Posted by Tony Pratt 1 on 07/07/2022 15:20:15:

Posted by Graham Meek on 06/07/2022 11:07:06:

The front rake angle is the killer as regards a problem with digging in.

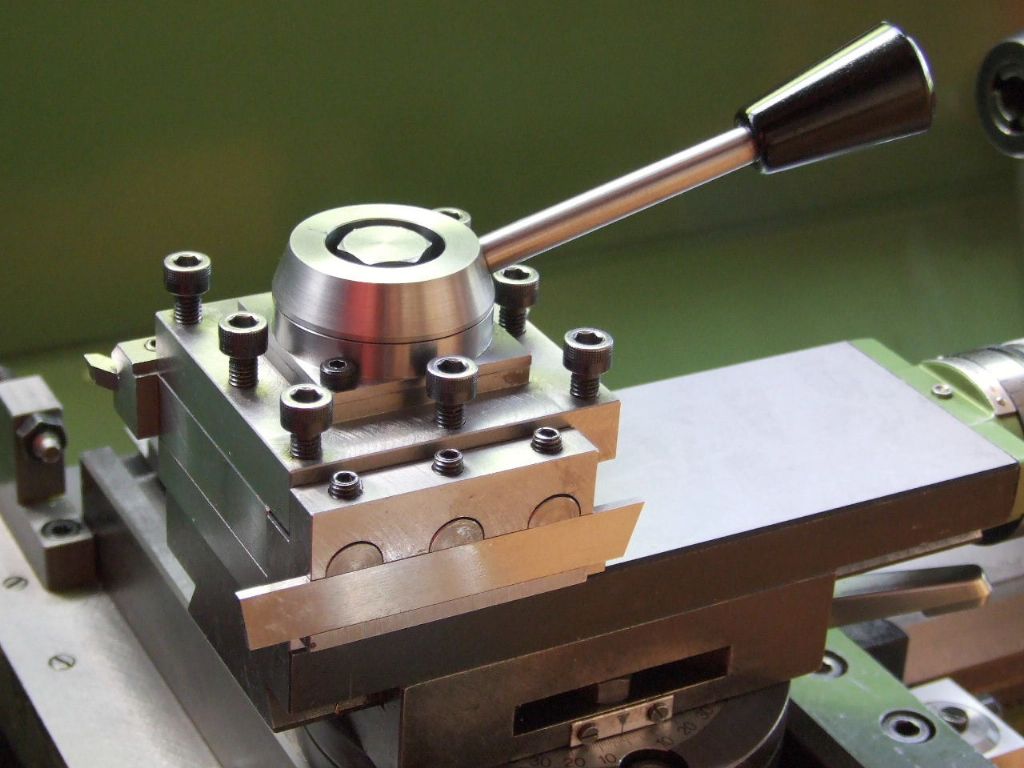

This is the blade holder I made for my Emco Maximat Super 11 lathe. This was the second blade used in 40+ years. The blade is 13 x 2 mm section, it has a dovetail section and is only ground on the front at 10 degrees.

The section of the blade means the swarf is turned on its side as it leaves the cut and it never caused a jam. I now use an 8 x 1,5 mm on my Emco compact 5, with the same style holder. Parting off is carried out with the carriage locked and at normal turning speeds.

I hope these notes help,

Regards

Gray,

Hi Gray, I hope you are well? I'm slightly puzzled, I understand the 10 degrees front rake but what about the top of the parting blade, is its face parallel with the lathe bed but no back rake angle?

Tony

Edited By Tony Pratt 1 on 07/07/2022 15:21:43

Hi Tony,

I hope all is well with you?

Not so good this end, more importantly as of the this morning Jean's health, and in recent months mine, are both taking a nose dive.

Regards

Gray,

Generally,

My observations on parting tools might not suit everyone's view point, but they have worked for me and have never given me any breakages or jams.

The Top edge of the parting tool blade is left with the ground dovetail face, and it is parallel to the plane of the bed surface. The angle of the dovetail face has two functions in the cutting action. The most important is, as the edge is sloping it turns the chip immediately it leaves the cutting edge and puts the chip on its side. Thus the swarf is narrower than the cut and cannot jam up.

The second advantage is that even with the parting blade ground square to the lathe centre-line it still has a pip-less parting action. As the tool is in effect producing a very shallow cone. As the cutting edge is really a product of the dovetail angle and the ground square edge.

A lot of people grind the top face flat, or with a slight top rake. This not only looses the above advantages but it also is reducing the width of the blade due to its in-built tapered section. It also restricts how deep the blade can penetrate the work. As the unground blade above the new ground top face is now wider than the cutting edge. It might not be much, but it is enough to give you a bad day.

The Front rake angle if it is too sharp, allows the blade to penetrate the work very easily. This in my view is what causes the dig-in, as there is no, or very little resistance felt on the feed handle. This results in too big a cut and a jam, dig-in, or breakage. If a moment is taken to think about it. A true vertical face would not cut, and by not cutting it cannot dig in. As the Front rake is increased the tool is allowed to penetrate the work, depending on how much this increase is, equates to how easily the tool can be fed into the work. Hence my opening sentence here. Some resistance to the cutting tool is a good thing in my book.

As I said these are my rationale, it is based on my experience, and advice given to those apprentices in my charge . Even on the smaller Compact 5 I use now, I still have the same set-up, and have been recently parting off 16 mm bar, (BMS & Silver Steel) at 330 RPM with no problem.

Regards

Gray,

Graham Meek.