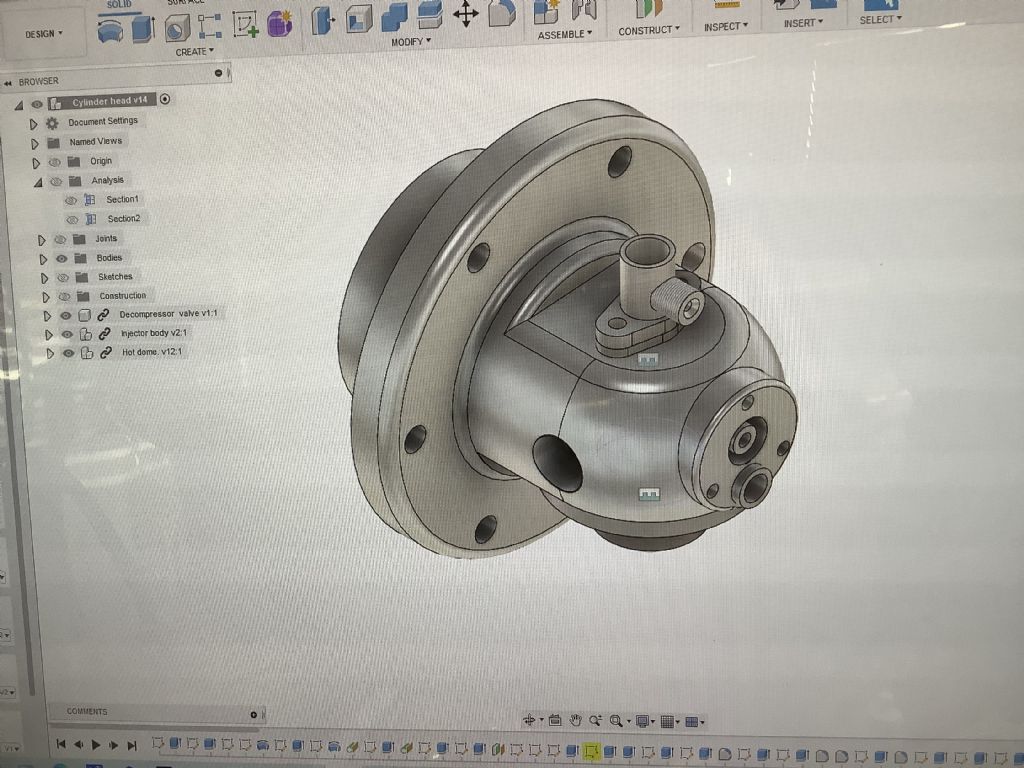

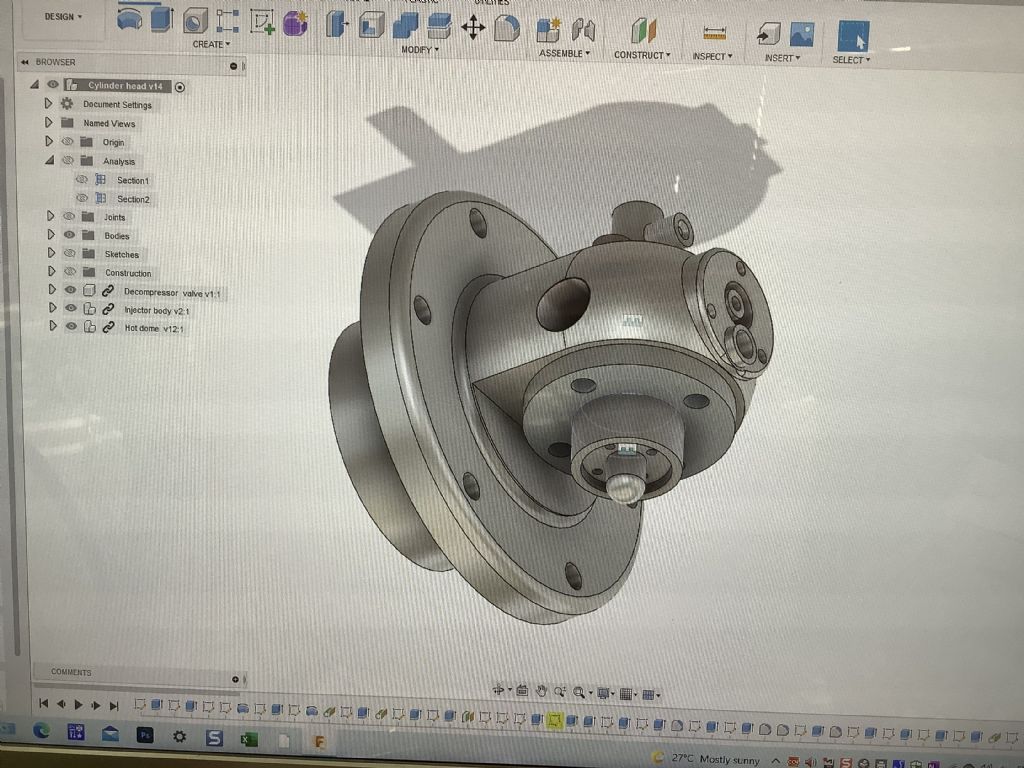

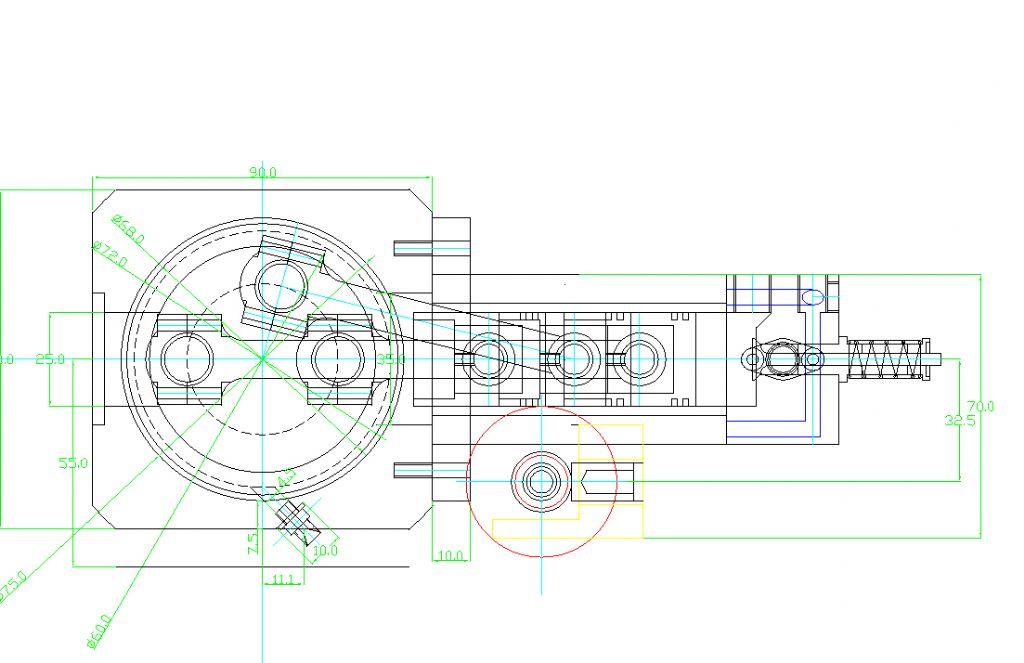

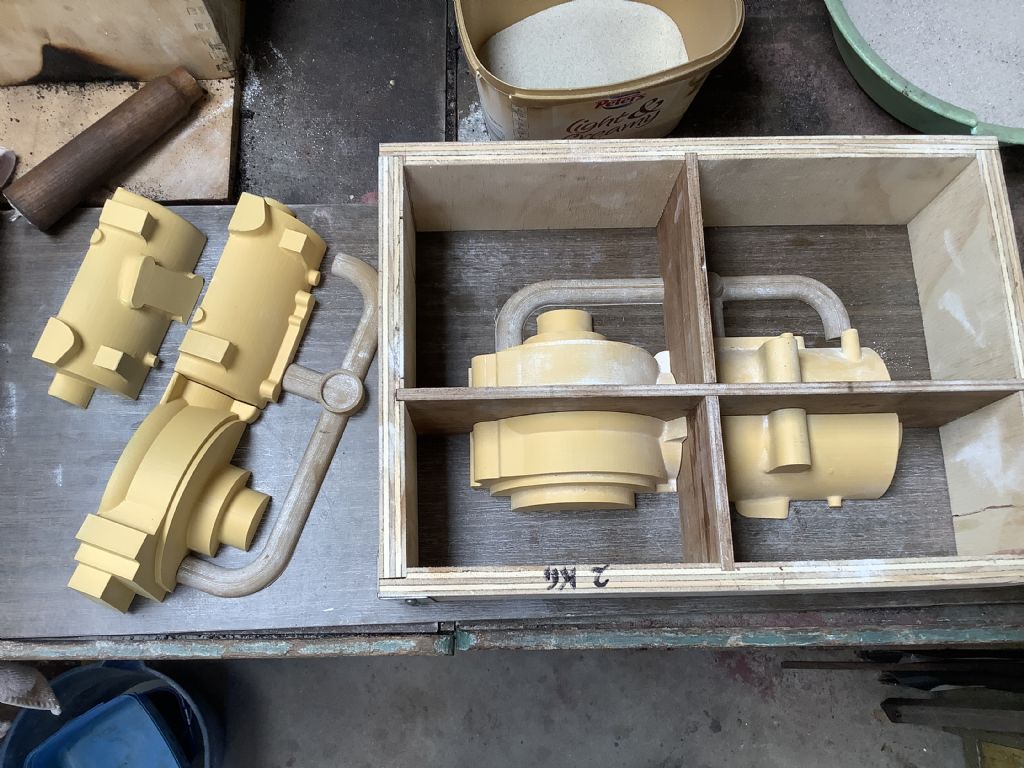

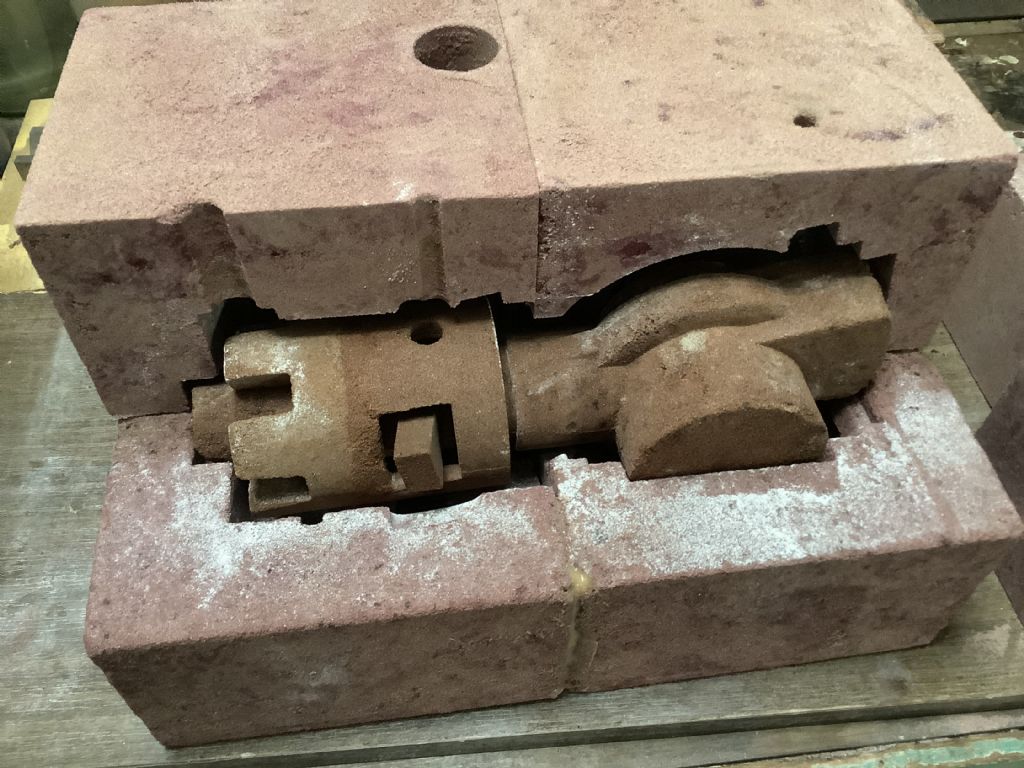

