Posted by Chris TickTock on 19/09/2020 19:02:46:

Posted by Michael Gilligan on 19/09/2020 18:47:45:

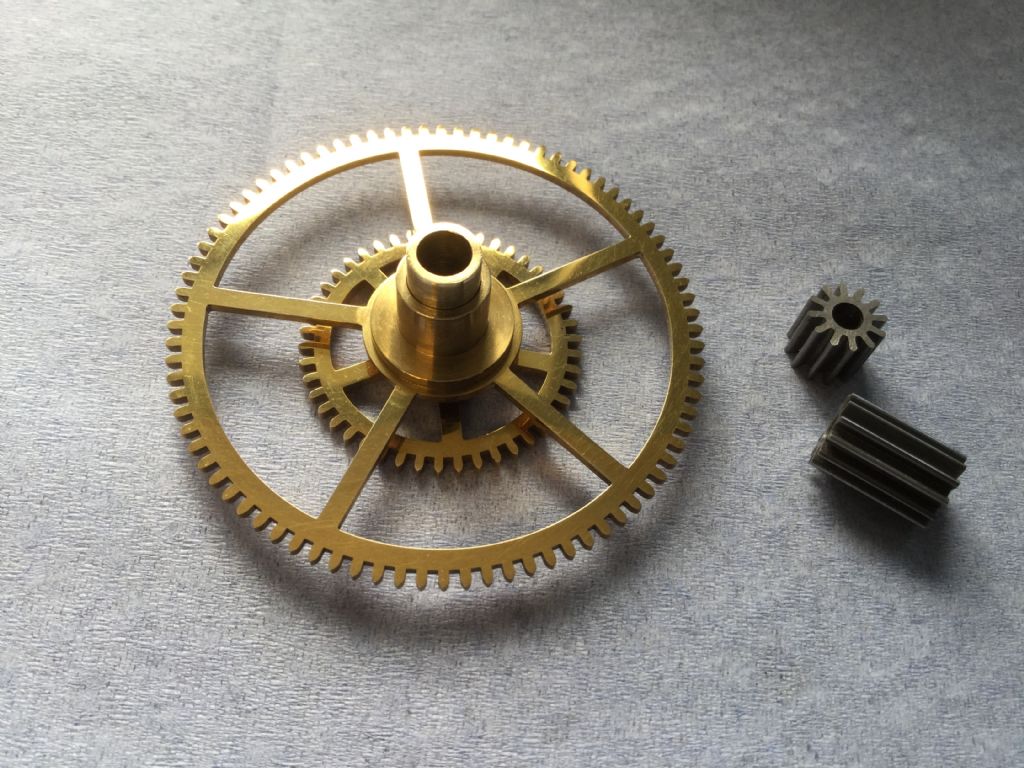

One chap I know has moved to fly-cutting all his wheels and pinions, but he also makes the cutters from HSS.

…

In this case a lot of struggling and plenty of learning.

Chris

Struggling to learn is normal. Some lucky souls are natural machinists, and find everything easy. Not me! Everything has to be practised, and most first attempts are iffy at best.

From a distance what you're doing looks straightforward, but there are a mass of small details to get right. Michael mentions speeds and feeds. Also, there's getting the cutting edge on the blank just right, which is a challenge, followed by heat-treating silver-steel successfully.

My experience of silver-steel is getting the best out of it is a little hit and miss. Judging temperature, how long to hold the metal steady at that temperature, and then plunge cooling without allowing steam to upset the chill are all a bit of a knack. The steel might not be hard enough, or the hardness could be skin deep, or brittle so bits of the edge flake off.

And then there are the cutting properties of properly hardened Silver Steel. It's more akin to Carbon Steel than HSS, meaning it's easy to overheat and less tough. Needs plenty of lubrication and a slower pace than HSS – another learning opportunity.

Some materials are harder to cut than others, yet another detail. EN1A is considerably better than ordinary mild steel, but I would practice on brass first.

It's not that beginners make a mess of everything, rather a few slightly off details combine into erratically disappointing results. Keep trying, and it gradually comes together. Self-teaching is difficult – much easier if an expert shows how it's done, and explains the mistakes you're making. It's a little like learning to ride a bicycle – suddenly things come together and away you go.

I have no problem buying tools and materials to get jobs done, but I enjoy learning too, despite the frustrations!

Dave

Dave S.