There are a lot of us called John on this thread aren’t there.

Grinding would be a really nice way to finish a crank, however most of us are not well set up for it. Ideally you want a good toolpost grinder, and you want to be a bit careful about it since you don’t really want to end up with grinding dust all over the ways. You would also need the right wheel, eg narrow enough to fit between the webs, and the means to true it up as it wears. Scaling nature is not too much of a problem with grinding, since the cutting loads are actually very small, so the job has less tendency to deflect and the rigidity of the machine itself is not likely to be a problem. Ok if a suitable toolpost grinder and a selection of wheels is available.

The idea of milling away as much as possible has the same advantage as grinding, the cutting loads are less than for turning (but more than for grinding) so the load induced deflections of the job are less. Again however we do need the right equipment for the job. This means a vertical mill with some means of mounting the crank between centres. This does not need anything too fancy, especially for small ones like this, I have done one for a Stuart Double ten on the Unimat, and in that case the rotation of the workpiece was controlled by hand with some friction added to help control things. This was with the job suspended between centres on the lathe bed, and the milling attachment mounted on the cross slide. A similar thing could be done on the Myford if a Unimat milling attachment could be borrowed, eg mount the Unimat attachment on the Myford cross slide. It looks a bit sdcary when you set it up, but the cutting loads are low enough and you can controllably take away most of the material this way. The only trouble is you won’t get a good enough finish to run a bearing on, so you have to finish in another way. But since it is all done between centres, you can transfer to the lathe for some fine finishing cuts.

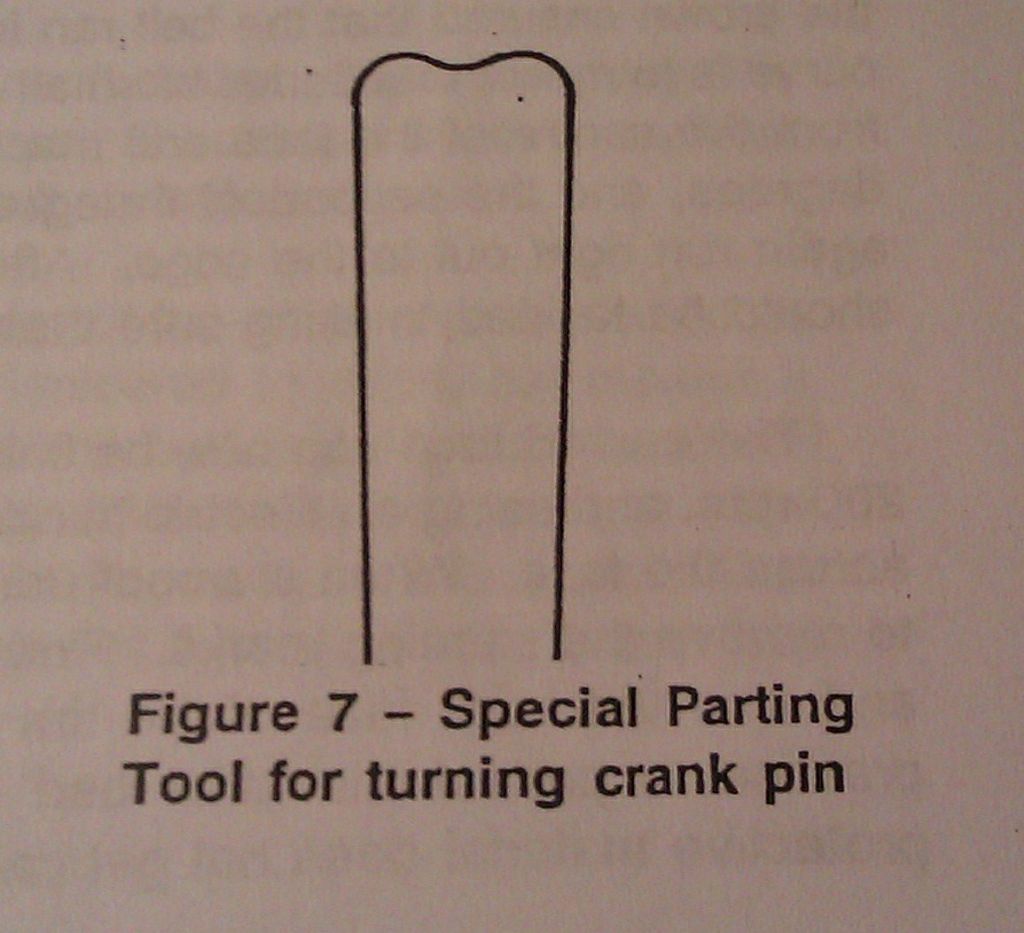

For turning on these small cranks, what we are up against is that the parting tool, even modified above, needs to be wide enough to not deflect sideways too much, and narrow enough not to cause us problems with the cutting load. No doubt we have all seen how a parting tool can cause problems in a less than rigid machine, well these little crankshafts are inherently less than rigid, and so too wide a tool will try to dig in, which can lead to disaster. I would actually use three tools if I was taking it all out with turning, a narrow left hand tool, a narrow right hand tool, and one like the diagram above for finishing.

Anyway, I will scan the article, if you like to send me a personal message with your email address I will send it to you. (Don’t put your email address in a normal posting!)

regards

John

JOHN BRIDGE 1.