Making a screwcutting tap

Making a screwcutting tap

Home › Forums › Workshop Techniques › Making a screwcutting tap

- This topic has 27 replies, 6 voices, and was last updated 26 February 2010 at 23:08 by

Ramon Wilson.

Ramon Wilson.

-

AuthorPosts

-

19 February 2010 at 21:47 #48877

Peter G. Shaw

Participant@peterg-shaw75338Hi folks,

A recent project with my grandson resulted in an attempt to make a UNF 3/8 24tpi tap out of silver steel. Lots of things went wrong but we did eventually manage to cut a thread in a piece of aluminium. This is what we did, along with what we know we did wrong, but I’d like to ask, for the future that is, for any other thoughts.I should point out that one of the reasons for this project was to let the grandson do as much as possible, and to see the rest.

First we took a piece of half-inch silver steel and turned it down to 3/8ths. Unfortunately the only way that we seem to be able to get a smooth, and hence accurately measureable, surface is to rough turn first, then finish turn using high speed and slowest possible manual feed. So of course, the finished surface ended up slightly less than it should have been, and a repeat attempt the same. As it happens, the device that was intended to screw in was itself slightly less, so we continued.

Next we screwcut. In retrospect we should have produced the taper first, so that was yet another mistake. Anyway, I’ve never had much luck with trying to calculate depths of cut etc for screwcutting and so had to resort to using a nut as a test piece. So this is what we did, and produced a thread.

At this point we tapered the job. That was ok, we used 8° included as per Tubal Cain’s instructions.

Then we tried to create a cutting edge using a minidrill with a grinding disc in the chuck. We had looked at other similar sized taps and realized that we needed to produce an undercut under the cutting edge and so we tried to set the minidrill appropriately. We weren’t particularly successful and finished up using a file to try to improve matters. Thoughts on how to do this would be most appreciated. Also on how to produce, say, three cutting edges.

Having got this far we then hardened it. Ok we didn’t bother with the one hour per inch as per Tubal Cain and others, but neverthe less got it very hot and then quickly dunked it in cold water. This was followed by tempering to light straw, although here again I suspect we may have heated it too quick and possibly had some of it nearer brown.

We tried it out on a piece of aluminium, slowly increasing the drill size until we could get it to cut, which it did after a fashion. After cleaning up, we found that the original device it was meant for could actually be screwed in, albeit tightly, so in that respect it was more or less successful.

Grandson, by the way, was absolutely delighted with the result, even though it wasn’t perfect. To him, it was the act of screwcutting in the lathe and then hardening and tempering the silver steel, none of which he has ever seen before.

So, thoughts please.

Peter G. Shaw

19 February 2010 at 21:47 #15456Peter G. Shaw

Participant@peterg-shaw7533819 February 2010 at 21:50 #48879Peter G. Shaw

Participant@peterg-shaw75338Oh dear, I’ve managed to enter it twice. Can I suggest that any answeres should appear on this particular thread. My apologies for this cock-up.Peter G. Shaw19 February 2010 at 23:10 #48885mgj

Participant@mgjPeter I have just done a 1/4 x 16 square castle thread tap, and that worked fine in bronze.One ought to form relieve on the trailing edge of the cutting face. Sadly I don’t have a form relieving tool, though the Quorn will do it. Thats a tragedy I just have to live with.So, I just turned the thread to size (very slightly oversize) to give clearance when I cut the real thread to dimension. In silver steel. Then I put the taper on, and then I milled the cutting faces.I set the milling cutter to cut dead to centre, looking down from above and depth of cut was to bottom of thread. I cut 4 cutting faces. 3 would have been better . So I had 4 cutting faces at zero rake.Hardened to bright red, didn’t temper, because the cutting edges temper soft and the centre stays hard (I don’t have a sandbox)Then I tapped the bronze nut. Bit of a rachet action, 1/8 turn fwd and click back (no form relief!) and slow progress but it did thread the bronze fine and to hte size required.. and the “bolt” of the brake mechanism which had been cut to size fitted fine, so I had no fiddling. Lots of RTD!!So the only difference is the way the edges were put on – mine was cribbed from GHT dividing and graduating – how to make a spotfacer.Without proper form relief, and proper grinding these taps will always be imperfect and more suited to single object runs, but in general does that matter to the modeller.Jason did a similar exercise for his TE, so it would be interesting to hear how he did.

Edited By meyrick griffith-jones on 19/02/2010 23:15:30

19 February 2010 at 23:13 #48887mgj

Participant@mgjThe way I find to get a nice finish on SS is to use a round nose carbide tool – .8mm radius. Lots of coolant, fairly fine finish cut at 600 RPM and .005″ per rev feed. diameter – dunno. I cut everything at 600 RPM.- more or lessIts the coolant which is the important bit.3 or many cutting edges – dividing head in simple indexing mode. Or any equivalent indexing set up.Edited By meyrick griffith-jones on 19/02/2010 23:18:30

20 February 2010 at 12:13 #48903Peter G. Shaw

Participant@peterg-shaw75338Hi Meyrick & Ramon,Reading both threads – I wish there was some way of removing a duplicate, moderators please note – I note that you did not bother tempering, and screwcut slightly large. Screwcutting slightly large was something I had thought about but have no idea how much larger. May I ask how much larger? I take the point about the cutting edges tempering softer.The tool-to-be was left mounted in the chuck for all operations. My mandrel does have 12 equally spaced holes around it so indexing to three or four is dead easy and my original intentios was to do three, however the grinding operation was not exactly good, so we stuck with one. The minidrill grinder was mounted on the vertical slide so we got the three axes of movement. We angled the grinder and mounted it on centre expecting to produce an undercut – then we realised that this wouldn’t work, hence the file.It did occur to me that perhaps using a milling cutter might have been better, but I haven’t yet got suitable facilities.We were using carbide tools for the initial turning, not round nose, but one with a sharpish point with the point just taken off. Even so, I find the damn things chip far too easily. (When I finally grind these things down to a minimum size I will replace with either HSS, or possibly even carbon steel.) The actual thread cutting was done with the very first tool I ever made – ¼” square carbon steel – made about 20 years ago and which does seem to work quite well although we noticed that it does now need fettling.We did not use any coolant for the initial turning, but we did use some when screwcutting, which was done using a mandrel handle – 125rpm is a tad too fast for me when screwcutting about 1″!Using oil to cool. Will ordinary clean engine oil do? Sand for tempering. Ordinary builders sand (sharp sand)?Many thanks so far.Peter G. Shawps. As you say, making a cutting tool, and then using it is extremely satisfying. I have made a three-lobe countersink out of silver steel, and although not perfect it certainly works. And best of all, the grandson is delighted and is taking it to show his engineering teacher at school.

