My previous post on this forum solved one problem – minute hand slipping – the cure was to compress a star-shaped spring. Thanks for this advice.

But now there's aother problem. The clock movement was running well for three days continuously – I was regulating the pendulum length, while I could observe it running, before putting it back into its case. Then it suddenly stopped.

The cause was that there was no drive to the escapement.

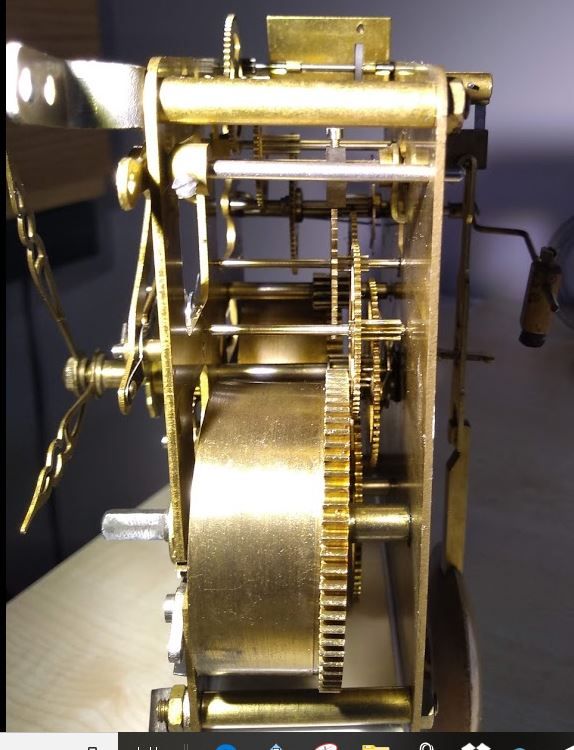

The gear that drives the escapement overhangs the large gear which contains the drive spring.

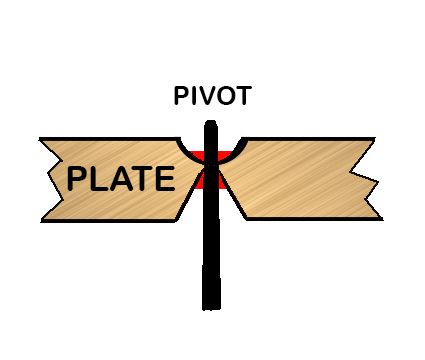

There is a small amount (approx 1mm) of end float in the bearings of this gear which drives the escapement. If it moves towards the front of the movement, it rubs against the large gear. The teeth on the smaller gear had snagged against the teeth on the large gear, and this stopped it turning. So there was no drive to the escapement, and the clock stopped. Nudging the small gear towards the back of the movement, freed it from its interference with the large gear – and the clock started working once more.

So my question is – how do I stop the smaller gear moving forwards and jamming with the teeth of the large gear?

Would tipping the clock slightly – so that the front is higher than the back – stop the small gear from moving forwards and jamming?

Any advice would be very welcome. I apologise for not using the correct technical terms – I am an engineer, but am only slowly starting to learn about clocks.

Chris Barrett 1.