Posted by Alex du Pre on 03/01/2023 08:43:08:

Huub, thanks from me also for the video and spreadsheet.

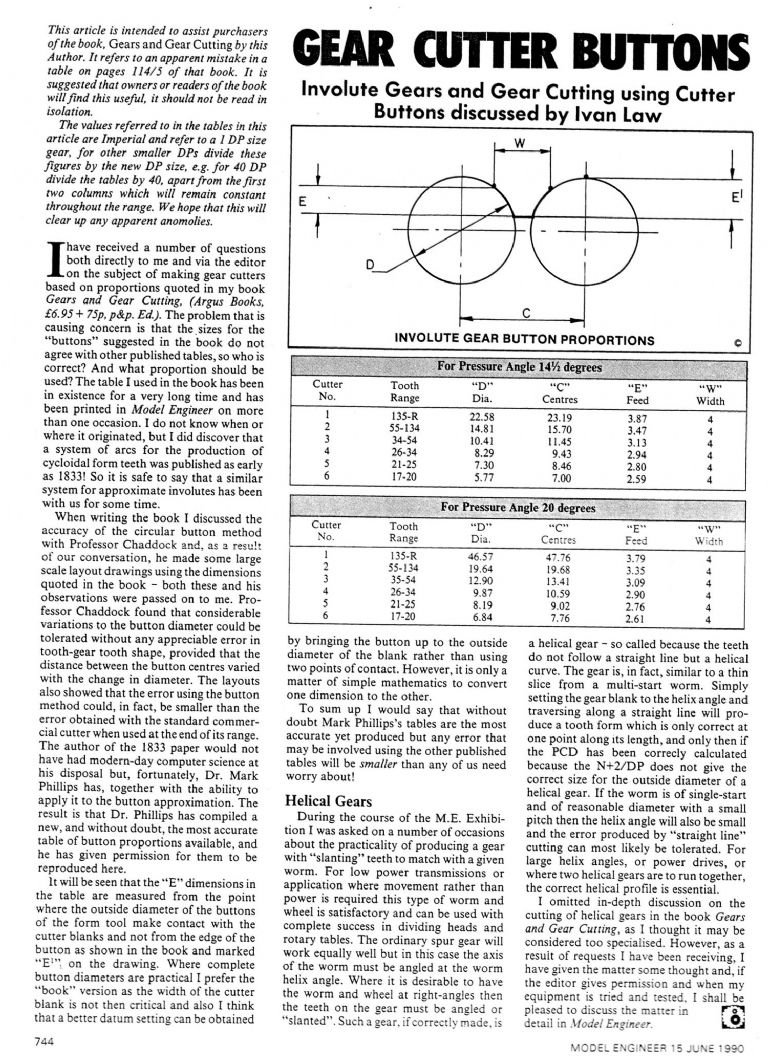

I have a question – are the button tool calc tables on p114 of Ivan Law's book correct (Gears and Gear Cutting book)? Ivan's tables do not agree with the results of Huub's spreadsheet or my own calculations from playing with CAD. My calcs agree with Huub's! Ivan's tables give button diameters/separations about 50% bigger. Ivan's tables also don't appear to match the results I would expect using his figure on p113.

To get from Ivan's figures to the values you want, you have to divide his figs by the diametral pitch of the gear required. If using Module gears rather than DP, 25.4/MOD = the DP value. e.g. 0.75 MOD = 33.87 DP.

I'd be very grateful if anyone can confirm, or otherwise, the accuracy of Ivan's tables!

Thank you!

My book of Ivan Law is the reprinted version of 2013.

On page 107 if have made a note for the bevel gear calculation to use cos not sin

On page 113 if have made a calculation note: Button Diameter = sin (pressure angle) x PDM (Pich Diameter in mm)

The table on page 114 is made for 1 DP gears 20°. Divide the value in the table by de DP of the gear to cut.

According to this table, a T17 20DP 20° gear would need a button diameter of 0.39" and a button separation of 0.435".

According to the spreadsheet, you need a button diameter of 0.207" and a button separation of 0.341"

I can confirm there is a difference in the results of the spreadsheet and the table in the book.

I will check the results using the formula's of MikesWorkShop and will report it later this day.

Greensands.