20 February 2010 at 13:25 #48909mgj

Participant@mgjYou want to be careful using oil to cool. Especially as a model engineer who doesn’t have access to proper temperature controlled facilities. Metallurgically you are trying to get the thing to through harden so you want to “freeze” it ASP. Which oil doesn’t always do – nor are we relying on a carbon take up from the oil to augment surface carbon. Having said that, mostly its fine, if smelly and unpleasant.THE stuff for quenching is brine. Common or garden brine and you should insert the quenchee vertically. (don’t ask for a strength – just brine!!!! On the basis that its better to be approximately right than exactly wrong))Oils fine for carburising as a finish, and heating in oil is good way of getting up to tempering temps and holding it there – or one way of doing it.Which oil – most people would use old sump oil, but its smellier and dirtier than fresh. also it will contain quite a bit of fuel from blowby, especially from a diesel. You pays your money and takes your choice, but fresh or old don’t matter a damn.Sand – see post above. Metallurgically all you are trying to do is heat evenly. Yyou could use rice, talcum powder, anything that just hold the heat and transfers it into the object uniformly. You can of course temper quite happily in a domestic oven. Just laid on a tray. Its just easier to use a flame, watch the colours and throw it in the brine just before it gets to your colour. By the time, on a small object, it hits the coolant, it will have gone right. Again, having said that, doing the 10 secs per inch is the proper way to do it, but on thin sections there isn’t a problem. (How thin is thin – buggered if I know, just try. If it hasn’t worked press the reset button by reheating to red and do it properly!)Countersinks – if you look at GHTs book he offers advice on countersinks – and recommends, effectively a pointed D bit. He is dead right, they cut beautifully and NEVER chatter -and a touch easier than 3 lobes to make!Screwcutting larger – this was a square thread – bit like an Acme, 1/4 x 16, so each thread was .032 wide. So I gave it .002 on dia and .034 on the upstanding threads which were going to be the spaces of course. Its only a TE brake system so frankly it only needs to fit where it touches, but this screwed in fine without excessive clearance. On a tap – there will be tables to give you precise dias, but I’m not sure they are hugely relevant because we are only likely to make a tap for a one off – a standard tap for a standard thread, the individual is unlikely to make.In this case the tap was going to cut bronze so nil rake suited. The easy way is to use a ball nose milling cutter, and plunge from above, and traverse along the tap. When you look end on you’ll see the hook in the cutting edge which is the lower edge – ie make sure you get the rotation direction right, or you’ll end up making a very sharp left handed tap with a right hand thread – which is quaint, but not useful!You should get the hang of these infeeds and screwcutting angles, because its nothing to be frightened of. You know your ratios, or select on the gearbox, support at both ends, sharp tool, take shallow cuts (.005″) and munch metal. Things can go wrong, and jobs can spring and people can get crossed up on the thread dial indicator. But in most cases, when you have infed the right amount, the right amount comes off and its going to fit. Once you have done it a bit, you get the confidence, and success ceases to be a miracle.Do you have the Model Engineers Handbook?. It lists all of this in very easy form. Ian Bradleys “The Myford Manual” has a lot of excellent “how to” advice. It is Myford specific, but once you have a process sussed, doing it on a different lathe don’t take the brains of an archbishop.Cardide tips – sorry I assumed you were using an indexable one. I’ve never had much luck with the brazed on ones. Bloody impossible to sharpen properly freehand. Have a birthday and get a tangential one!!! I agree with Ramon about cutting Silver steel with a lot of rake with HSS, simply because my tools do have a lot (suits leaded freecutting mild). Having said that, again indexable tips with nowhere near as much rake (nearly zero) do cut SS very well, and produce almost a mirror finish, as long as you use the right nose radius.Edited By meyrick griffith-jones on 20/02/2010 13:38:42

