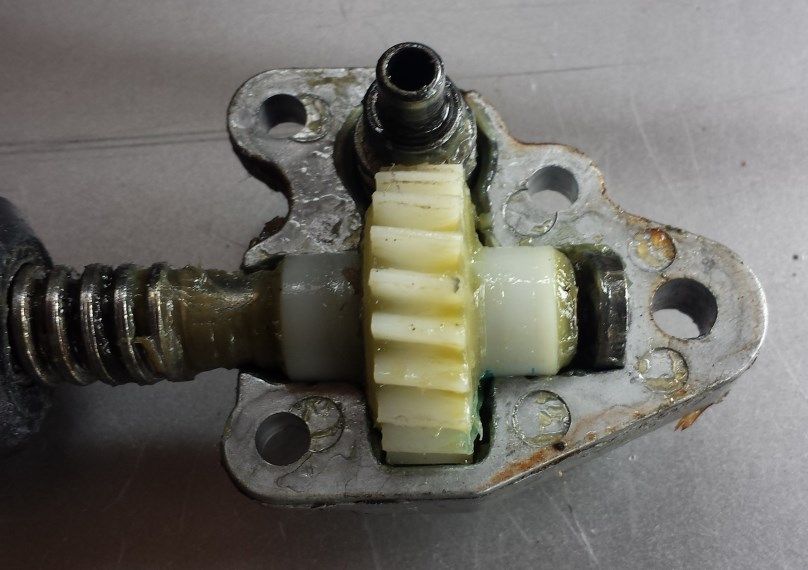

Maybe its the pictures but that gear looks wrong. It should not be flush with the top of the shaftthe shaft extends very slightly and there is a hardened button the top inserted ball bearing rests on.

I can see that wearing the casing out.

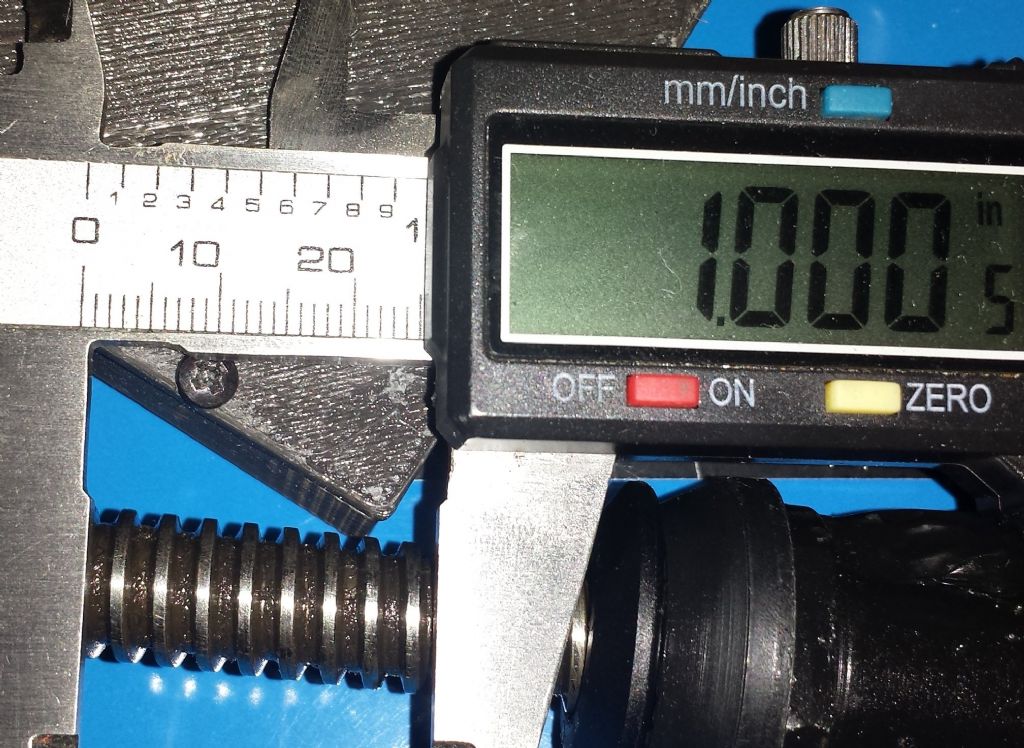

I couldnt find an 8TPI tap under 12mm diameter. 0.468 i think? I put that measurement in a previous post.

As Roger says, Its the journey i want to make one, I dont even need one its just something that i thought i could knock out quite easily. But it seems to be a bit of a learning curve.

Excuse to buy a mill though

Had to get some aluminium in because i didnt have anything over 25mm. Some 2" steel to make a holder/flycutter. An arbor to take an involute cutter (if the tooth pattern matches)? If not its the flycutter ( 90degree) not angled.

3D printed a U shaped holder for the gear. This is to test the theory and possibly used as a pattern to mill one or cast one. It may even be strong enough if i use light cuts?

It cost pennies to make and approx 3 hours so not a big loss if i break it.

Thanks.

PS.. Suggestions that doesnt include buying one.

Cut the internal thread or grind the shaft?

Tight fit and threadlock, or tight fit and threadlock and a small diameter pin at the top section not the botton as in the link above?

Suggestions please

Anonymous.

. Dashed my hopes of buying a tap and cheating.

. Dashed my hopes of buying a tap and cheating.