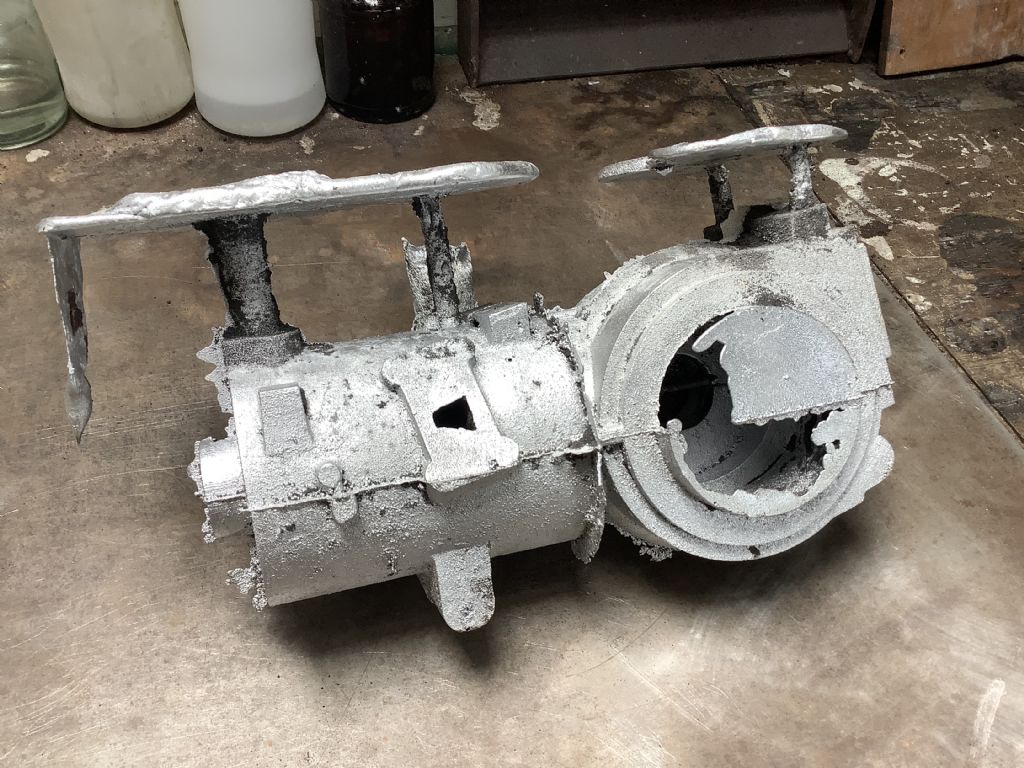

I am now rebuilding it as a four stroke to allow me to better separate the different parts of the operation cycle. The bottom end and conrod will be retained along with the lubrication system. It will need a new cylinder block piston and cylinder head. This is being documented on Model Engine Maker:

https://www.modelenginemaker.com/index.php/topic,10605.0.html

Here is a video clip of the two stroke nearly running and the initial layout of the four stroke. The stops were due to me reducing the fuel injection quantity. It has a tendency to run away but the air intake is easily blocked with a finger.

https://youtu.be/1OP6LxPb2uU

Andy_G.

Andy_G.