Edited By meyrick griffith-jones on 20/02/2010 13:50:42

20 February 2010 at 14:09 #48912Circlip

Participant@circlipMeyrick, you can add all the Martensitic or Austenitic or Spheroidal graphite or altropies you like, but unless one has the ability to ACCURATELY measure the temperatures, Dull red or Bright red or Cherry red??? are the easy ones for us general dobbins to use. As far as tempering is concerned, I keep throwing this one in, a VERY efficient source of a tempering “Oven” sits in most kitchens and providing that the bits are CHEMICALLY clean and no trace of oil or other detritus. You can set the thermostat on the domestic cooking oven and dangle the bits on wires from the racks and WATCH them go the right colour.Sundays works best in our household as the chamber is already up to speed (Or just below it) after the luch is prepared.Did all the theory bit in the lab where I worked when an apprentice Meyrick and had the crazy paving diagram stuffed under me nose, but I don’t have access to the salt baths, Lead baths tempering furnaces OR the measuring and inspection tackle to check it with anymore.Regards Ian.20 February 2010 at 15:01 #48917 Ramon WilsonParticipant@ramonwilson3Hi Peter,As you may have gathered Meyrick and I have have totally differing views on the use of carbide tooling. I’m not advocating their non use just that in my experience of using both, both at home and in a works envirionment, there are times when HSS is much better to obtain a finish particularly to a fine dimension. Carbide to work best has to run at a much higher speed than HSS and given the average kit that the home user has it is probably overkill for most of the time – you only have to see a screw cutting tip being used in the correct fashion on an auto or NC machine to know that you can never attain this at home ‘on the Myford’. The use of carbide at it’s outset was, just as HSS over carbon, to increase speed and feed and more importantly production and thereby income. Fortunately these attributes are not normally at the forefront of the home engineers agenda.Carbides are very brittle and, as you appear to have found out prone to chipping, – just have one set a little below centre height and run it past center. They do do a good job at home on the right application but for myself they don’t feature at all on any finishing operationYou appear to have the neccessary kit to improve upon our first attemt. Simple dividing and the use of something that can act as a toolpost milling spindle. If you look at the tap from the front toward the chuck then the cutting face of the cutter (assuming for instance a ball nose end mill) if in the vertical (12o’clock) position needs to be slightly over centre (toward the right as you look at the chuck) to give a positive rake to the teeth. Only a small amount is required, too much and the diameter will be reduced.Screwcutting is best done as slow as possible – if 125 is the lowest you can get I would think that’s a bit fast especially with the carbon tool you have but it depends on diameter and pitch of course. For those finishing cuts I always use backgear.And so to the heat treatment game!As I’m writing his I have just scrolled up to re read the posts and mine and Meyricks original replies have dissappeared! I see Meyrick has put a new post but this is in answer to the missing one!Theres nothing wrong in Meyricks quote on the technical side , he has explained it very well, but he is wrong on the initial heating. You can over do it – too hot and the metal will attain a crystalisation that tempering will not improve and it will be weak and brittle.If I may digress a little – several years ago I joined a company to work on multi stage progession tooling. The facilities (other than grinding) for making anything were nothing short of absymal. However things improved and new kit was bought and a new ‘machine shop’ was formed for which I was responsible. One of the tasks that was taken on was the increase of heat treatment of parts for some of the tooling. It was a rapid learning curve for me and over the next twelve or so years the amount of heat treatment and grinding rapidly grew and became virtually a daily occurance. The steels involved varied from basic silver steel, gauge plate, Arne B01(the most frequent) Carrs, KE and several swedish steels including Sverker 3 and 21. All the heat treatment was carried out using two electric furnaces and a separate tempering oven and all was done carefully following the manufacturers heat treat instructionsThe thing that struck me most the first time gauge plate and silver steel parts came out of the furnace was just how dull they were – nowhere near the ‘red’ normally considered to be the requirement. After quenching the parts were checked for hardness and the ‘rockwell’ was spot on. It was obvious that the steel did not need to be heated as much as is normally considered when flame hardening! Since that point in time something that I have endeavoured to emulate when making parts at home. Taking the colour too high in order to increase the hardness will not gain much before the make up of the steel is affected.Tempering was also a big eye opener and serves to show how the home user is merely doing his best! To be carried out correctly Arne B01 (virtually the same as gauge plate) and most other steels required a two hour soak at the correct temperature – twice! Meyrick is quite correct here- the temperature is important to do the job properly but this should serve to show this is something most of us at home cannot carry out.To get it into perspective I think it’s fair to say that for most of us we need to make and heat treat a small tool that will work without breaking just to get a job done. It hasn’t got to perform at optimum conditions to produce an income so to me the technicalities are less important than the knowledge of how to do it in the home workshop.We all know that for years the only guide the home user has had for a tempering guide is to use the colour as it oxidises. By using a sand tray the heat is slowly built up in the part and more importantly uniformly around it. It will never be tempered optimumly in this fashion but it’s all we have. Apologies for repeating it but you do have more control over the situation than playing a soft flame onto the part and watching the colour rise up it.Soft sand – the softer the better- well dried out before putting anything in it is all that’s needed Peter. A tobacco tin is more than enough for most small tools. By the way do one tool at a time. It’s a20 February 2010 at 15:07 #48918

Ramon WilsonParticipant@ramonwilson3Hi Peter,As you may have gathered Meyrick and I have have totally differing views on the use of carbide tooling. I’m not advocating their non use just that in my experience of using both, both at home and in a works envirionment, there are times when HSS is much better to obtain a finish particularly to a fine dimension. Carbide to work best has to run at a much higher speed than HSS and given the average kit that the home user has it is probably overkill for most of the time – you only have to see a screw cutting tip being used in the correct fashion on an auto or NC machine to know that you can never attain this at home ‘on the Myford’. The use of carbide at it’s outset was, just as HSS over carbon, to increase speed and feed and more importantly production and thereby income. Fortunately these attributes are not normally at the forefront of the home engineers agenda.Carbides are very brittle and, as you appear to have found out prone to chipping, – just have one set a little below centre height and run it past center. They do do a good job at home on the right application but for myself they don’t feature at all on any finishing operationYou appear to have the neccessary kit to improve upon our first attemt. Simple dividing and the use of something that can act as a toolpost milling spindle. If you look at the tap from the front toward the chuck then the cutting face of the cutter (assuming for instance a ball nose end mill) if in the vertical (12o’clock) position needs to be slightly over centre (toward the right as you look at the chuck) to give a positive rake to the teeth. Only a small amount is required, too much and the diameter will be reduced.Screwcutting is best done as slow as possible – if 125 is the lowest you can get I would think that’s a bit fast especially with the carbon tool you have but it depends on diameter and pitch of course. For those finishing cuts I always use backgear.And so to the heat treatment game!As I’m writing his I have just scrolled up to re read the posts and mine and Meyricks original replies have dissappeared! I see Meyrick has put a new post but this is in answer to the missing one!Theres nothing wrong in Meyricks quote on the technical side , he has explained it very well, but he is wrong on the initial heating. You can over do it – too hot and the metal will attain a crystalisation that tempering will not improve and it will be weak and brittle.If I may digress a little – several years ago I joined a company to work on multi stage progession tooling. The facilities (other than grinding) for making anything were nothing short of absymal. However things improved and new kit was bought and a new ‘machine shop’ was formed for which I was responsible. One of the tasks that was taken on was the increase of heat treatment of parts for some of the tooling. It was a rapid learning curve for me and over the next twelve or so years the amount of heat treatment and grinding rapidly grew and became virtually a daily occurance. The steels involved varied from basic silver steel, gauge plate, Arne B01(the most frequent) Carrs, KE and several swedish steels including Sverker 3 and 21. All the heat treatment was carried out using two electric furnaces and a separate tempering oven and all was done carefully following the manufacturers heat treat instructionsThe thing that struck me most the first time gauge plate and silver steel parts came out of the furnace was just how dull they were – nowhere near the ‘red’ normally considered to be the requirement. After quenching the parts were checked for hardness and the ‘rockwell’ was spot on. It was obvious that the steel did not need to be heated as much as is normally considered when flame hardening! Since that point in time something that I have endeavoured to emulate when making parts at home. Taking the colour too high in order to increase the hardness will not gain much before the make up of the steel is affected.Tempering was also a big eye opener and serves to show how the home user is merely doing his best! To be carried out correctly Arne B01 (virtually the same as gauge plate) and most other steels required a two hour soak at the correct temperature – twice! Meyrick is quite correct here- the temperature is important to do the job properly but this should serve to show this is something most of us at home cannot carry out.To get it into perspective I think it’s fair to say that for most of us we need to make and heat treat a small tool that will work without breaking just to get a job done. It hasn’t got to perform at optimum conditions to produce an income so to me the technicalities are less important than the knowledge of how to do it in the home workshop.We all know that for years the only guide the home user has had for a tempering guide is to use the colour as it oxidises. By using a sand tray the heat is slowly built up in the part and more importantly uniformly around it. It will never be tempered optimumly in this fashion but it’s all we have. Apologies for repeating it but you do have more control over the situation than playing a soft flame onto the part and watching the colour rise up it.Soft sand – the softer the better- well dried out before putting anything in it is all that’s needed Peter. A tobacco tin is more than enough for most small tools. By the way do one tool at a time. It’s a20 February 2010 at 15:07 #48918 Ramon WilsonParticipant@ramonwilson3It’s done it again!part two ——-It’s amazing how quickly the second part changes colour from the part you have just taken out to quench!The quenching oil we used was ‘Shell’ whale oil. You can use car oil though it is best to get old used stuff. It will work. However it does have volatile components so be ready for it to flash into smoky flame. It is what I use at home.The silver steel parts when first done (at work) were quenched in water. However these parts had a hex broached into them and many cracked from the points of the hex when in use. All subsequent batches were done in oil – problem solved!Hope this helps – this is not to take anything from Meyricks excellent techical advice and descriptions he’s much better at that than me – I’m just more the practical side of things.Regards – Ramon

