Reporting back, I tried all the advice and got a result!

Deep freezing the pipe hardens the plastic and the tap does cut better as a result. Unfortunately the pipe quickly warms up and the advantage lost almost immediately.

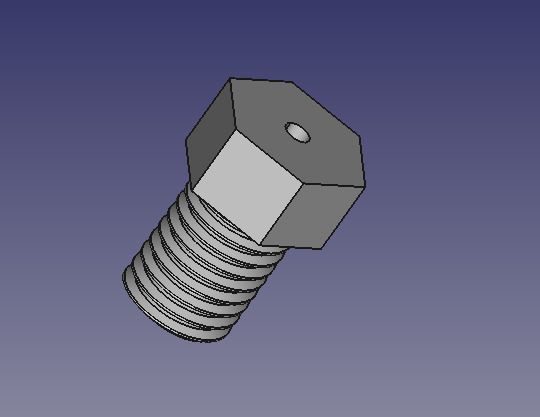

Even with carefully sharp taps (these are essential), I found it is necessary to support the pipe with a collar. If not supported the pipe walls expand away as the tap bites. Even with support the tap still didn't cut the plastic inner cleanly and if made big enough would not enter the pipe directly. I dealt with that problem by using two taps, a small one to create a pilot thread followed by a larger to penetrate the Aluminium. Then to get a good contact, the Aluminium plug has to be made slightly larger again and forced in with a spanner. It helps considerably to remove some of the inner plastic with a Dremel.

The approach works but it is very hard work, prone to bend and doesn't solve the next-stage issue that brass and aluminium are prone to electrolytic corrosion. Also I wasn't satisfied that the Aluminium inner pipe and plug were making a really good contact. Threading left a lot of plastic smeared over the aluminium inner and electrical contact is only made over parts of the thread. As Aluminium oxidises easily I wasn't confident that the joint would last.

Reaming out the inside of the pipe to get a clean electrical contact is possible but it takes ages. I also spoilt a couple of attempts with the Dremel because it removes aluminium faster than plastic when you get to it and the Aluminium barrier is very thin. At this point I decided not to make an expanding plug. I'm certain it would work, but it's more error prone than a screw plug and it would need a permanent collar to stop the flexible pipe creeping off.

