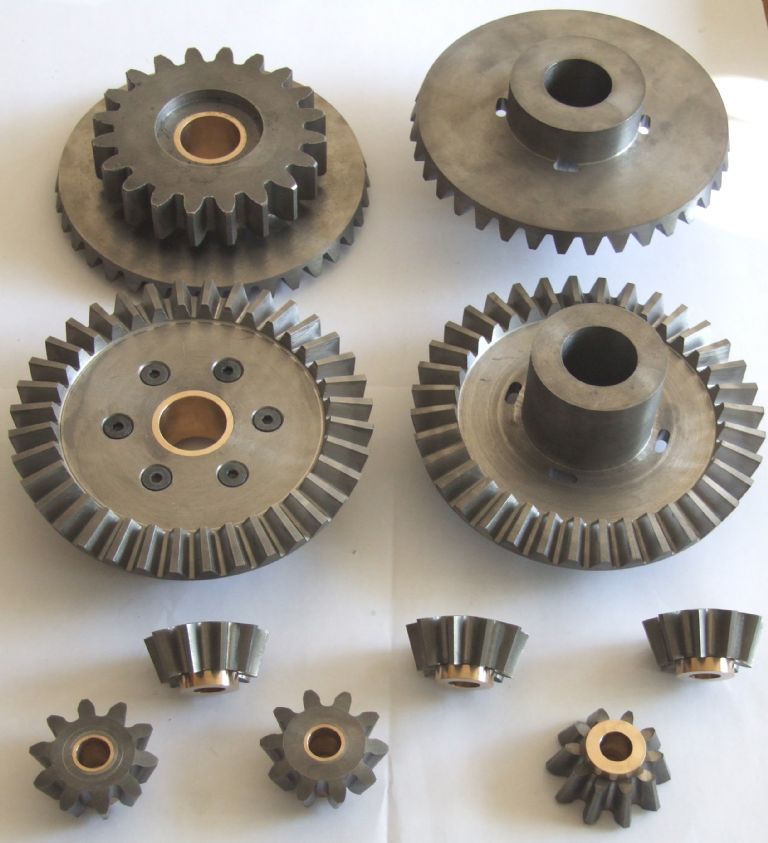

I have previously posted here when I started looking into making bevel gears for my New Shay.

I needed to make a gear of 40T and a pinion of 20T and had the spec. for a set of commercial gears of Mod 12.

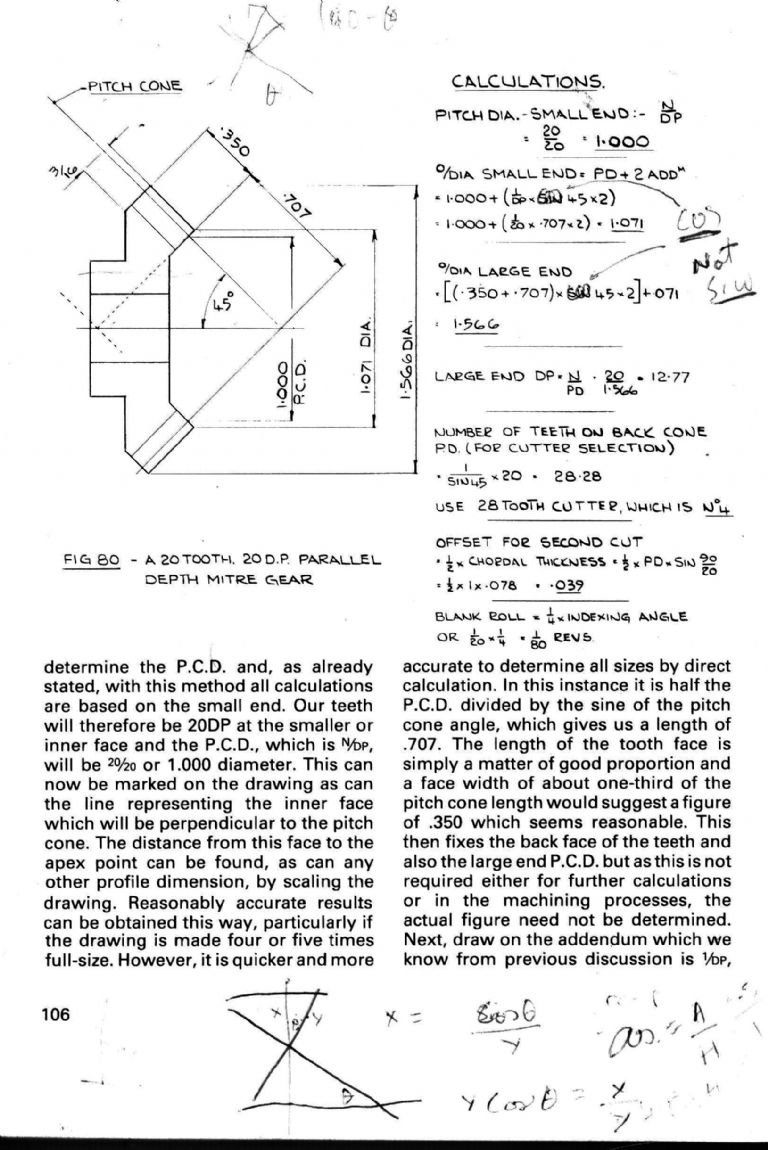

I am making the gears per Ivan Law book on Gears and had heard that there was an error in his directions relating to his use of 1/sin Cone Angle x num teeth in order to find the correct Cutter number and got responses here that the correct formula was 1/COS cone angle x num teeth.

My gear has a cone angle of 63.43 degrees and the pinion is 26.57 degrees.

I then drew a cone with a 63.43 deg angle and a 40 mm pd at the large end bottom and made the drawing 4x in size so it would be easier to work with.

From the drawn cone, I was able to then work back up the cone to the small end and measured a pd of 29.80397040mm for the small end which works out to 29.80397041/40T = Mod .74509926 or .745 which works out to a DP of 34.08941782 or rounding off to 34.1 DP.

I then calculated the estimated tooth number per the formula using COS rather than SIN and got 1/cos 63.43 x 40 =89.42727118 teeth which gives a button cutter of #2. From Laws Table for a 20deg pressure angle, diameter is then 32.15 x .745= 23.95175mm/25.4 = .943 inches.

In figuring the 20 T pinion 1/cos 26.57 x 20 =22.36164558 or 22 teeth, a very small increase.

Have I figured something wrong. Seems strange that I wind up with a cutter of 89 teeth for the gear more than double the size of the original number.

Also, I did cut a set of cutters using a spread sheet I found either here or on another site using Laws book to make parallel bevels and after I finished making the cutters from the spread sheet, I realized that the spread sheet was also based on SIN rather than COS to determine the tooth number for the cutters, so I went back and started again, where I am now.

Sorry to be so long but want to be exact as to what I was doing.

Bob

Robert Blodinger.