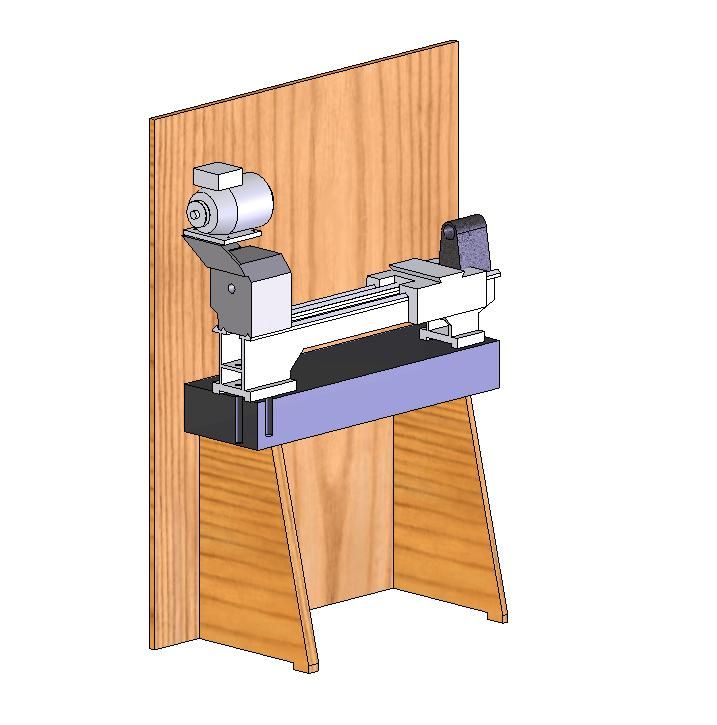

What you are looking for, in any stand, is rigidity.

It will be cheaper to make your own, but it does not need to be made from 20 mm steel plate.

The Eiffel tower is mostly fresh air, not solid steel

Even sheet metal, properly braced can be quite rigid. .Rear or side panels will act as diagonal braces in the plane of the flat metal . The bare framework may lozenge, but firmly fixing a sheet metal panel to it, transforms it into a deep girder.. Can you bend a 25 x 25 x 3 mm angle iron? You might bend a piece of 3 mm x 25 bar in one plane, but not in the other!

You can flex a plain cardboard box in one plane, but not in the other.

The stiffness of a girder is B x D^3 / 12, so doubling the depth increases the stiffness 8 times.

You might flex the panel across the 18 SWG plane , but you won't flex it in the other plane, even if it is only 100 mm deep.

So cupboard 800 mm high and 400 mm square, with the panels fixed firmly in place becomes a VERY strong girder, in all planes..

You drive around in a box made of sheet metal that is thinner than the steel used in the cupboards in the stand for the lathe, but it doesn't bend noticeably when you get in, or load a 50 Kg bag of cement into the boot.

The dash doesn't shake, or the doors unlatch, when you hit a pothole!

Howard

Dalboy.