Ramon WilsonParticipant@ramonwilson3It’s done it again!part two ——-It’s amazing how quickly the second part changes colour from the part you have just taken out to quench!The quenching oil we used was ‘Shell’ whale oil. You can use car oil though it is best to get old used stuff. It will work. However it does have volatile components so be ready for it to flash into smoky flame. It is what I use at home.The silver steel parts when first done (at work) were quenched in water. However these parts had a hex broached into them and many cracked from the points of the hex when in use. All subsequent batches were done in oil – problem solved!Hope this helps – this is not to take anything from Meyricks excellent techical advice and descriptions he’s much better at that than me – I’m just more the practical side of things.Regards – RamonEdited By Ramon Wilson on 20/02/2010 15:09:00

20 February 2010 at 15:27 #48922mgj

Participant@mgjSorry Ramon – you are suggesting that if I heat a steel up to and beyond the transformation temperature, that I won’t be able to temper it subsequently?What exactly do we think happens when the stuff is made and it starts from molten? That it will never temper?You may have to normalise, (depending on the alloy) and take it back up, and hold but these are from temperatures well beyond what a model engineer will achieve with the normal propane torch, even by accident. in general terms all that happens is that you put more energy into the thing and the crystalline changes occur a bit faster.In Circlips speak, yes you heat to cherry and hold, but if you take it to orange that’s hardly going to harm. Most of the reason for not going beyond the transformation temperature is economic. It costs.Also in Circlip speak, the average oven in the kitchen is a very useful item. Probably the most useful tempering facility we have.And one for Circlip – just as a chippie should know his timber, so an engineer should know his materials. What it does and why.

Edited By meyrick griffith-jones on 20/02/2010 15:28:54

20 February 2010 at 16:24 #48926 Ramon WilsonParticipant@ramonwilson3Hi again,No Meyrick I’m not saying that.I’m saying that if you heat it up much beyond it’s designated requirement you will change the structure of the make up and make it crystaline that subsquent tempering will not change .Again I’m not infering that you will render it totally unusable by slightly overheating just that there simply is no need to get it too hot and if you do, if taken too far it will alter the structure. And as far as small section silver steel and gaugeplate is concerned a propane torch of decent size is more than adequate to do that.If the guy who has not done much is told it doesn’t matter then there is a good chance he may overdo it – a bit late when the tap breaks or the cutting edge disappears. This is about helping others not make those mistakes surely? and why do something that’s not required for a successful outcome.The important thing for me is to carry out the job successfully in the first place and not worry too much about the technicalities. That’s not to say that an understanding of it should be ignored but if someone just wants to make a tool and heat treat it successfully to do a job he doesn’t need to know what’s actually going on to be able to do so.Now guys, I really must get into the workshop.Regards for now – Ramon20 February 2010 at 16:25 #48927

Ramon WilsonParticipant@ramonwilson3Hi again,No Meyrick I’m not saying that.I’m saying that if you heat it up much beyond it’s designated requirement you will change the structure of the make up and make it crystaline that subsquent tempering will not change .Again I’m not infering that you will render it totally unusable by slightly overheating just that there simply is no need to get it too hot and if you do, if taken too far it will alter the structure. And as far as small section silver steel and gaugeplate is concerned a propane torch of decent size is more than adequate to do that.If the guy who has not done much is told it doesn’t matter then there is a good chance he may overdo it – a bit late when the tap breaks or the cutting edge disappears. This is about helping others not make those mistakes surely? and why do something that’s not required for a successful outcome.The important thing for me is to carry out the job successfully in the first place and not worry too much about the technicalities. That’s not to say that an understanding of it should be ignored but if someone just wants to make a tool and heat treat it successfully to do a job he doesn’t need to know what’s actually going on to be able to do so.Now guys, I really must get into the workshop.Regards for now – Ramon20 February 2010 at 16:25 #48927mgj

