Pushing against the end of a 30 mm x 300 mm long workpiece is exerting a lot of levereage on the chuck.

It is probably at or near maximum capacity at 30 mm. Are you sing the appropriate jaws for the job?

A piece 300 mm long is only gripped in the jaws by a short length, so you could be distorting the workpiece as well as chuck comonents. Presumably your chuck is either a 80 mm or at most 100 mm?

Push too hard and you could do some damage to the chuck, at least, if yuou haven't already!.

Maybe you should repeat your tests with something a little smaller and shorter .

The reults might be a little more realistic for a minii lathe.

0.15 mm at 300 mm is almost 6 good old Imperial thous, so close up to the chuck with a smaller diameter arbor you may find a lot less .l

You must determine where the play is.

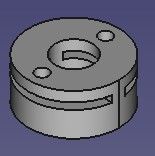

Within the chuck, the chuck / flange interface, or the spindle in the Headstock.

By exerting a lot of leverage, you may be straininbg the chuck minternals. There has to be clearance between each chuck jaw and the body; beteen each jaw and the scroll, and between the scroll and th chuck body.

Force each of those by excessive force and you will get a high reading.

You aspire to be an Engineer, not Mr Universe!

Until you find where the play is, you cannot solve the problem, even if the solutionn is to reject the lathe or the chuck.

Carry ouyt a few checks without using excess length or force, and give us the figures.

You may then get some comments which will help you decide what to do next

Howard

Nick Wheeler.