Hi Adrian R2,

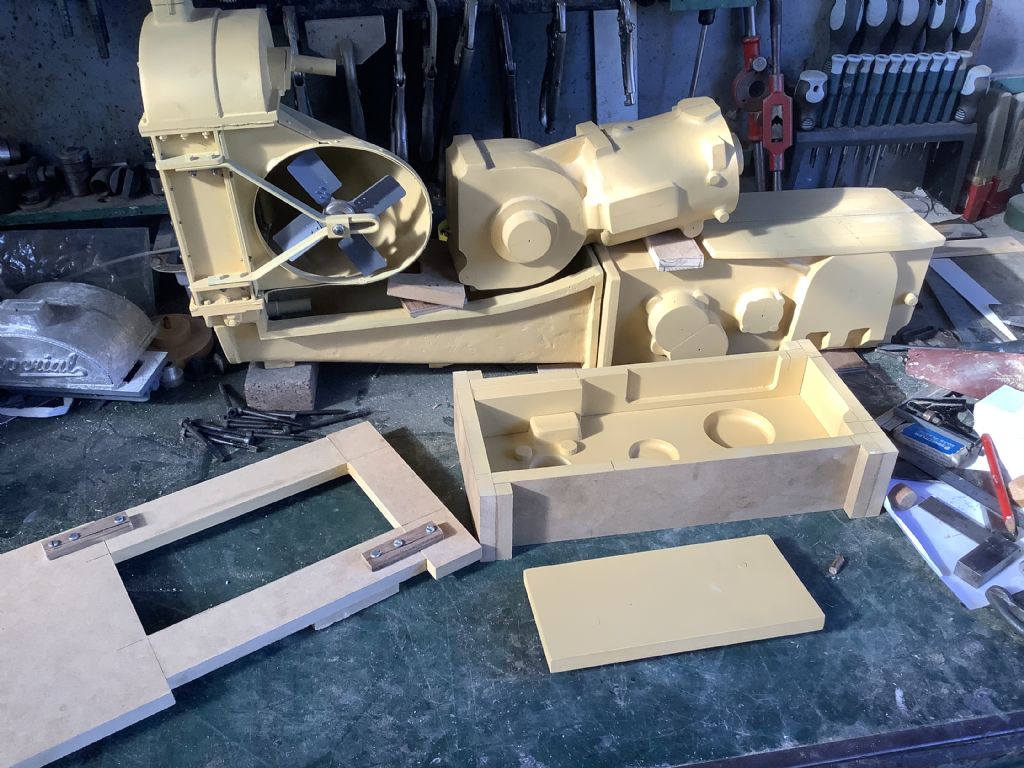

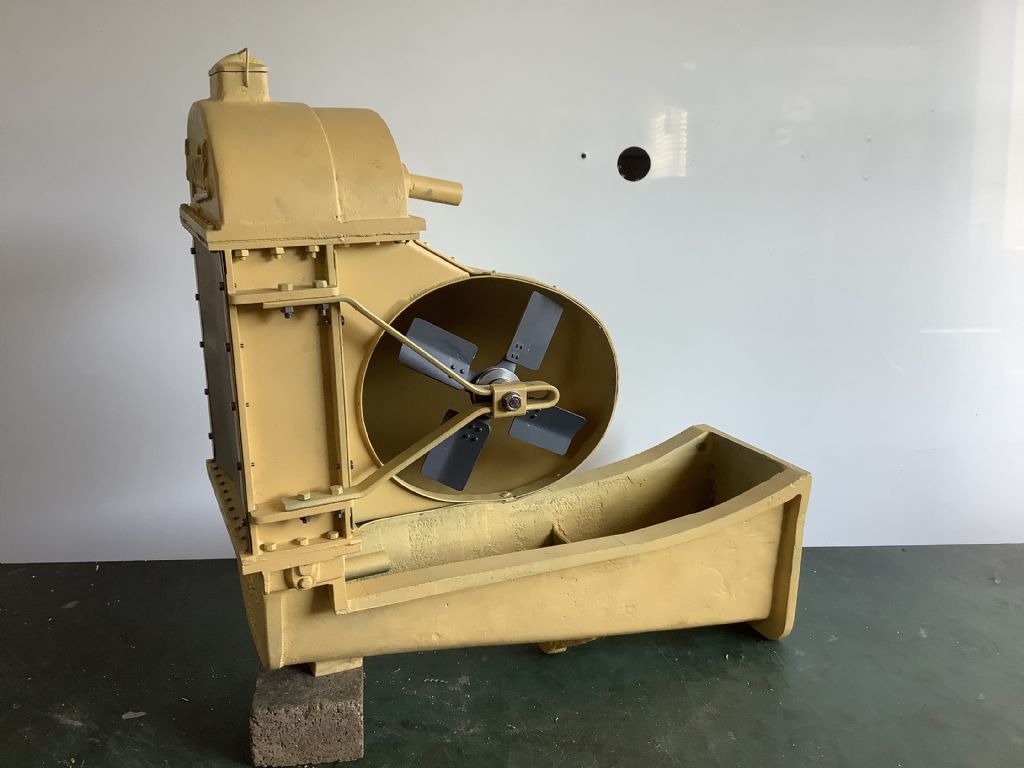

The photographs show my rather untidy foundry area of the workshop. The work bench has a sand storage area underneath, casting boxes above and a small cabinet on the left that holds the tools used in the process. The other photo shows the ‘hot’ area where I melt the aluminium using a gas blow torch. The fire bricks generate a vortex around the crucible. The scrap metal on the right is my stock of usable aluminium – Briggs and Stratton crankcase etc. I do use Coveral11 flux to clean the melt and degassing tablets to dive off any gas in the molten metal. I use both oil bound sand (Petrabond) and a local  white sand that I mix with a chemical binder/ hardener. Casting is an enjoyable process but it does take time and if you don’t succeed the first time you just try again !

white sand that I mix with a chemical binder/ hardener. Casting is an enjoyable process but it does take time and if you don’t succeed the first time you just try again !

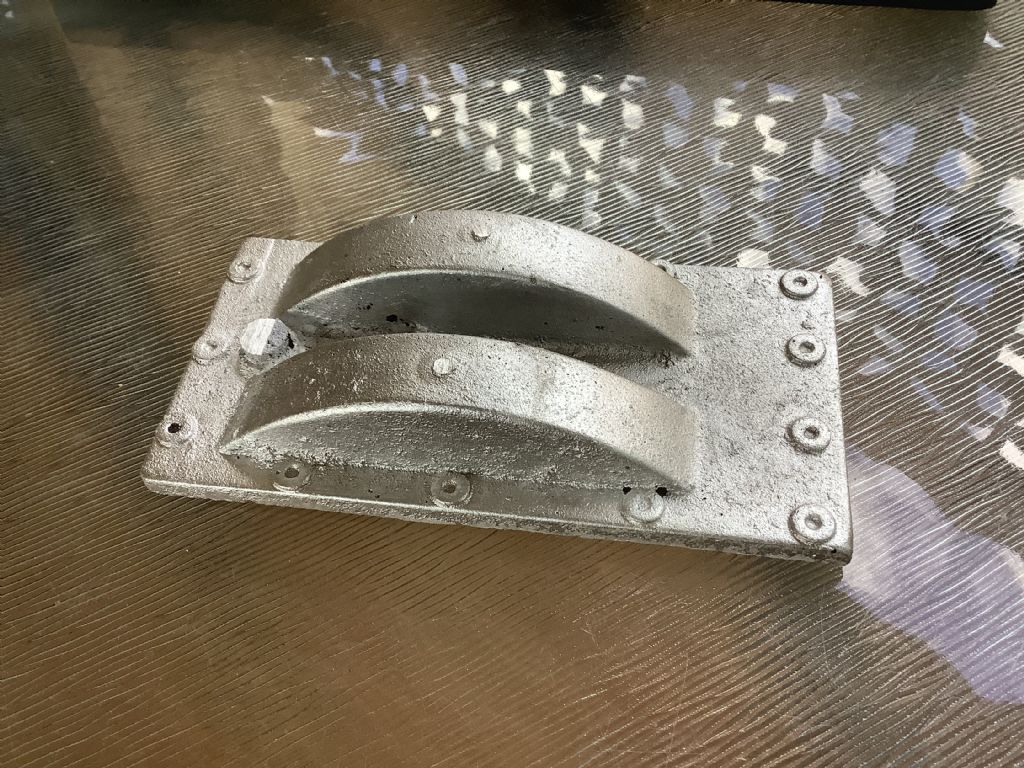

The half of the gearbox ready for assembly and casting and the pattern for the rear axle supports.

9

Andy_G.

Andy_G.

If I am reading under the radiator correctly it's an Australian maker. I thought that the single cylinder hot bulb/semi diesels were a European thing.

If I am reading under the radiator correctly it's an Australian maker. I thought that the single cylinder hot bulb/semi diesels were a European thing.