Participant@mgj I begin to see whats happened – while driving into town to buy some compasses. Boiler cladding.We were talking of steels in concept, and silver steel in particular, or I was.The point is that steel alloys contain microscopic amounts of alloy material. Sometimes the total alloy load is less than a couple of percent. So, very small changes in content can have huge effects on properties and heat treatment required to achieve those properties.Equally, depending on that alloying, and to some extent final function, heat treatment can be very simple, or quite a complex multistage performance. So yes many steels can be screwed up by faulty heat treatment, some tool steels, armour plate, the MARAGING steels to name but 3 – and heat treatment includes welding. .BUT what you CANNOT do is say that because one “tool” steel resents this or that, that all “tool” steels do.So lets keep to the standard high carbon “silver” steel – or well be in all sorts of trouble.Its charming stuff- you heat it and quench – it goes hard. You reheat and temper and its softer and tougher. You heat and quench and its hard again. And so on.Start dragging other materials into it, and you start talking about apples, when everyone else is talking of pears.20 February 2010 at 16:54 #48930

I begin to see whats happened – while driving into town to buy some compasses. Boiler cladding.We were talking of steels in concept, and silver steel in particular, or I was.The point is that steel alloys contain microscopic amounts of alloy material. Sometimes the total alloy load is less than a couple of percent. So, very small changes in content can have huge effects on properties and heat treatment required to achieve those properties.Equally, depending on that alloying, and to some extent final function, heat treatment can be very simple, or quite a complex multistage performance. So yes many steels can be screwed up by faulty heat treatment, some tool steels, armour plate, the MARAGING steels to name but 3 – and heat treatment includes welding. .BUT what you CANNOT do is say that because one “tool” steel resents this or that, that all “tool” steels do.So lets keep to the standard high carbon “silver” steel – or well be in all sorts of trouble.Its charming stuff- you heat it and quench – it goes hard. You reheat and temper and its softer and tougher. You heat and quench and its hard again. And so on.Start dragging other materials into it, and you start talking about apples, when everyone else is talking of pears.20 February 2010 at 16:54 #48930Peter G. Shaw

Participant@peterg-shaw75338Lots of very interesting stuff here. Many thanks gents.Also, a big thankyou to Richmond for locking the other thread. As I said in that thread, it was my fault, and I’m still not sure what I did. Anyway…Ramon, I think the missing posts are in the other thread.Now, an auxiliary question which follows on from what Ramon was saying about colours and overheating. Both the tap, and the countersink showed definite signs of, dare I say, what looked like “inclusions”. These appeared after the initial heating and cooling. Does this suggest that I have overheated the steel?Regards,Peter G. Shaw20 February 2010 at 17:21 #48932 Ramon WilsonParticipant@ramonwilson3If nothing else Meyrick I’m sure we are entertaining the troops.If you care to re read my posts at no time did I infer all steels were the same indeed I made the comment that silver steel (and gauge plate of course) are the most readily available and accessible tool steels to the average model engineer and this was what I was concentrating on. That early experience of heat treating these steels under very controlled circumstances highlighted the most obvious factor – the low level of ‘redness’ when bringing them out of the oven. Remember at the time this was to someone who as an ME had only heat treated at home using the normal means – the difference was strikingSome of our steels were quenched at over a 1000 c – (the Sverkers) coming out quite yellow – some were tempered at much higher temperatures (than SS and gauge plate that is) – of course you can’t compare them all like for like.I come back to it – the average ME with little knowledge of the subject can still successfully heat treat a piece of steel and use it for a cutting tool without ever knowing what’s going on.Call it the “If I do this then I get this” syndrome if you like but of course if one wants to learn all they can about a specific process then that’s entirely down to the individual. You just don’t need to in order to make a tap.Now may I respectfully suggest a two hour cease fire – I need to fettle my crankcase!Regards – RamonPeter,Just read your post. Yes realised about the threads.By inclusions do you mean scale like appearances or pitting. If so then yes you may have oveheated or you held them in the flame too long. There are ways to overcome this – proprietary compounds – coating it with soap etc even wrapping it with stainless foil. Unless you really need the surace finish to be perfect just heat as quickly as you can without overdoing the heat. That may sound a bit cointradictory but don’t hit a small piece with a fierce flame just one sufficient and bring it up evenly – don’t let the heat soak though from one side – get your tongs hot too and be ready to quench it out when up to temp(colour). Don’t drop it in the quench but dip it in quickly but uniformly in a vertical direction – if it goes in on an angle then it will probably distort..

Ramon WilsonParticipant@ramonwilson3If nothing else Meyrick I’m sure we are entertaining the troops.If you care to re read my posts at no time did I infer all steels were the same indeed I made the comment that silver steel (and gauge plate of course) are the most readily available and accessible tool steels to the average model engineer and this was what I was concentrating on. That early experience of heat treating these steels under very controlled circumstances highlighted the most obvious factor – the low level of ‘redness’ when bringing them out of the oven. Remember at the time this was to someone who as an ME had only heat treated at home using the normal means – the difference was strikingSome of our steels were quenched at over a 1000 c – (the Sverkers) coming out quite yellow – some were tempered at much higher temperatures (than SS and gauge plate that is) – of course you can’t compare them all like for like.I come back to it – the average ME with little knowledge of the subject can still successfully heat treat a piece of steel and use it for a cutting tool without ever knowing what’s going on.Call it the “If I do this then I get this” syndrome if you like but of course if one wants to learn all they can about a specific process then that’s entirely down to the individual. You just don’t need to in order to make a tap.Now may I respectfully suggest a two hour cease fire – I need to fettle my crankcase!Regards – RamonPeter,Just read your post. Yes realised about the threads.By inclusions do you mean scale like appearances or pitting. If so then yes you may have oveheated or you held them in the flame too long. There are ways to overcome this – proprietary compounds – coating it with soap etc even wrapping it with stainless foil. Unless you really need the surace finish to be perfect just heat as quickly as you can without overdoing the heat. That may sound a bit cointradictory but don’t hit a small piece with a fierce flame just one sufficient and bring it up evenly – don’t let the heat soak though from one side – get your tongs hot too and be ready to quench it out when up to temp(colour). Don’t drop it in the quench but dip it in quickly but uniformly in a vertical direction – if it goes in on an angle then it will probably distort..Edited By Ramon Wilson on 20/02/2010 17:22:21