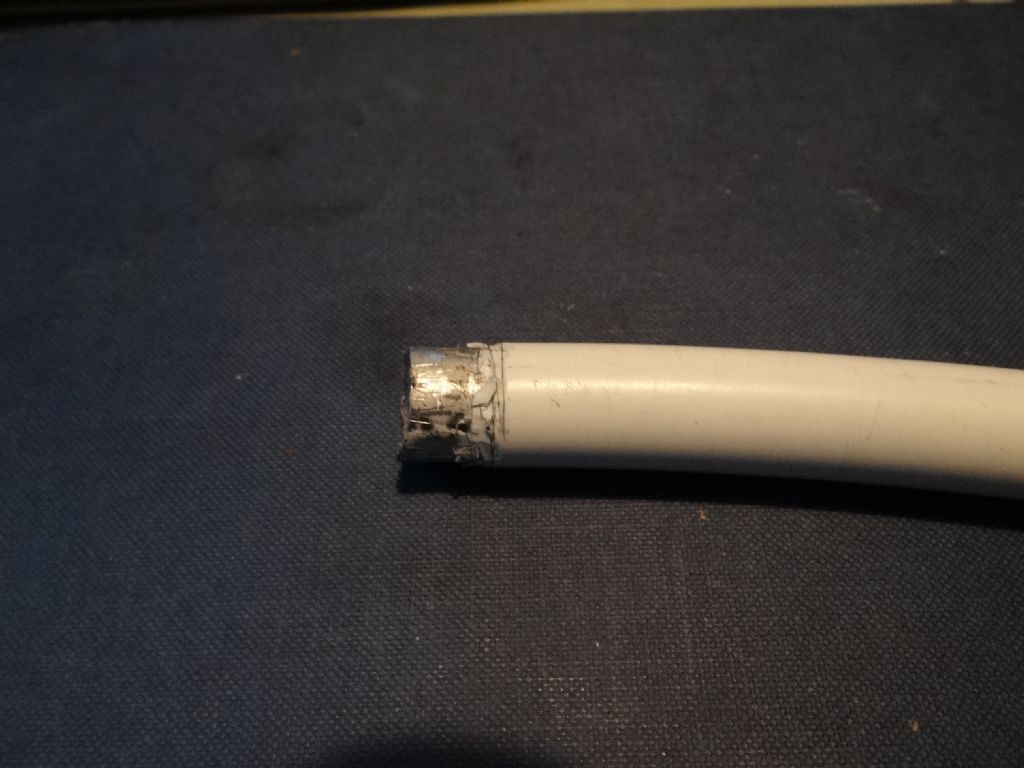

I left Neil's suggestion till last because I don't like soldering Aluminium foil and feared melting the pipe. Not a problem in practice, Neil's method is straightforward. I exposed an area of Aluminium with a sharp Stanley Knife, cleaned it to bright silver by scraping with the knife edge, applied 3-in-1 oil to stop oxidation, and tinned with a 140W solder gun. I used old-fashioned 60:40 lead electronic solder rather than the modern tin variety. Once the Aluminium is tinned it is easy to solder copper wire to the pipe, job done!

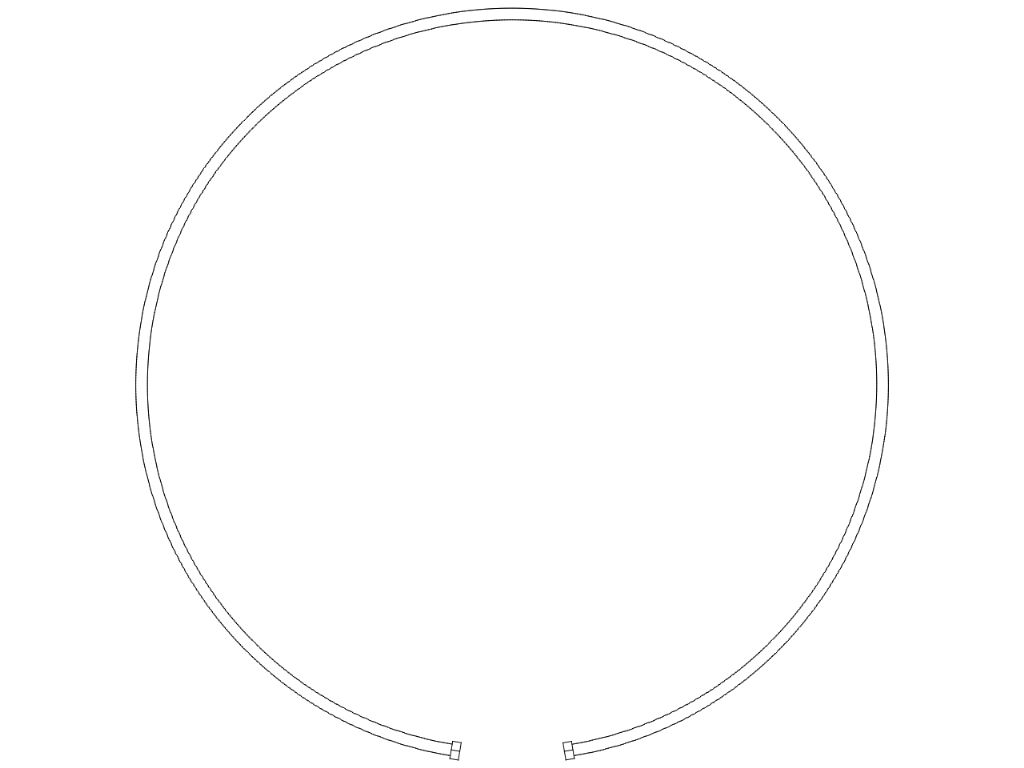

No melting to speak of and the brown mess is only cooked 3 in 1 that cleans off. The pipe bends nicely into a perfect loop.

Unfortunately nothing is ever easy! The 16mm plastic pipe doesn't fit my standard water pipe clips and the 2.4m plank I was going to use as the support turns out to be only 2m long – too short to finish the antenna today.

Lesson learned : simple solutions are usually the best!

Cheers,

Dave

Neil Wyatt.

Neil Wyatt.