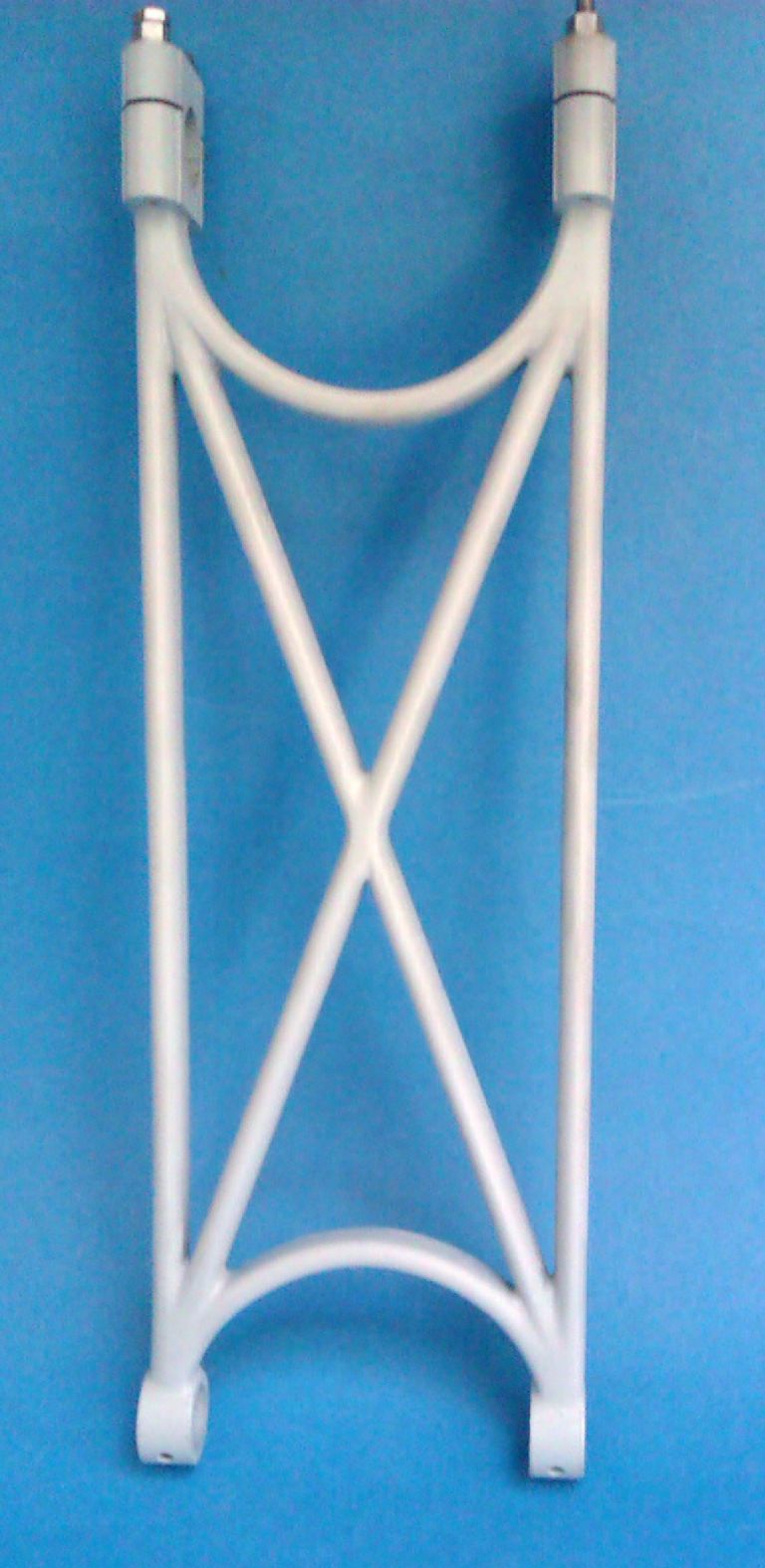

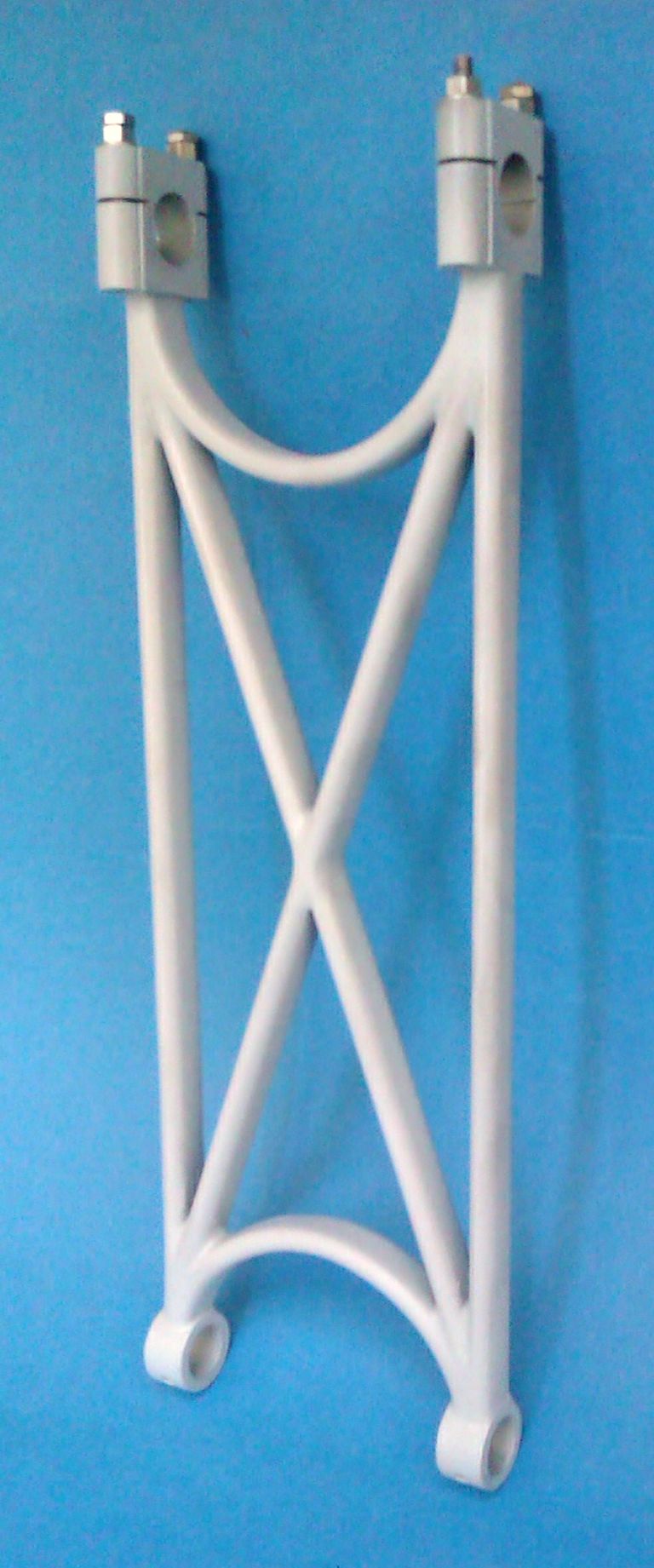

For my next steam project I intend to make Anthony Mount's Easton & Anderson grasshopper beam engine but at double the size, the X braced frame that supports the end of the beam was originally a casting with eliptical section members.

Casting a one off is not really an option so I intend to fabricate and thought I would see if anyone had made eliptical section in the past, the size needs to be about 11/16×9/32 (11x7mm). I need 4No 10" lengths, the half circles at the ends will likely be easier turned as a ring. Material steel or brass.