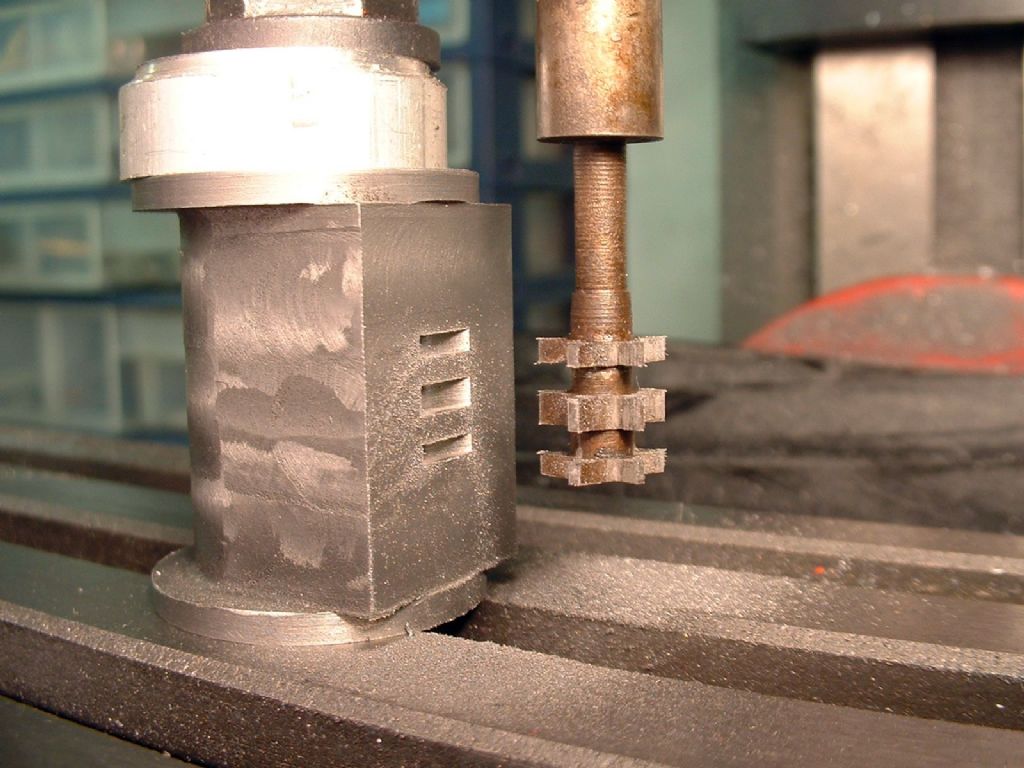

20 February 2010 at 19:07 #48938 Ramon WilsonParticipant@ramonwilson3Timing – it’s all about timing!Just picked up the dremel when guess who? “Don’t start now dear I’m about to start the tea”So on that basis and the old ‘one pic’ etc I rummaged out some tooling and took a few pics. Before you may think otherwise I know that lot’s of you have done very similar and to more extent much better but this is for those who haven’t.So for what they’re worth :This shows tooling tempered by holding in a soft flame and allowing the temper to creep up the tool as you can see most are attempted to quench out a light straw but some have gone past it!.This shows cutters tempered in hot sand. As you can see, on this one the colour is more even overall, the dark areas being as quenched and not cleaned before tempering.I couldn’t find anything with the effect Peter was talking about. This tool was left in its ‘as quenched’ state but looked to have some surface pitting. A quick whizz in the drill with emery shows this not to be except just near the point.These two form tools (to make globe valves) were flame heat treated and tempered at home. (Though they have been ground on a surface grinder it must have been my last place as otherwise the forms would have been ground too!)And finally a tap though this one was done in a furnace and tempered in an oven. It was made to make a bronze leadscrew nut for the mill table and did not have any backing off. It was a devils hind teeth to get through even after screwcutting but it did produce a superb nut!As I say I’m sure there are much better examples out there but if it helps someone then it’s worth posting.I’m reliably informed that tea is on the table!

Ramon WilsonParticipant@ramonwilson3Timing – it’s all about timing!Just picked up the dremel when guess who? “Don’t start now dear I’m about to start the tea”So on that basis and the old ‘one pic’ etc I rummaged out some tooling and took a few pics. Before you may think otherwise I know that lot’s of you have done very similar and to more extent much better but this is for those who haven’t.So for what they’re worth :This shows tooling tempered by holding in a soft flame and allowing the temper to creep up the tool as you can see most are attempted to quench out a light straw but some have gone past it!.This shows cutters tempered in hot sand. As you can see, on this one the colour is more even overall, the dark areas being as quenched and not cleaned before tempering.I couldn’t find anything with the effect Peter was talking about. This tool was left in its ‘as quenched’ state but looked to have some surface pitting. A quick whizz in the drill with emery shows this not to be except just near the point.These two form tools (to make globe valves) were flame heat treated and tempered at home. (Though they have been ground on a surface grinder it must have been my last place as otherwise the forms would have been ground too!)And finally a tap though this one was done in a furnace and tempered in an oven. It was made to make a bronze leadscrew nut for the mill table and did not have any backing off. It was a devils hind teeth to get through even after screwcutting but it did produce a superb nut!As I say I’m sure there are much better examples out there but if it helps someone then it’s worth posting.I’m reliably informed that tea is on the table! Regards – Ramon20 February 2010 at 21:10 #48942

Regards – Ramon20 February 2010 at 21:10 #48942Peter G. Shaw

Participant@peterg-shaw75338Nice pictures Ramon. That’s a lot better than reams of reading as now I can see what others have done and I now have something to aim for instead of blindly aiming in the dark. Many thanks.Now, if I can work out how to do it, I am about to post two pictures of the countersink which show the “inclusions” (for want of a better word). Your thoughts would be most welcome, especially if it’s due to overheating.Hooray, done it! Which just goes to show that one CAN teach an old dog new tricks!Regards,Peter G. ShawOk edit no.1 Apologies for the quality of the photos. The camera is a Canon Powershot A610 used in Auto mode, Macro, and flash turned off. And handheld! Photographer I ain’t.Edited By Peter G. Shaw on 20/02/2010 21:12:45

