Possibly there will be local deviations around the screws.

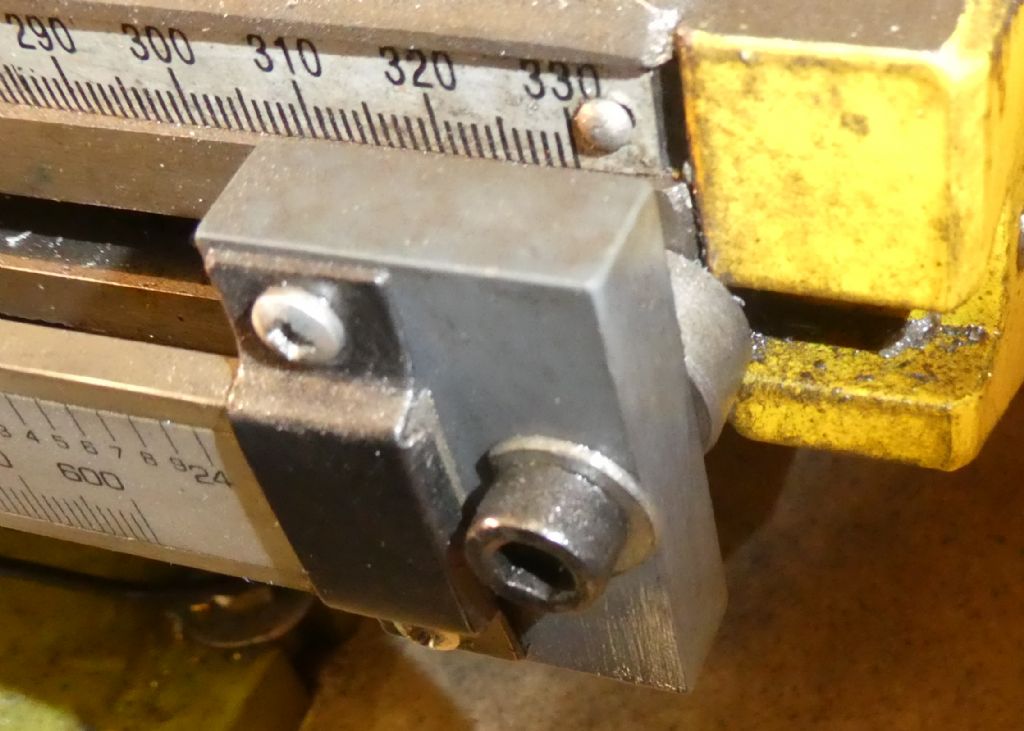

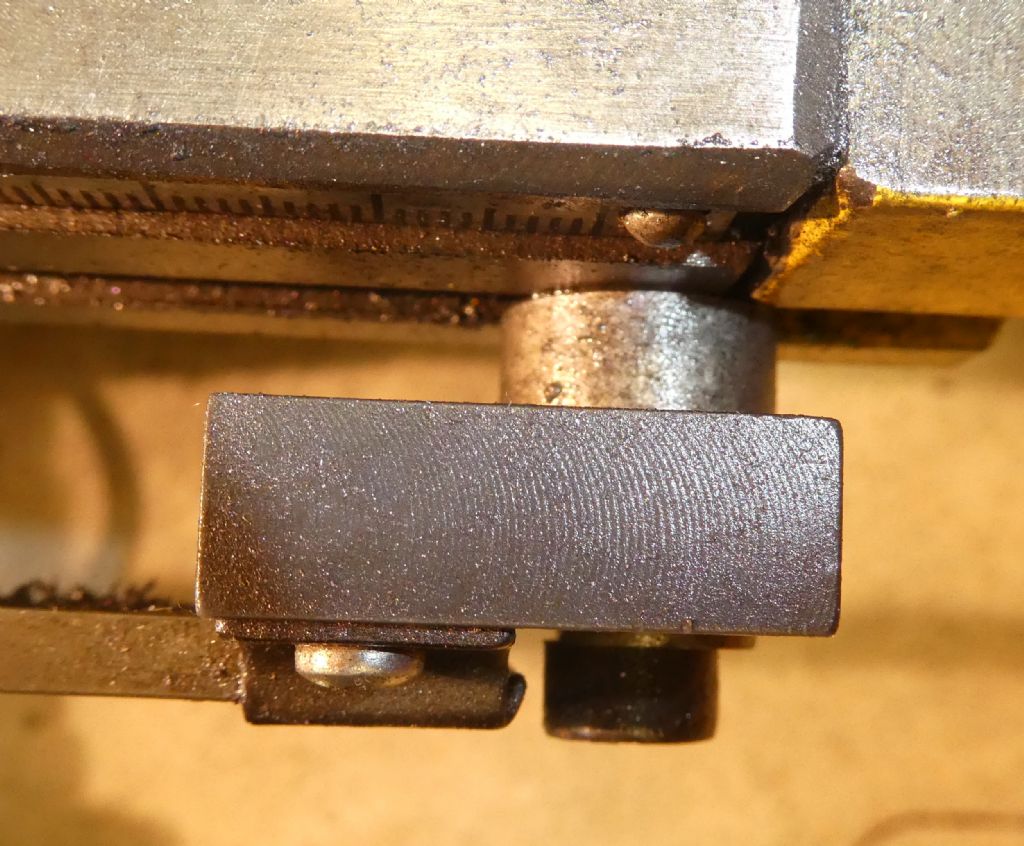

I replaced the capacitive readouts on a tool pre-setter ( a bit like this one for layout ) with magnetic scales & a budget two axis readout from M-Dro. The Swiss manufacturer of the pre-setter wanted over £3k + Vat for two replacement capacitive read heads, so approx £400 (at the time) for the M-Dro kit was a much cheaper alternative.

After fitting, I checked the positioning accuracy with slip blocks & found that neither axis was accurate & that the two axes were different in their inaccuracy. The horizontal arm was solid stainless steel & the vertical column was an aluminium extrusion with inset stainless rods for bearing surfaces – the magnetic tapes were directly applied to two different backing materials. This inaccuracy was not a problem, as the readout had parameters for linear error compensation. It didn't take long to calculate the correction values and, after a couple of refining modifications to the values, both readouts were showing accurate results against the calibrated slip block set.

The issue with local deviations due to mounting screws (if they did happen) would be that you would want a non-linear compensation, not linear – what is frequently called "pitch error compensation" on CNC machines, where the deviations are entered at a number of points along the axis using the scale reference point as a datum. While some "high end" DROs probably have this feature, it is unlikely that the budget end units would, so even if you were able to determine that such local deviations did exist, your readout unit would not allow you to compensate for them. At my last employment I had a Renishaw ML10 laser inteferometer to check and set non-linear compensation tables on CNC machines – at over £40K for the kit around 20 years ago not something readily available for the average home workshop user !

In reality I doubt that you would notice such errors if they did exist. I would suggest that you check the basic accuracy of the installation using some form of calibrated artifact(s) – say 1-2-3 blocks or slips – and, if your readout has the facility, spend a bit of time setting the linear compensations as best as you can. Then just enjoy the better overall accuracy & repeatabilty that even a slightly flawed system will give you over using the handwheel graduated dials.

Nigel B.

Mike Crossfield.