I have a few ideas as follows

1. Reprofile some tube either by rolling or pressing, 3/8" dia would be about the right starting point.

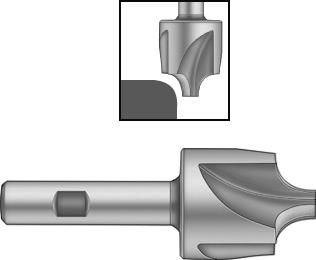

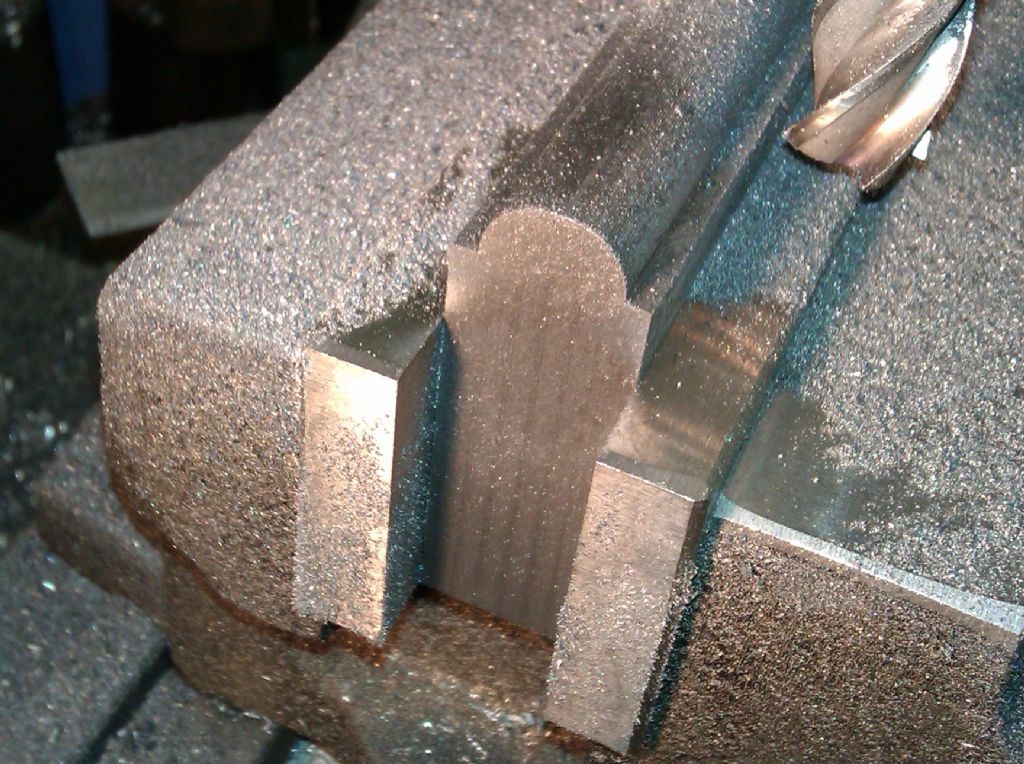

2. Mill using a 1/4" roundover bit to knock the corners off and then blend by hand

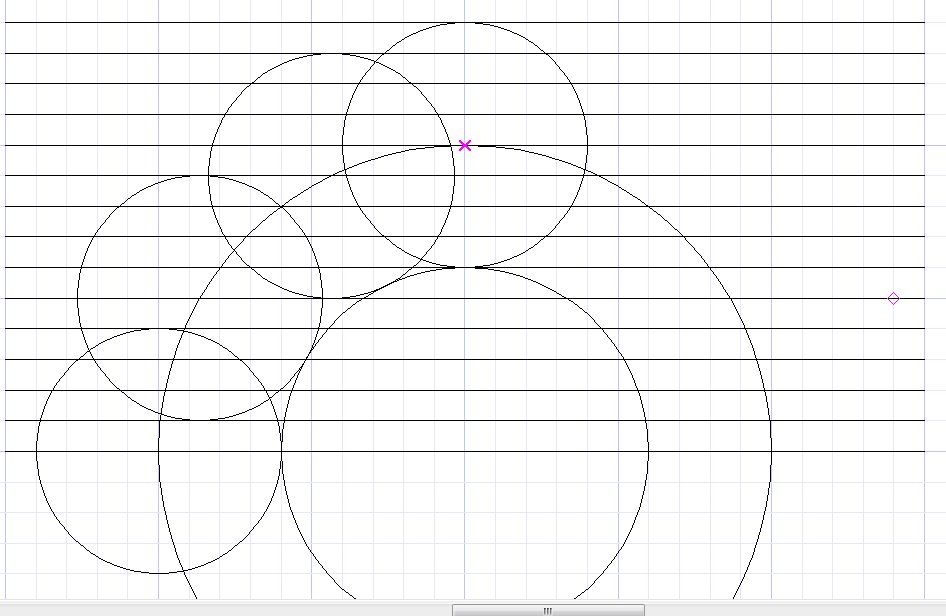

3. Again on the mill but work out co-ordinates to produce the profile in a number of fine steps like the ARC function on a DRO and then final blending by hand

4. Buy it in, I have found a company that does what I want and will get a price on Monday but as they deal with race cars its likely to be an exotic cr-mo alloy and not cheap plus I would prefer to do it myself

So has anyone done something similar and if so how did you go about it?

Thanks, Jason

Edited By JasonB on 02/09/2012 18:39:07

JasonB.

JasonB.