20 February 2010 at 21:38 #48945 Ramon WilsonParticipant@ramonwilson3Hi PeterYes I think that would be fair to say slightly on the rare side of well over done! But it works – which is the main thing.Probably a little high temperature but more likely under the heat for too long. Meyrick can probably tell us the technical reasons – in laymans however by over soaking you bring the carbon to the surface and it oxidises.Photos are fine. Mine are all hand held – just a 2mp Nikon.Glad to be of helpHave funRegards – Ramon22 February 2010 at 16:37 #49017

Ramon WilsonParticipant@ramonwilson3Hi PeterYes I think that would be fair to say slightly on the rare side of well over done! But it works – which is the main thing.Probably a little high temperature but more likely under the heat for too long. Meyrick can probably tell us the technical reasons – in laymans however by over soaking you bring the carbon to the surface and it oxidises.Photos are fine. Mine are all hand held – just a 2mp Nikon.Glad to be of helpHave funRegards – Ramon22 February 2010 at 16:37 #49017Peter G. Shaw

Participant@peterg-shaw75338Hi Ramon,Many thanks.Now, I WAS going to buy a proper UNF tap, but now I’ve decided to get some more silver steel instead and have another go. Watch this space….Regards,Peter22 February 2010 at 17:28 #49021Michael Cox 1

Participant@michaelcox1Hi all,I have made two taps to date. Both are 10 mm diameter 1 mm pitch left hand thread for making nuts for my minilathe leadscrew. Both worked although the first was very hard work to get through the brass nut. Both made from EN3 rod that was threaded then tapered 8 degrees. The flutes were milled with the mill slightly over centre to give a small positive rake. The first was milled to give a threaded land of about 4 mm and the second had a threaded land of only 2 mm. Both were case hardened in charcoal for 1 hour and then quenched. Neither had any relief. The first was really hard work to use but the second was much easier. I ascribe this to two reasons. Firstly, with lesser land there is less friction and secondly the deeper flutes provide better chip clearance.Mike23 February 2010 at 13:07 #49064Peter G. Shaw

Participant@peterg-shaw75338Thanks for that Michael, I’ll bear it in mind.Peter23 February 2010 at 22:01 #49088 Ramon WilsonParticipant@ramonwilson3Hullo Peter, That’s the spirit.Regarding Michaels post above on fluting it appears I lost a bit of text in mine regarding moving the cutter over centre. It reads that ‘too far this will reduce the diameter’. It should read – ‘too far this will reduce the depth of flute relative to the diameter’. I’m sure you’ve already seen that the further you go past centre will of course give a more positive rake and reduce the width of the teeth but the core needs to be as big as you can get away with for safety. (That’s ‘tap breaking in the hole’ safety!) You need to be over just far enough to create that positive rake situationMike’s comment on keeping those thread widths to a minimum is a valid one as is the depth for clearance.The smaller the tap the more important it is to keep as much of the force required applied on the actual cutting! When heat treating don’t forget also that the smaller the cutter the quicker it will heat up and therefore the more important it is not to create a brittle condition.I have never carburised a cutter so can’t comment on the technique but I do know that a local, well revered model maker, sadly now departed, was a big advocate of it. I would imagine it’s main advantage is the more ductile core the only disadvantage being the time it takes to heat treat it. Mikes time of an hour is a long time to keep a flame on it if that is the only means of heating you have. I wonder if that could be reduced considerably and still give enough depth of hardness for the job in hand ie for a one off situation. Any thoughts Mike?Keep us posted of your progress.Regards – Ramon23 February 2010 at 23:22 #49094

Ramon WilsonParticipant@ramonwilson3Hullo Peter, That’s the spirit.Regarding Michaels post above on fluting it appears I lost a bit of text in mine regarding moving the cutter over centre. It reads that ‘too far this will reduce the diameter’. It should read – ‘too far this will reduce the depth of flute relative to the diameter’. I’m sure you’ve already seen that the further you go past centre will of course give a more positive rake and reduce the width of the teeth but the core needs to be as big as you can get away with for safety. (That’s ‘tap breaking in the hole’ safety!) You need to be over just far enough to create that positive rake situationMike’s comment on keeping those thread widths to a minimum is a valid one as is the depth for clearance.The smaller the tap the more important it is to keep as much of the force required applied on the actual cutting! When heat treating don’t forget also that the smaller the cutter the quicker it will heat up and therefore the more important it is not to create a brittle condition.I have never carburised a cutter so can’t comment on the technique but I do know that a local, well revered model maker, sadly now departed, was a big advocate of it. I would imagine it’s main advantage is the more ductile core the only disadvantage being the time it takes to heat treat it. Mikes time of an hour is a long time to keep a flame on it if that is the only means of heating you have. I wonder if that could be reduced considerably and still give enough depth of hardness for the job in hand ie for a one off situation. Any thoughts Mike?Keep us posted of your progress.Regards – Ramon23 February 2010 at 23:22 #49094Michael Cox 1

Participant@michaelcox1Hi Ramon,I have a small furnace that I use for melting aluminium that I use for case hardening. I seal the part in a copper tube with charcoal and heat in the furnace for 1 hour. I think the depth of case is a “few thou”. The advantage of this is the core is soft and not brittle. The tap works fine for brass but I have never tried it in steel. Probably you could get a reasonable case with a commercial case hardening compound in a much shorter time and still have a tool that would last a reasonable time in soft metals.With regard to the threaded land width it seems the smaller the better. This could be achieved, after cutting the flutes,by milling off more of the threaded part at quite a shallow angle so as not to reduce the core width too much. When I make another tap I will try this.One detail I omitted in my earlier post was that I used 4 flutes to make the taps.Mike24 February 2010 at 22:38 #49139Sub Mandrel

Participant@submandrelRegarding tempering small objects in silver steel. If you need then fairly hard, put them in the chip pan on 180-190 degrees. Tubal Cain suggested 160 degrees in the chip pan was fine as long as you avoid interrupted cuts. I would temper a tap more than that though.It can take some explaining before your wife appreciates that a clean piece of metal is no threat to the health of the household or the quality of the food…On the other hand, i’ve found that an ordinary over at gas mark 6 gives a nice dark straw temper. I haven’t had any problems with blungting or chipping from tools hardened these ways – this one was done in the oven, note the even colour:25 February 2010 at 10:09 #49154 Ramon WilsonParticipant@ramonwilson3Hi Mike, thanks for your further up date.I do actually have a small bench top electric furnace given to me sometime ago but have never used it. Mainly because I’m a bit nervous of the rather Heath Robinson electrics! Theres plenty of Casenite too so perhaps I should bite the bullet and get it working though I hate to think what it will do to the electric bill!Do you use yours in the workshop? – Casenite smells quite a bit.Neil, The oven is ideal providing there is domestic appreciation and approval! I guess for some that might not be available! Your tap though has a lovely even temper and shows the benefit of using this way.I used the oven to colour the steel lagging on a double diagonal engine. I was able to use spring steel which was much easier to work than the planished blued steel sold for the purpose. This enabled all the work to be done before ‘colouring’ a nice blue/grey.Regards – Ramon

Ramon WilsonParticipant@ramonwilson3Hi Mike, thanks for your further up date.I do actually have a small bench top electric furnace given to me sometime ago but have never used it. Mainly because I’m a bit nervous of the rather Heath Robinson electrics! Theres plenty of Casenite too so perhaps I should bite the bullet and get it working though I hate to think what it will do to the electric bill!Do you use yours in the workshop? – Casenite smells quite a bit.Neil, The oven is ideal providing there is domestic appreciation and approval! I guess for some that might not be available! Your tap though has a lovely even temper and shows the benefit of using this way.I used the oven to colour the steel lagging on a double diagonal engine. I was able to use spring steel which was much easier to work than the planished blued steel sold for the purpose. This enabled all the work to be done before ‘colouring’ a nice blue/grey.Regards – Ramon -

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Workshop Techniques › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

taper pins

Started by:

Garry Coles

in: General Questions

Garry Coles

in: General Questions

- 8

- 11

-

10 April 2025 at 18:08

John Purdy

John Purdy

-

Motor bearings and more

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 5

- 7

-

10 April 2025 at 18:01

gerry madden

-

Warco 220

Started by:

kg788995 in: Introduce Yourself – New members start here!

- 2

- 2

-

10 April 2025 at 17:39

Nicholas Farr

Nicholas Farr

-

High tensile M6 bolts

Started by:

nevillet in: Materials

- 9

- 15

-

10 April 2025 at 16:44

nevillet

-

Good quality Jewellers screwdrivers.

Started by:

Andrew Tinsley in: Workshop Tools and Tooling

- 9

- 14

-

10 April 2025 at 16:34

Hollowpoint

-

Use horizontal mill as saw for metal?

Started by:

ell81 in: Beginners questions

- 17

- 18

-

10 April 2025 at 13:40

HOWARDT

-

Hello

Started by:

tbm in: Introduce Yourself – New members start here!

- 3

- 4

-

10 April 2025 at 11:53

tbm

-

Steam pressure using thermistor

1

2

Started by:

michael howarth 1 in: General Questions

- 17

- 41

-

10 April 2025 at 10:51

noel shelley

-

Small type Reilang oil gun

Started by:

john fletcher 1 in: General Questions

- 2

- 2

-

10 April 2025 at 10:38

bernard towers

-

Myford 254S Lead screw lever issue

Started by:

alan1b in: Help and Assistance! (Offered or Wanted)

- 3

- 4

-

10 April 2025 at 08:16

alan1b

-

Re-Visiting My Stuart Victoria

Started by:

Steve Withnell in: Work In Progress and completed items

- 2

- 2

-

10 April 2025 at 08:00

Diogenes

-

Potential new society in North Yorkshire

Started by:

cliff almond 1 in: Model engineering club news

- 6

- 8

-

9 April 2025 at 22:49

Nigel Graham 2

-

N Devon Model Engineers, is this the end?

Started by:

Engine Builder in: Model engineering club news

- 10

- 12

-

9 April 2025 at 22:45

Nigel Graham 2

-

Half Scale 1/4HP A J Weed Engine

Started by:

JasonB

in: Stationary engines

JasonB

in: Stationary engines

- 4

- 13

-

9 April 2025 at 16:45

JasonB

JasonB

-

Building Bernard Tekippe’s Precision Regulator

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 3

- 4

-

9 April 2025 at 15:12

Chris Raynerd 2

-

DIY Pendulum Timer – GPS-Synced Beat Analyser

1

2

Started by:

Chris Raynerd 2 in: Clocks and Scientific Instruments

- 7

- 26

-

9 April 2025 at 14:01

Bazyle

Bazyle

-

DC Wasp Rebuild

Started by:

William Chitham in: I/C Engines

- 6

- 11

-

9 April 2025 at 09:40

petetwissell

petetwissell

-

24cc DIESEL ENGINE FROM SOLID

Started by:

dean clarke 2

in: I/C Engines

dean clarke 2

in: I/C Engines

- 9

- 18

-

9 April 2025 at 09:37

petetwissell

petetwissell

-

Autodesk Fusion Discount

Started by:

Alan Wood 4 in: CAD – Technical drawing & design

- 4

- 4

-

9 April 2025 at 09:32

John Hinkley

John Hinkley

-

Measuring increments on boring head

1

2

Started by:

Bill Phinn in: Workshop Techniques

- 16

- 33

-

9 April 2025 at 08:51

JasonB

JasonB

-

Myford Super 7 restoration problem.

Started by:

Bootlegger Blacky

in: Manual machine tools

Bootlegger Blacky

in: Manual machine tools

- 4

- 5

-

8 April 2025 at 20:39

Bootlegger Blacky

Bootlegger Blacky

-

Damp proofing concrete floors

Started by:

Duff Machinist in: General Questions

- 15

- 17

-

8 April 2025 at 15:56

Chris Crew

-

Contact Details for the family of Alan Barnes

Started by:

Neil Wyatt

in: General Questions

Neil Wyatt

in: General Questions

- 1

- 1

-

8 April 2025 at 14:05

Neil Wyatt

Neil Wyatt

-

Myford saddle lock issue

Started by:

Andrew Moyes 1 in: Manual machine tools

- 1

- 1

-

8 April 2025 at 13:16

Andrew Moyes 1

-

New member old lathe

Started by:

t1krt in: Introduce Yourself – New members start here!

- 8

- 17

-

8 April 2025 at 12:36

parovoz

-

taper pins

-